The KIMLA HSM BFN 1015 Linear CNC machining center was manufactured in 2017 in Poland. It is equipped with a T-slot table with a slot spacing of 25 mm. The range of movements in the X and Y axes is 1000 mm and 1500 mm, respectively, and in the z axis, 300 mm. The machine has a HSD 12kW ISO30 spindle rotating at 24,000 rpm. The KIMLA CNC milling machine has a wide range of equipment, which includes, among others, a control cabinet, a rotary tool magazine and a tactile, wired scanning head. This head enables homing and 2D and 3D scanning. The CNC machining center is designed for machining cutting materials, including engraving cutters, arbor mills and drills. The machine has a working area of 1000x1500x300 mm, which enables the production of stamping dies, injection molds, steel and aluminum dies, as well as the processing of casting models. Instead of traditional ball screws previously used in CNC machines, linear drives have been used, the elements of which do not wear out, and thus do not deteriorate the quality of the cut during operation. Moreover, these drives transmit the force solely by means of a magnetic field, and therefore contact and frictionless. The KIMLA CNC milling machine is suitable for precision applications where very high positioning accuracy is required. The machining center uses measuring systems with a resolution of 1 nm and an accuracy of 5 micrometers per meter, which is a solution practically unavailable for many people and extremely expensive. The CNC machining center has an automatic tool change with a magazine, in a gate configuration with a traveling table.

Technical data of the CNC milling center KIMLA HSM BFN 1015 Linear

– X x Y range of movements: 1000 x 1500

– Z range of motion: 300 mm

– spindle: HSD 12kW 24000rpm ISO30

– table type: T-slot

– table groove spacing: 25mm

– spindle working time: 1480 hours

– 3D control module

– drive: linear

– technology: High Speed Machining

– power supply: 400 V / 50 Hz

– power: 16 kW

– pressure: 8 bar

– weight: 6500 kg

Accessories for a CNC gantry milling machine KIMLA HSM BFN 1015 Linear

– tool correction sensor

– control cabinet

– control computer

– automatic oil mist

– automatic tool change

– rotary tool magazine

– operator protection cabin

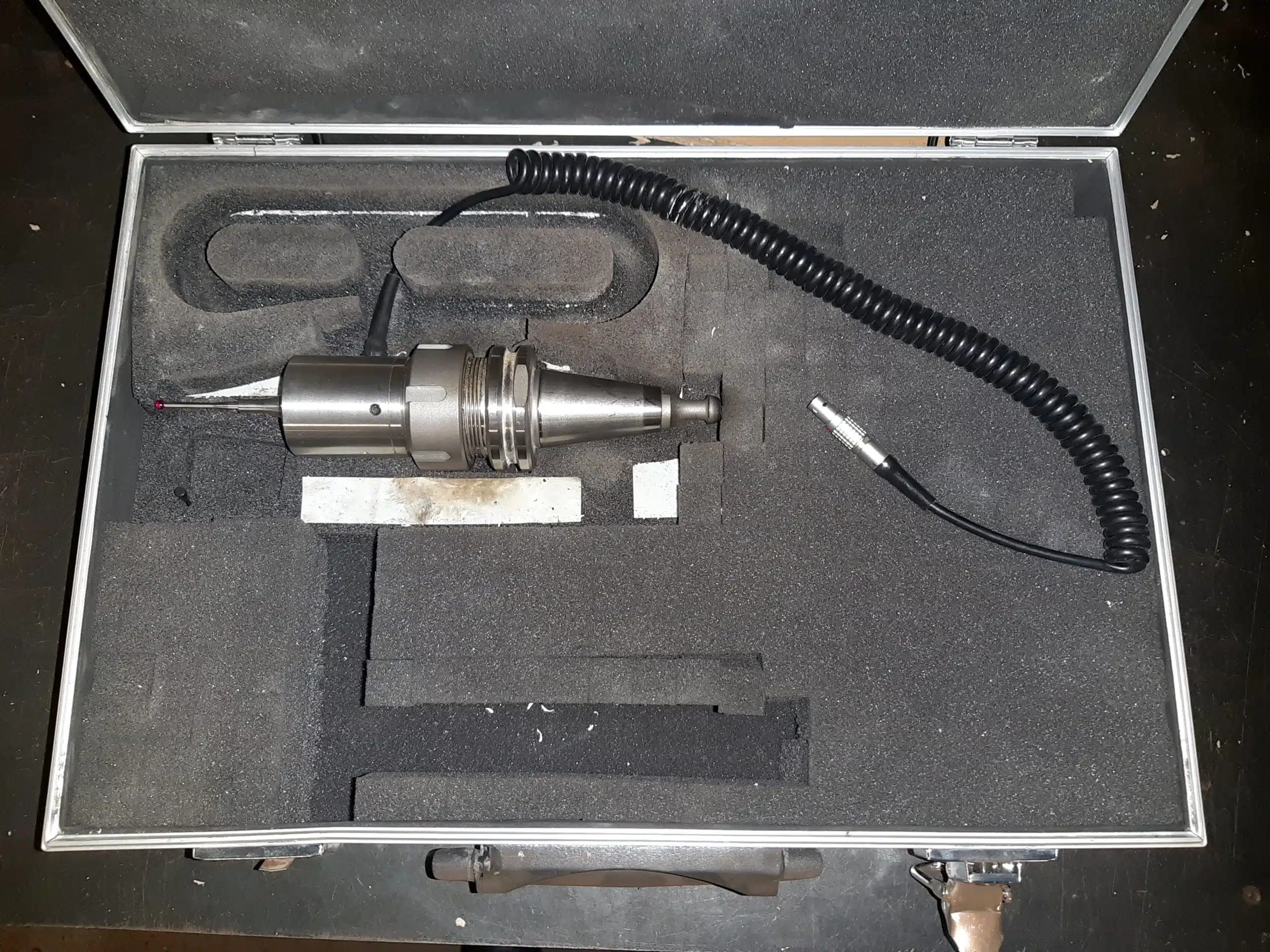

– scanning, touch, wired head (homing, 2D and 3D scanning)