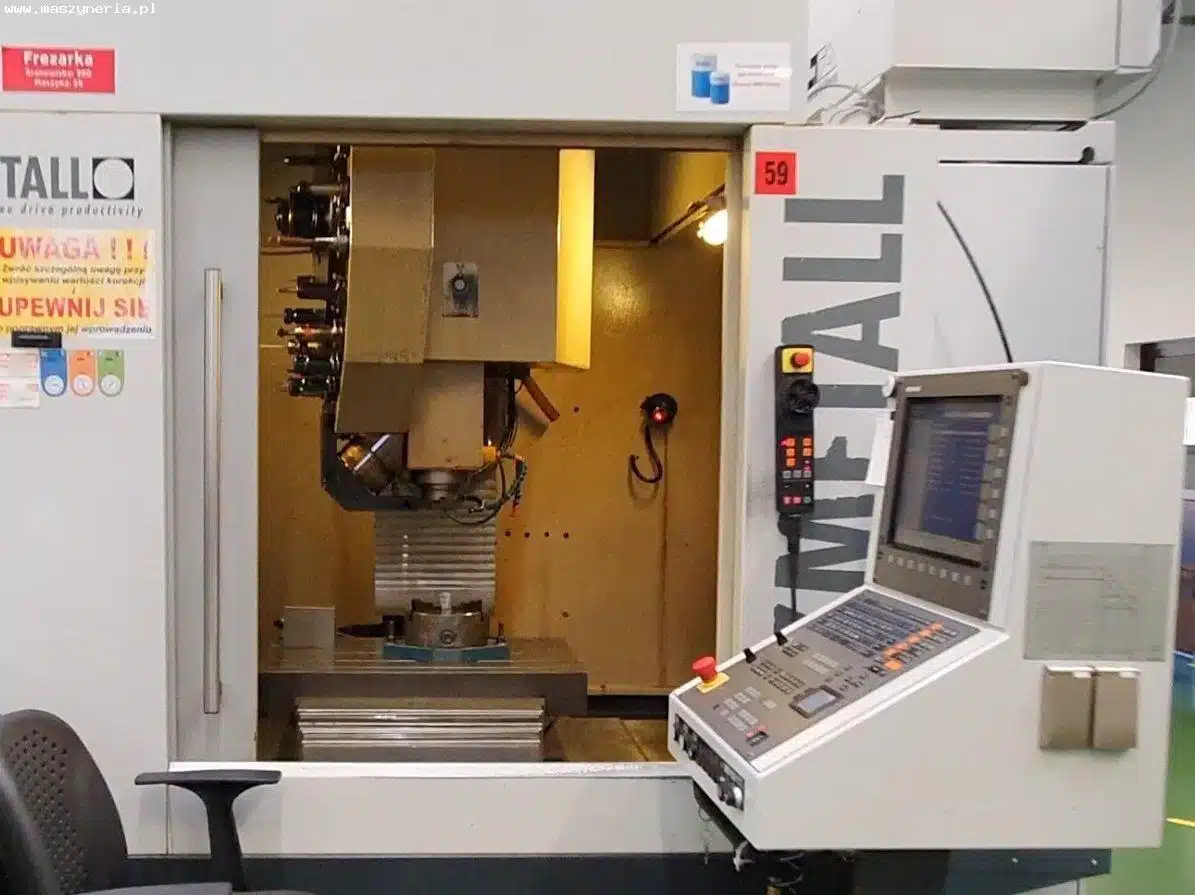

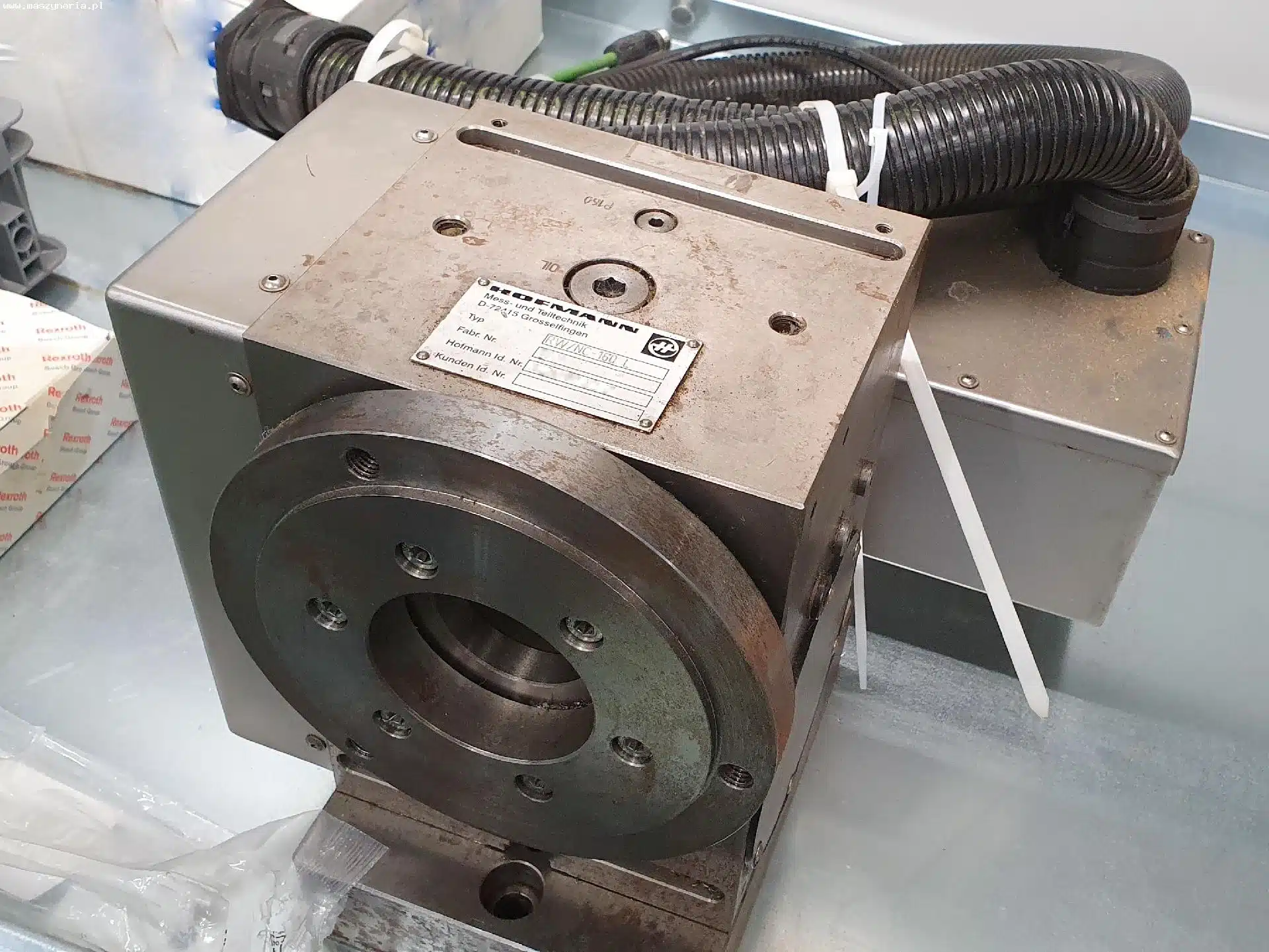

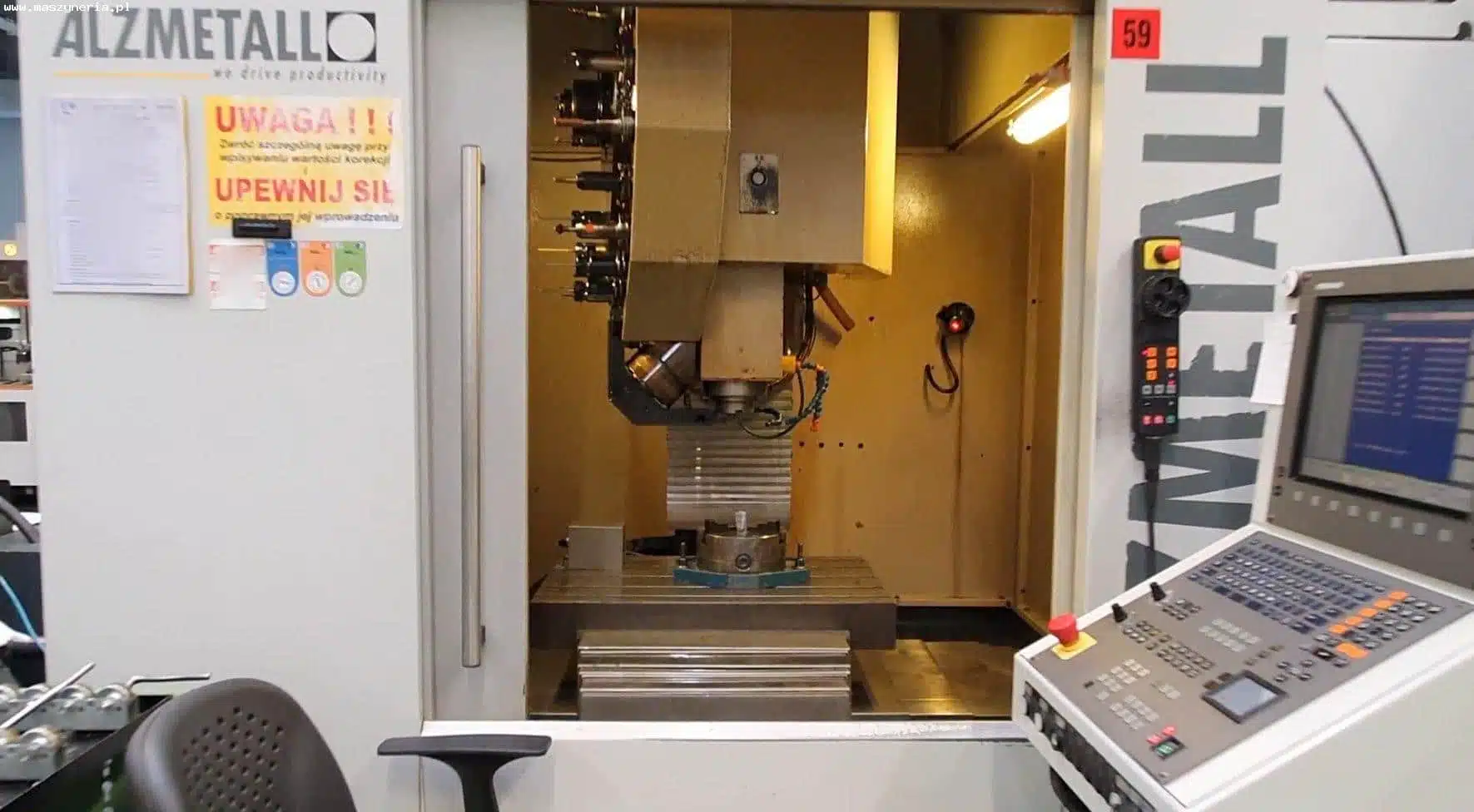

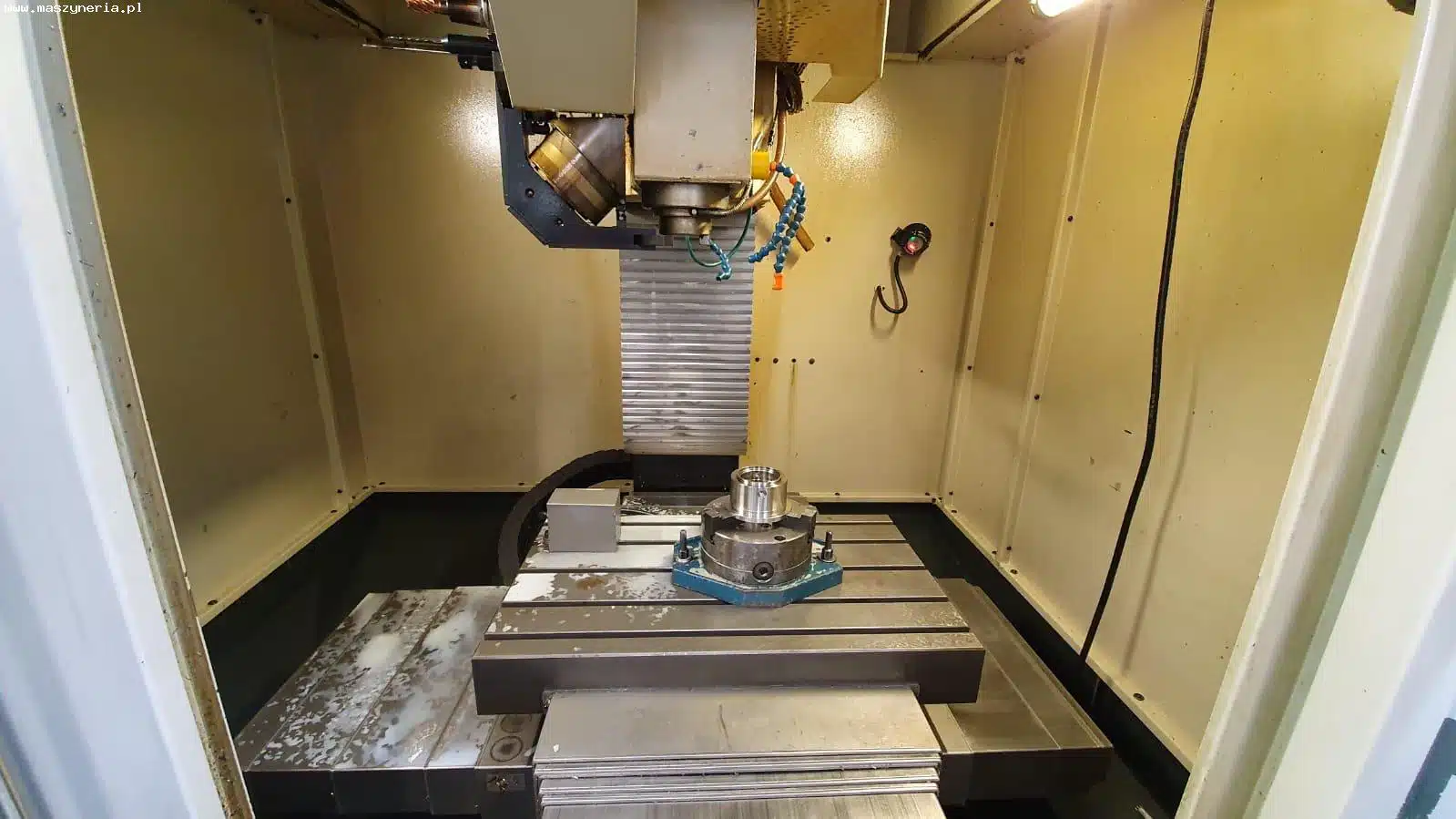

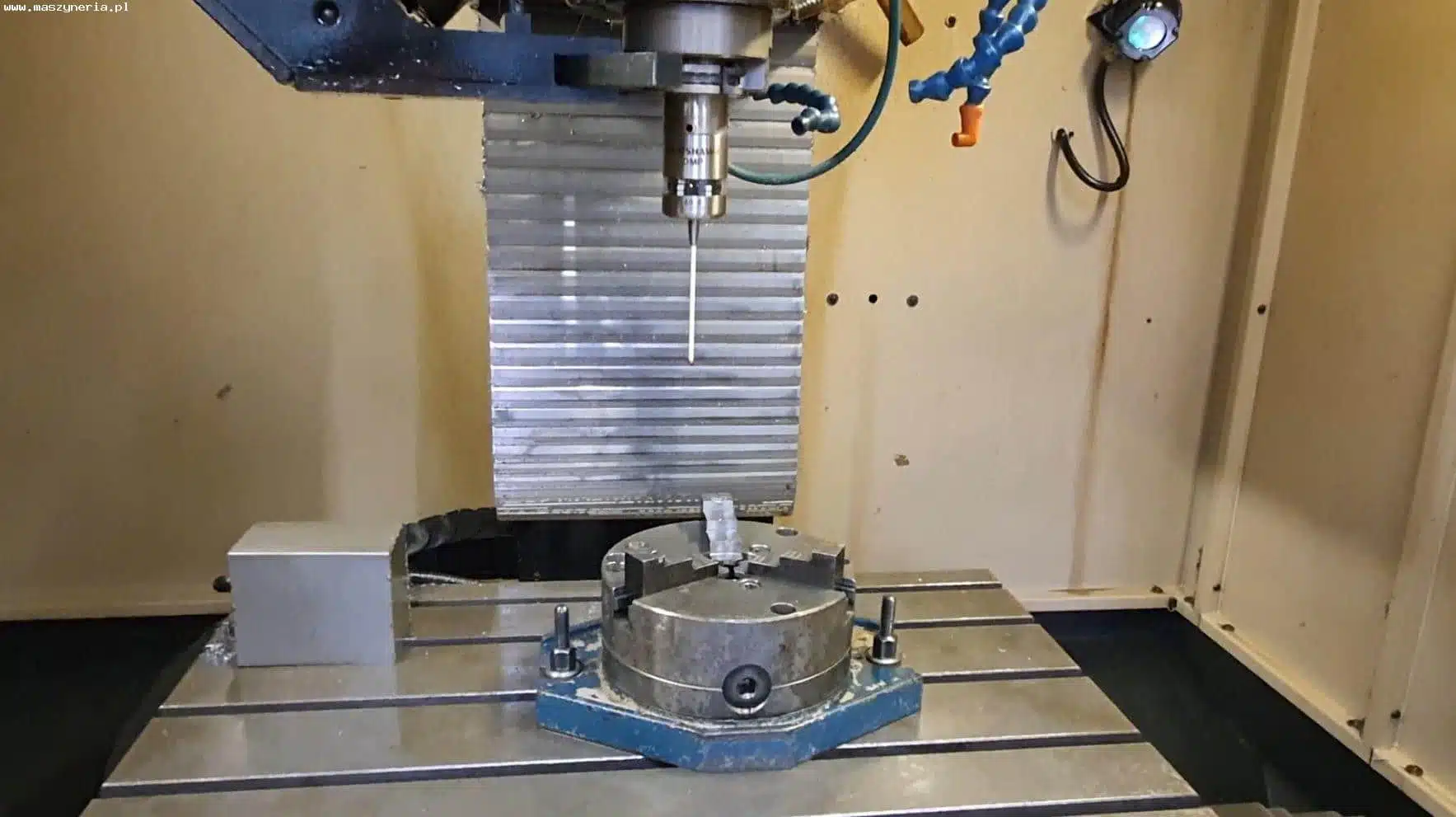

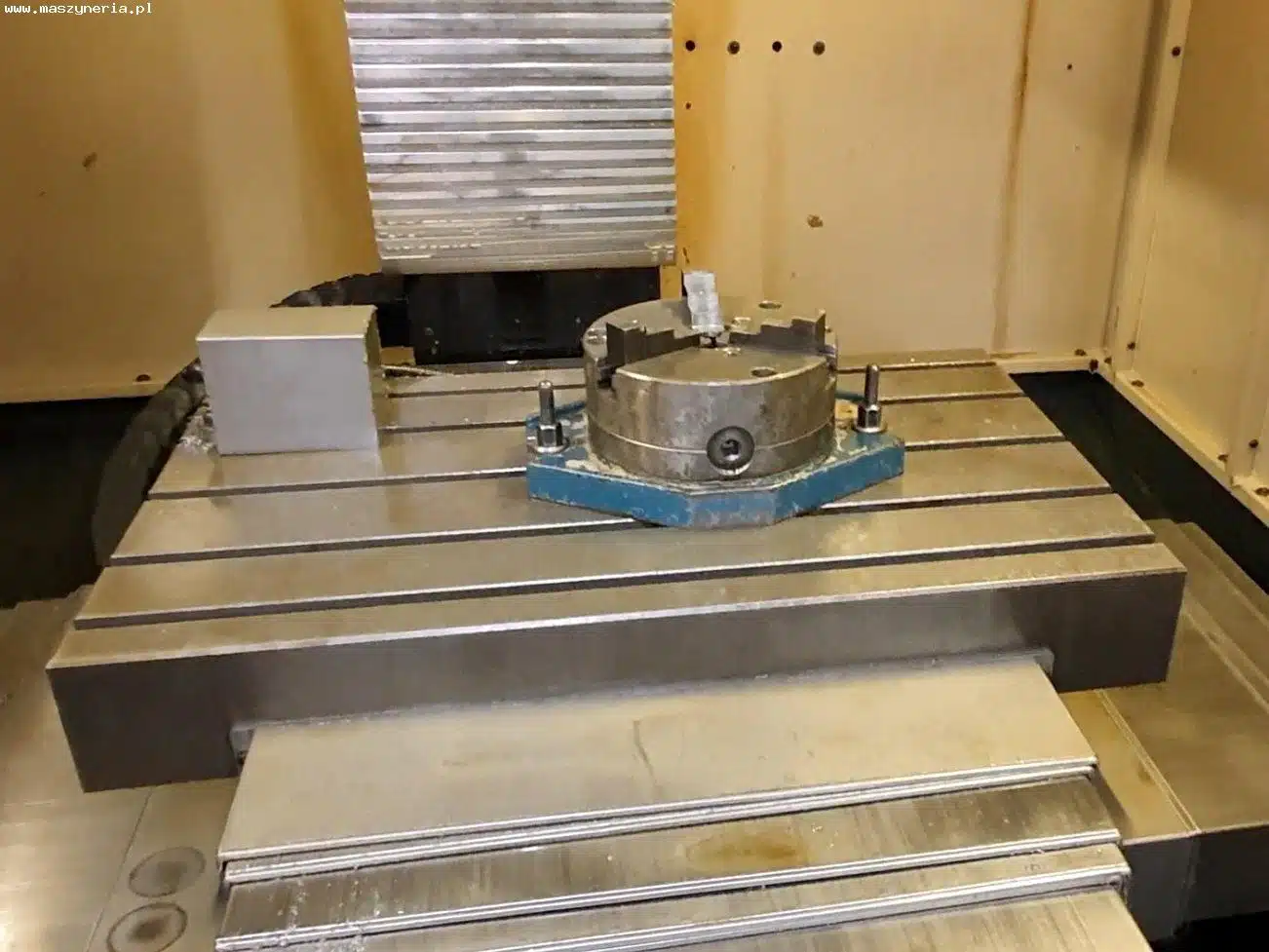

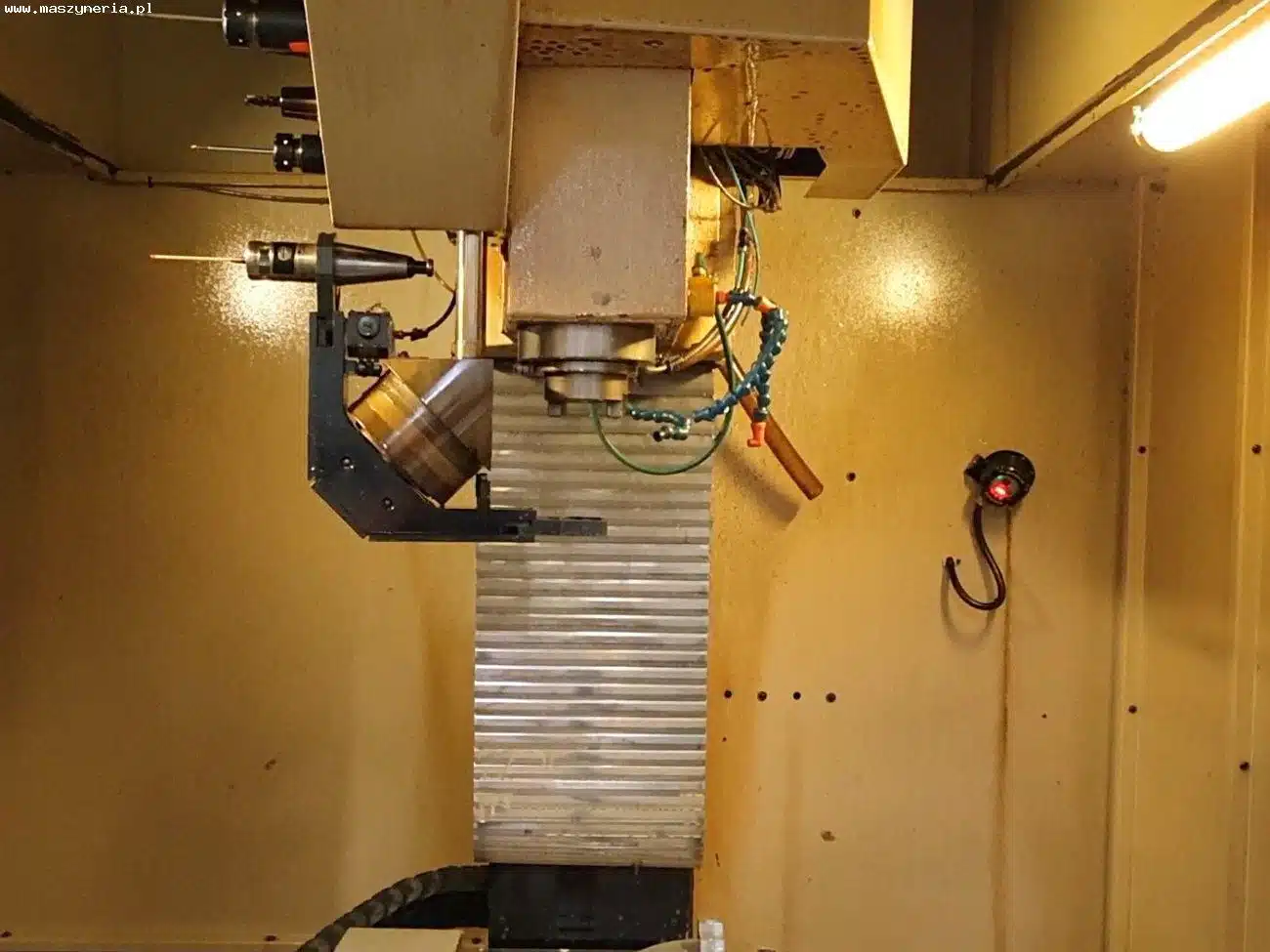

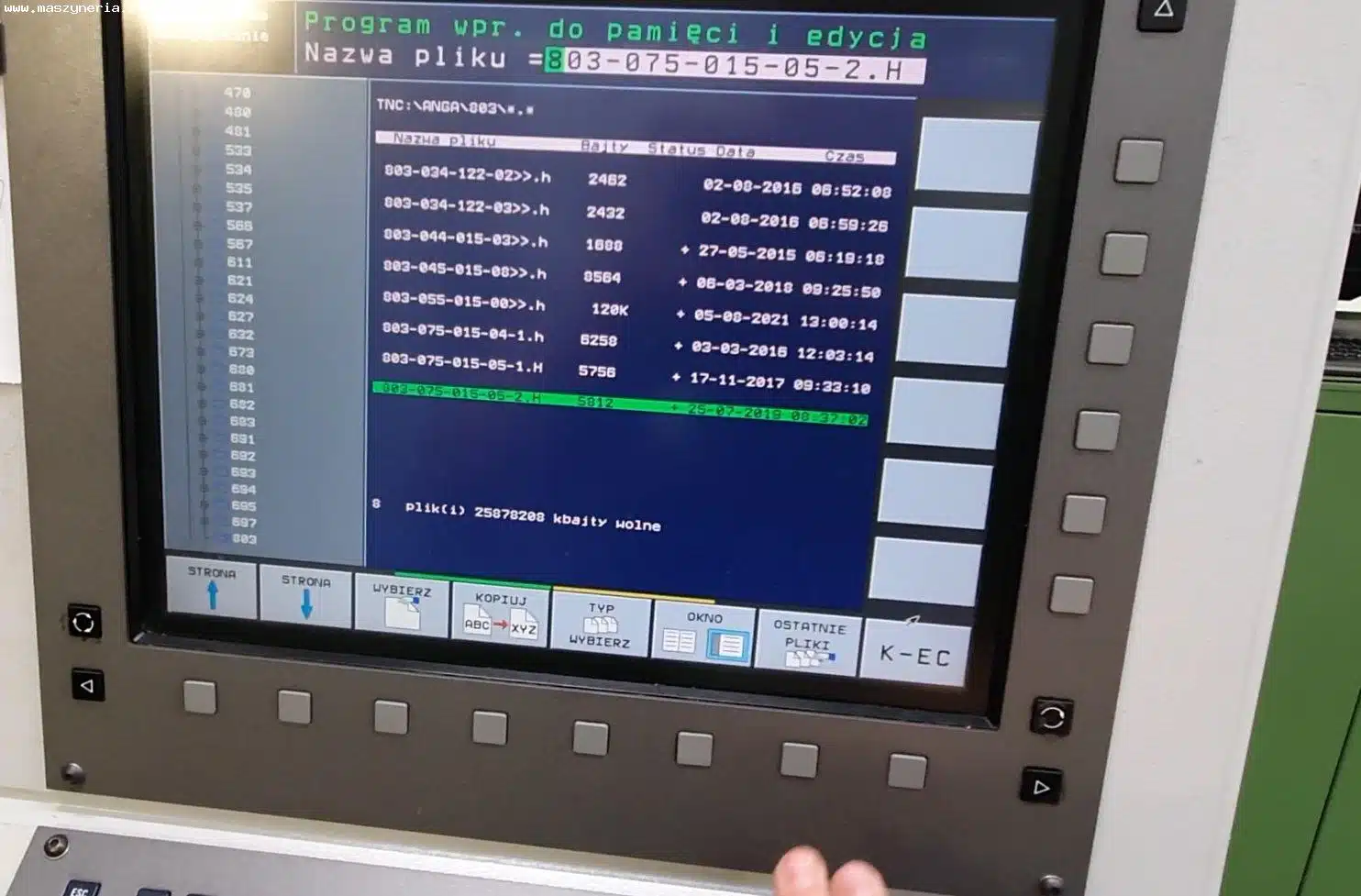

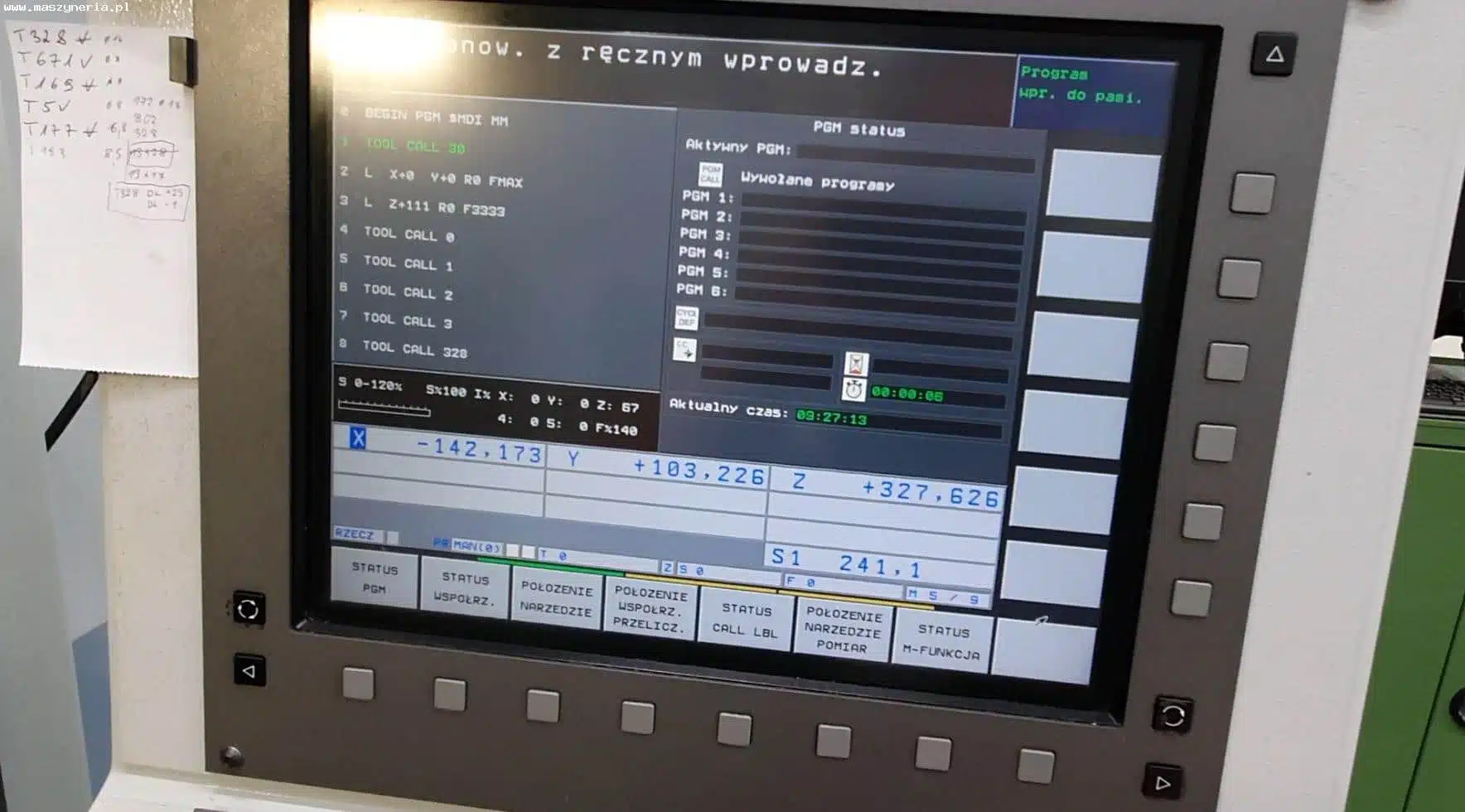

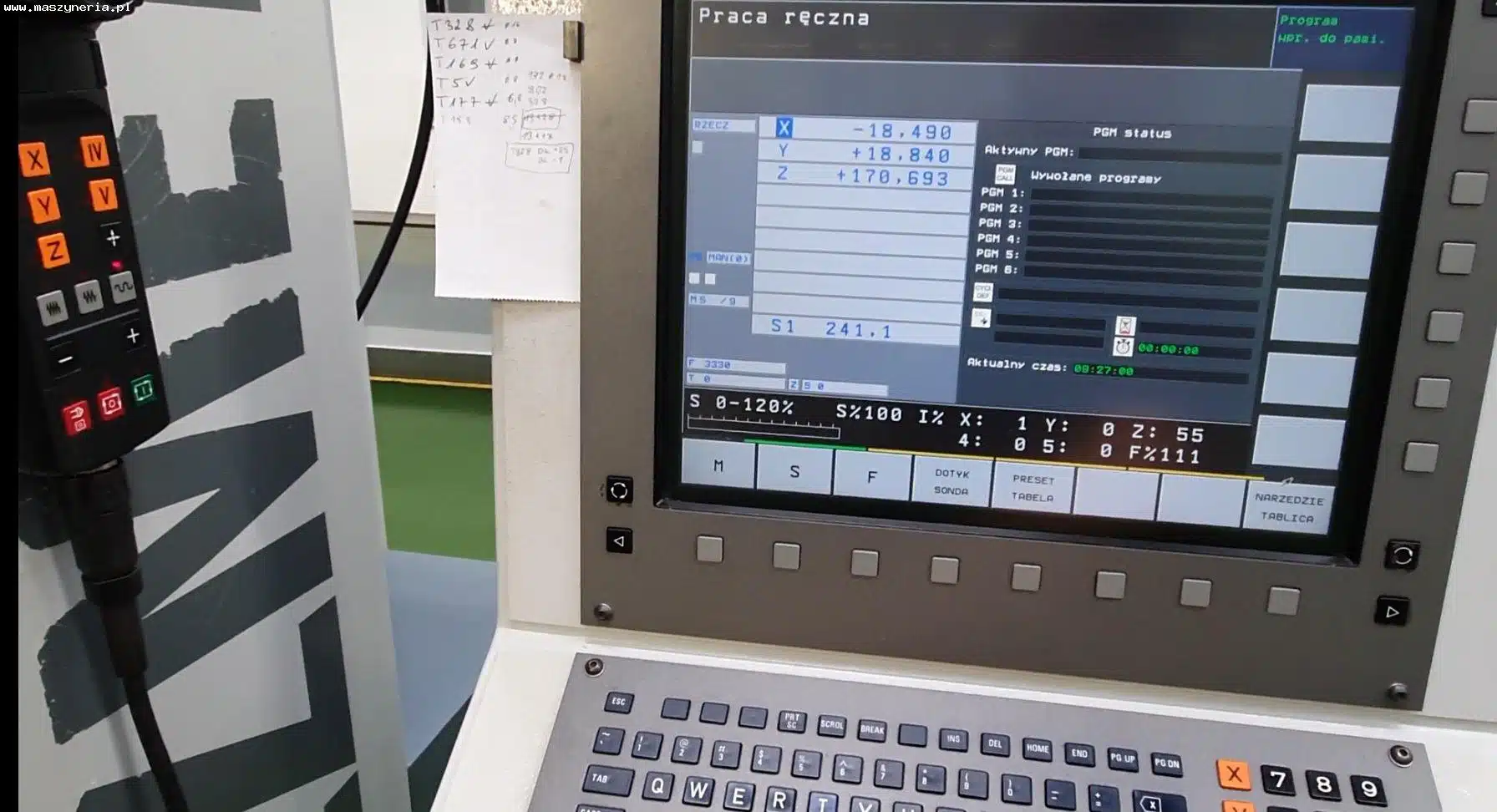

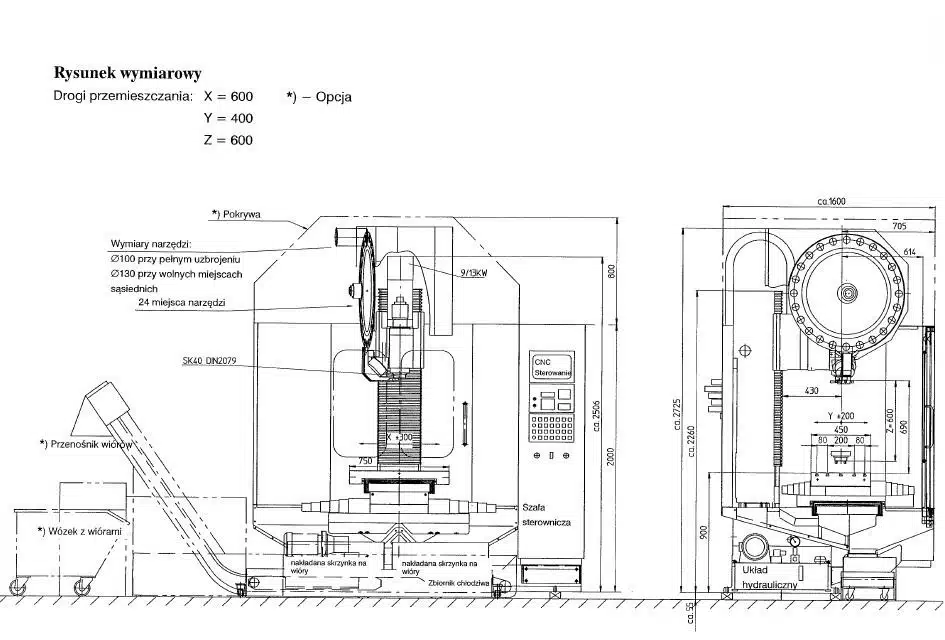

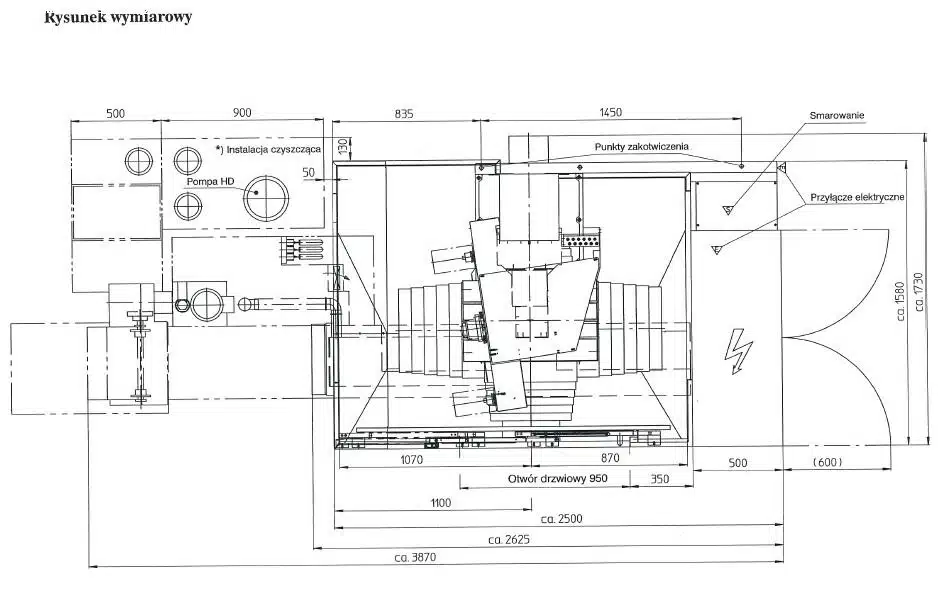

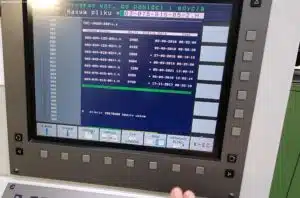

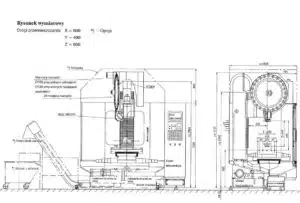

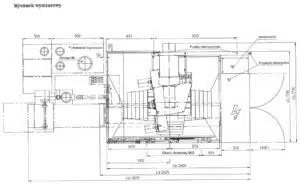

The ALZMETALL CS 600 vertical milling center 4 AXIS was produced in 2006. The machine works in three axes (X, Y, Z) with maximum axis travels of 600 mm, 400 mm and 600 mm, respectively, while it is equipped and offered at a price with fourth rotary axis HOFMANN RW / NC 160 L (ready to install) and RENISHAW OMP-40 probe and RENISHAW TS 27R plug to measure the length of tools. The milling center is equipped with a Heidenhain 530 CNC control system and can process metals up to 500 kg. The machining center was regularly serviced, elements were replaced, i.e. modification of the power supply for mounting the 4-axis rotary axis, replacement of the grabber / tool changer, replacement of the spindle motor, or replacement of the drive gear of the warehouse drum.

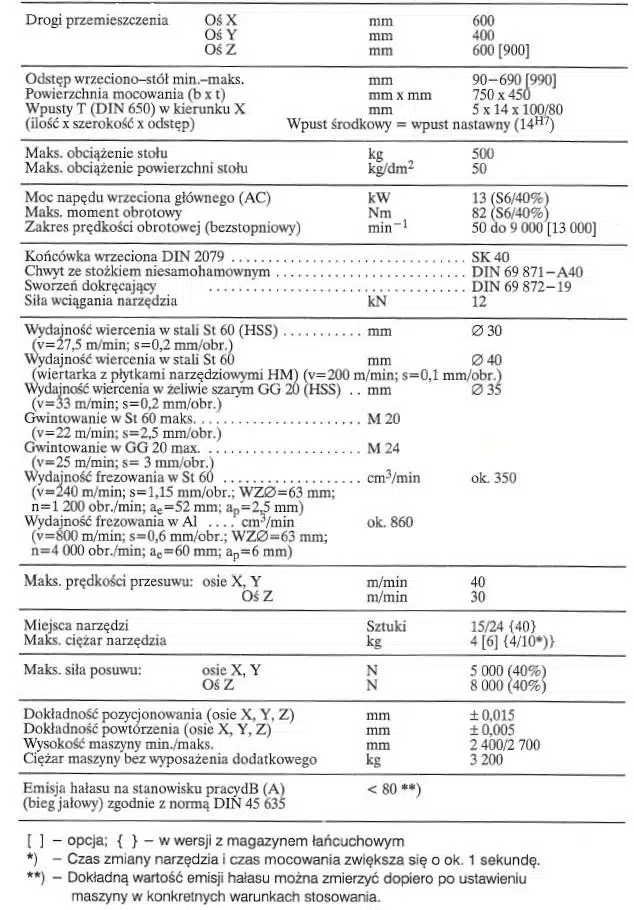

Technical parameters of the ALZMETALL CS 600 CNC milling machine

– maximum shifts in the X / Y / Z axes: 600/400/600 mm

– maximum travel speed in the X / Y / Z axes: 40/40/30 m / min.

– maximum feed force in the X / Y / Z axes: 5000 / 5000/8000 N

– minimum distance between the spindle and the table: 90 mm

– maximum distance between the spindle and the table: 690 mm

– maximum table load: 500 kg

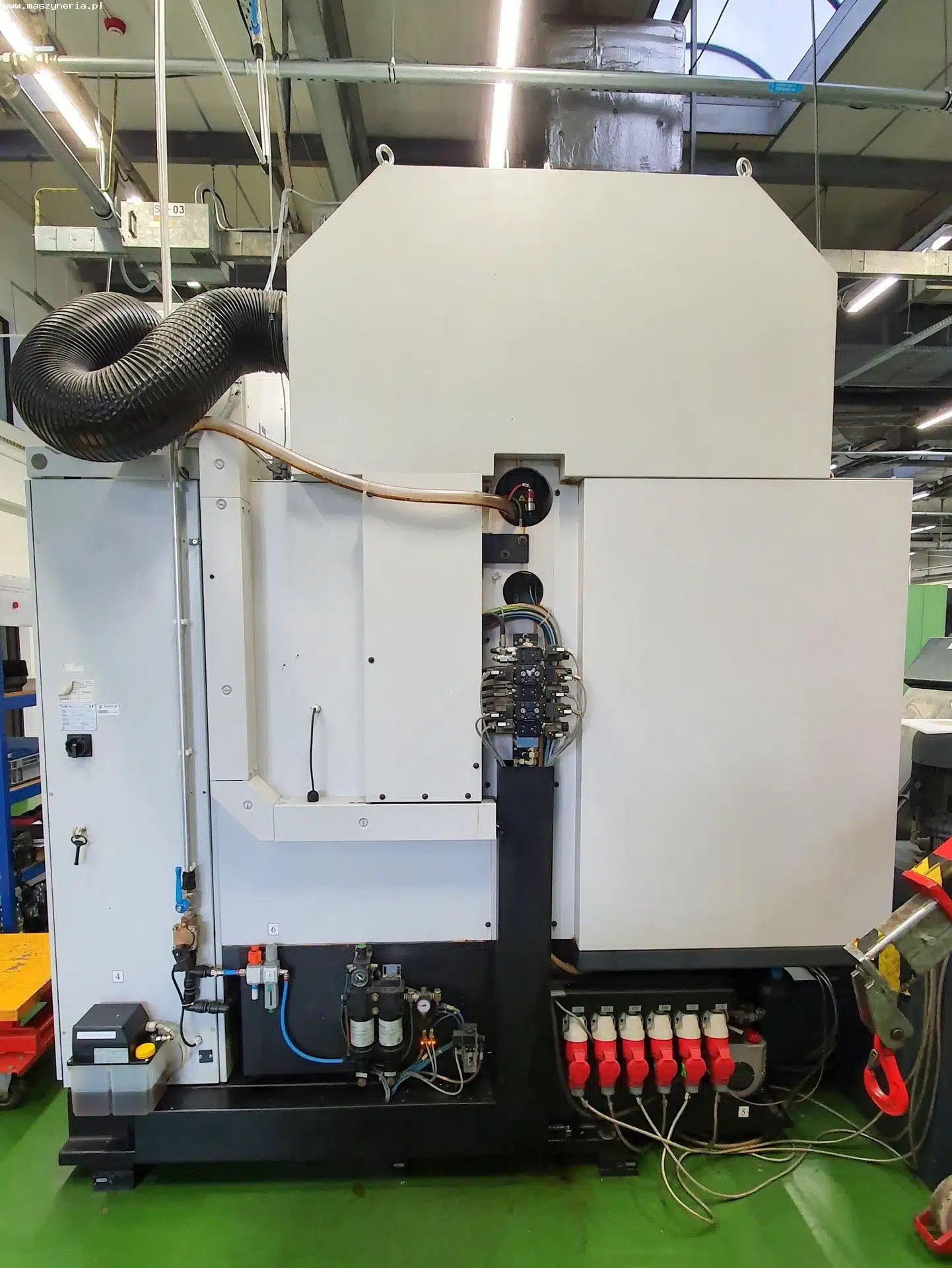

– machine height: 2700 mm

– weight of the machine without additional equipment: 3.2 t

– main spindle drive power (AC): 13 kW

Accessories for the ALZMETALL CS 600 CNC milling machine

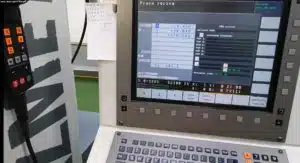

– CNC control: HEINDENHAIN 530

– HOFMANN 4th rotary axis

– probe for measuring the workpiece RENISHAW OMP-40

– mushroom for measuring tools RENISHAW TS 27R

– tool mounting: SK-40