BYSTRONIC BySprint FIBER 6520 fiber laser was manufactured in 2016 in Switzerland. The extremely high-tech machine achieves the highest productivity and precision in cutting thin metal sheets made of among others carbon steel, copper and brass, thanks to the use of innovative fibre optic technology. The workpieces are cut by a specially designed cutting head with an integral capacitive sensor that receives a high-quality beam with a power of 6 kW. The ByPos Fiber function adapts the focal length to the material and production range, resulting in extremely smooth edges without any irregularities.

Designed for maximum user comfort, the laser cutting machine design features a large work table of 6500 length and 2000 mm width with micro-welds to support small, long and thin parts. The entire work area also features a special protection system designed to provide the user with a high level of safety during the performed work. The machine axes are driven by a low-speed, high-torque direct drive, guaranteeing ultra-fast acceleration and long service life.

The BYSTRONIC fibre laser is equipped with a state-of-the-art BYSTRONIC ByVision CNC control with touchscreen and remote control for modifying cutting parameters, saving cutting plans and automatically activating, deactivating and setting micro joints. Low loading times for cutting plans reduce downtime and increase machine productivity. The FIBER laser BySprint FIBER 6520 weighs 21500 kg.

Technical specifications of the BYSTRONIC BySprint FIBER 6520 laser cutting machine

- processed materials: carbon steel, copper, brass

- laser beam power: 6 kW

- maximum workpiece thickness (carbon steel): 20 mm

- work table area (L x W): 6500 x 2000 mm

- laser beam length: 1060-1080 nm

- automatic selection of cutting parameters (ATS)

- capacitive height measurement

- common edge cutting

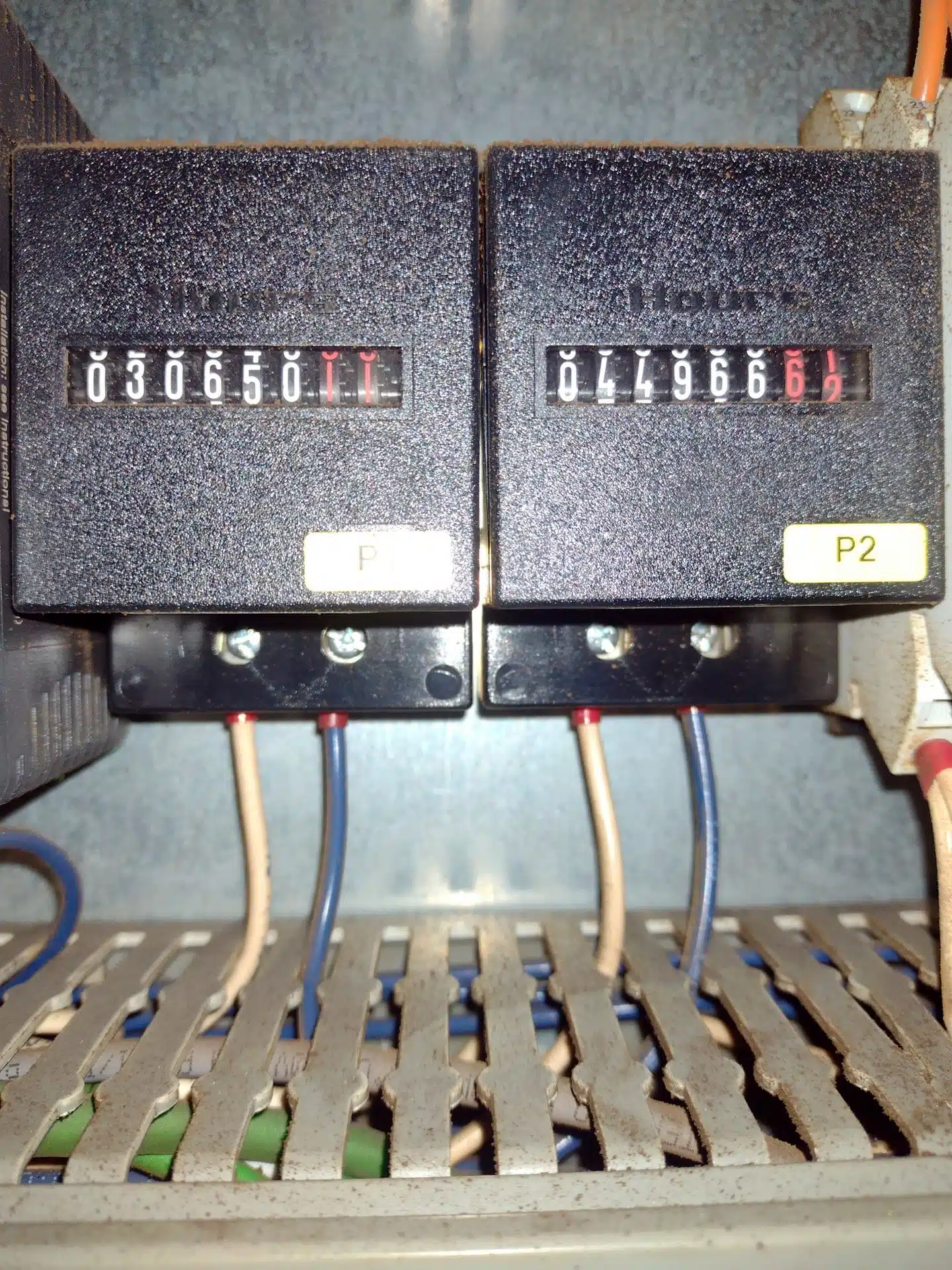

- cutting time: 30650 h

- switch-on time: 44966 h

- machine weight: 21500 kg

Equipment of the BySprint 6520 laser

- CNC control: BYSTRONIC ByVision

- ByPos Fiber function (automatic focal length adjustment)

- cutting head with integral capacitive sensor

- automatic table changer

- dust extraction system

- protective system over the entire work area

- automatic nozzle changer

- cooling unit

- complete control cabinet

- remote machine control

- UPS power supply

- filters

- waste collection trolley

- DVD station

- USB port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe