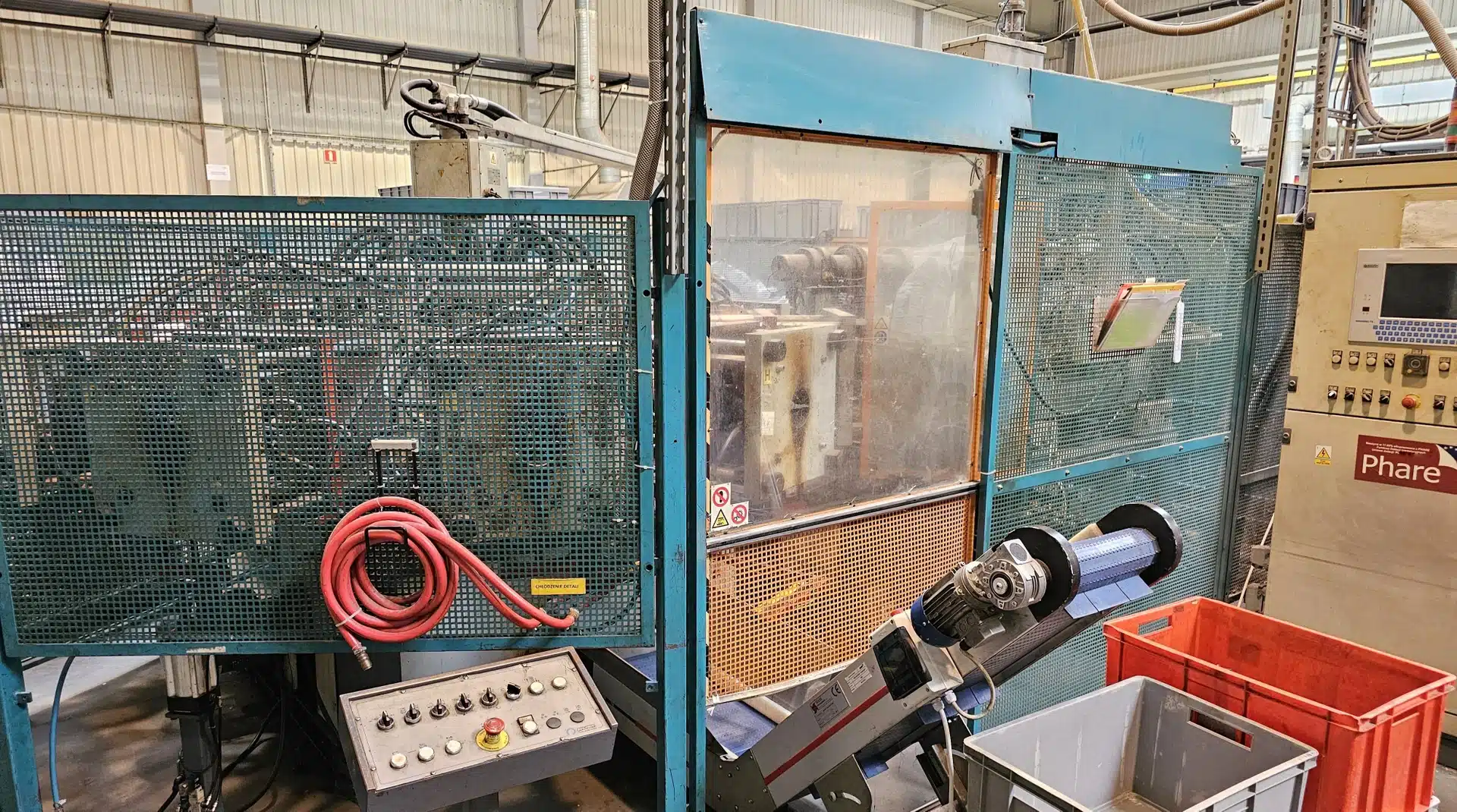

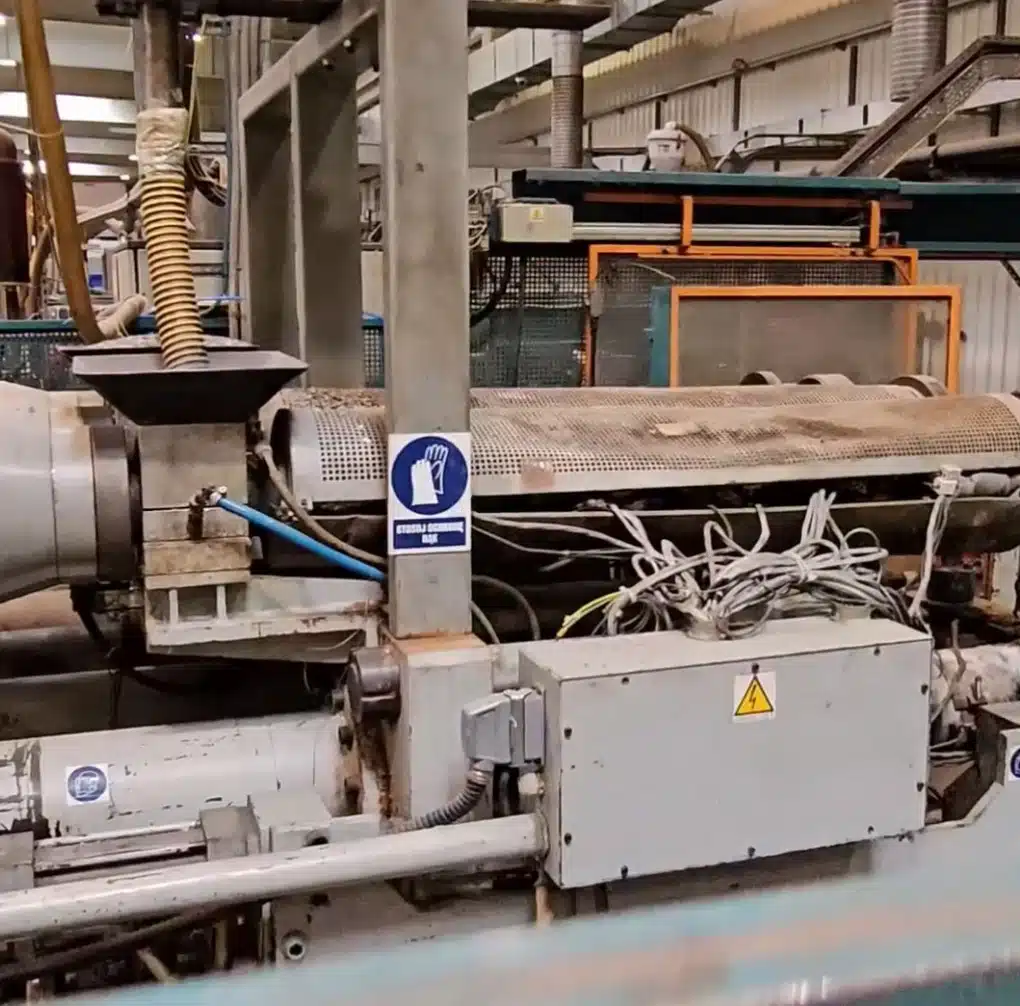

PRESMA ROTO HP 2 BIC rotary injection moulding machine was built in 2004 in Italy by PRESMA S.p.A. The machine, designed for the mass production of plastic parts, is distinguished by the use of a special rotary system that allows the use of multiple moulds of different shapes and weights at the same time. The moulds are filled one by one with plasticised plastic and then clamped with a press force of 30 tonnes. If a certain production volume is reached, it is possible to skip one or more workstations. The workpieces produced in this way are in turn distinguished by their high repeatability, durability and precision. The ROTO HP 2 BIC rotary injection moulding machine weighs 17800 kg.

Technical specifications of the PRESMA ROTO HP 2 BIC injection moulding machine

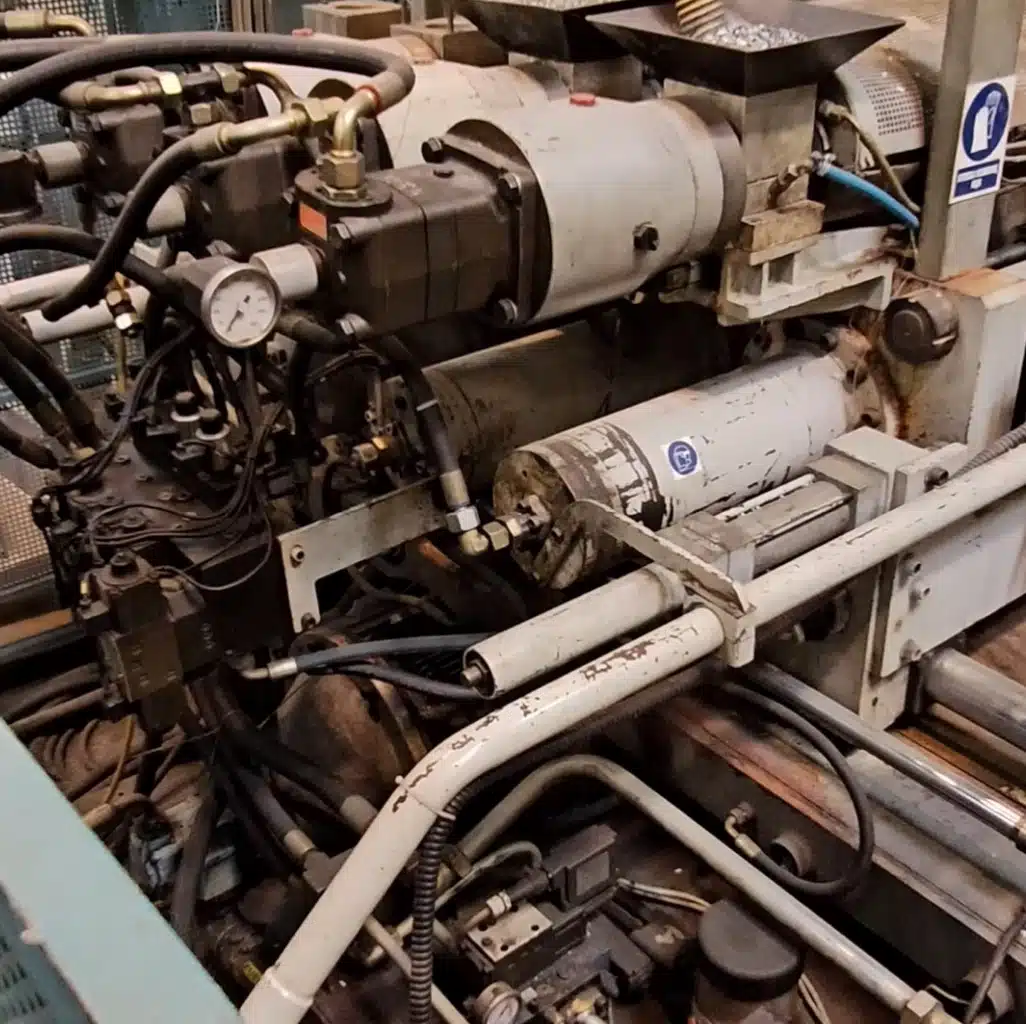

- maximum clamping force: 30 t (300 kN)

- EE1 screw diameter: 62 mm

- EE2 screw diameter: 62 mm

- screw length/diameter ratio: 21 L/D

- maximum injection pressure: 575 bar

- EE1-PP injection weight: 900 g

- EE2-PP injection weight: 900 g

- clamping platen size (W x H): 475 x 490 mm

- maximum mould height: 300 mm

- minimum mould height: 180 mm

- distance between columns: 350 x 350 mm

- centering ring diameter on fixed table EE1: 95 mm

- number of heating zones: 6+6+1

- cylinder heating power: 94 kW

- oil tank capacity: 600 l

- pump motor power: 37 kW

- total power: 148 kW

- dimensions (L x W x H): 6200 x 4600 x 2400 mm

- weight of PRESMA ROTO HP 2 BIC machine: 17800 kg