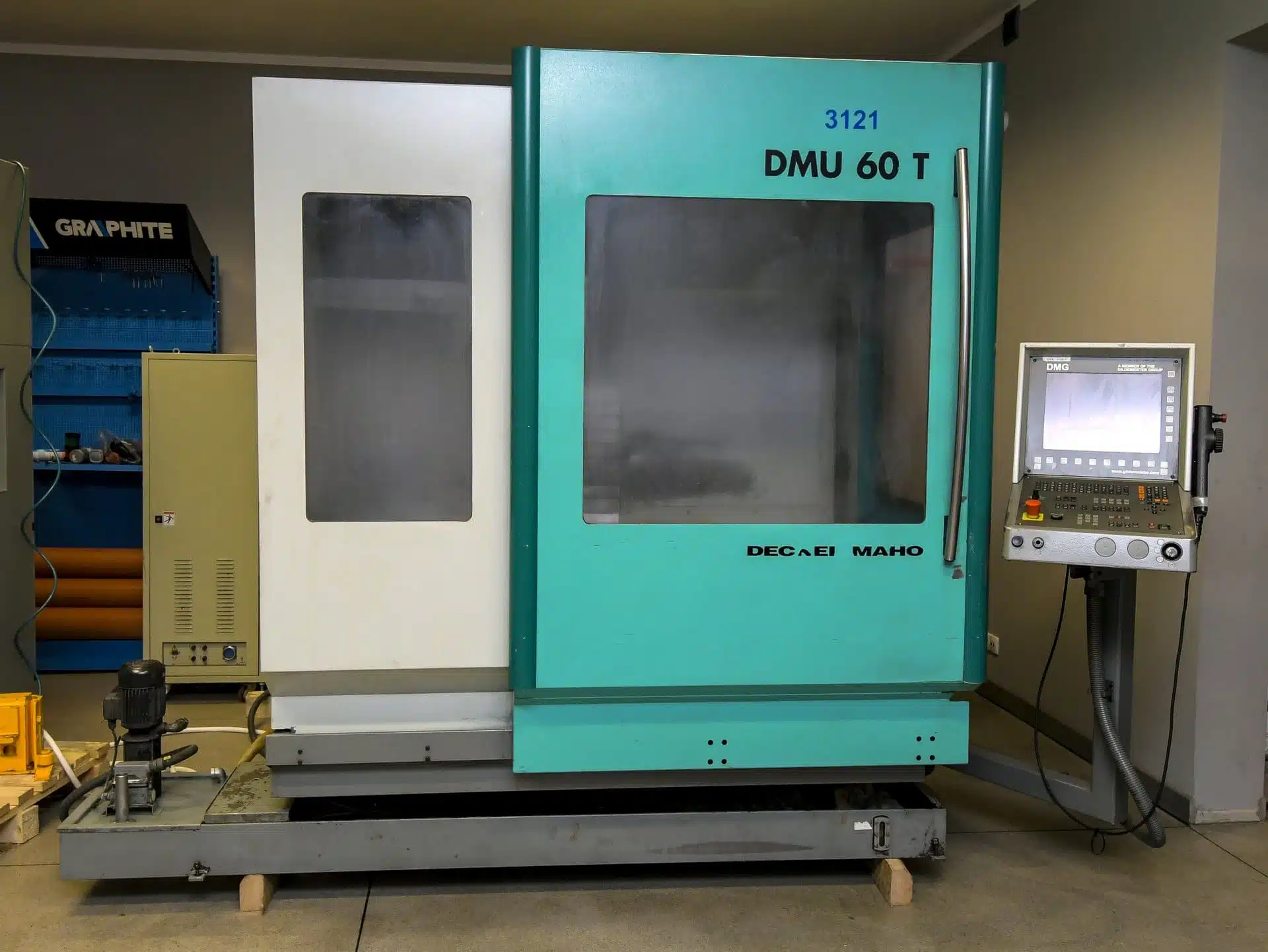

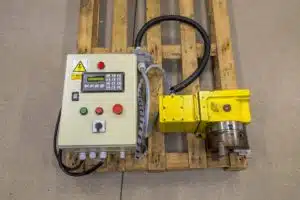

The DECKEL MAHO DMU 60 T vertical machining center was manufactured in 1998 by DMG Mori Seiki AG in Germany. The machine is equipped with rulers, HEIDENHAIN 426 CNC control and NIKKEN support table, which serves as the 4th axis. The support table is numerically controlled by means of individual control. The milling machine also has a detachable head, thanks to which it is possible to mill horizontally. The spindle of the machine rotates at a speed in the range from 20 to 6300 rpm, and worked 12 thousand man-hours in total. hours. The feeds in the X / Y / Z axes are 600, 525 and 500 mm, respectively. The working table has the dimensions (L x W) 900 x 500 mm, and its load can be 350 kg.

Technical data of the DECKEL MAHO DMU 60 T milling machine

– CNC control: HEIDENHAIN 426

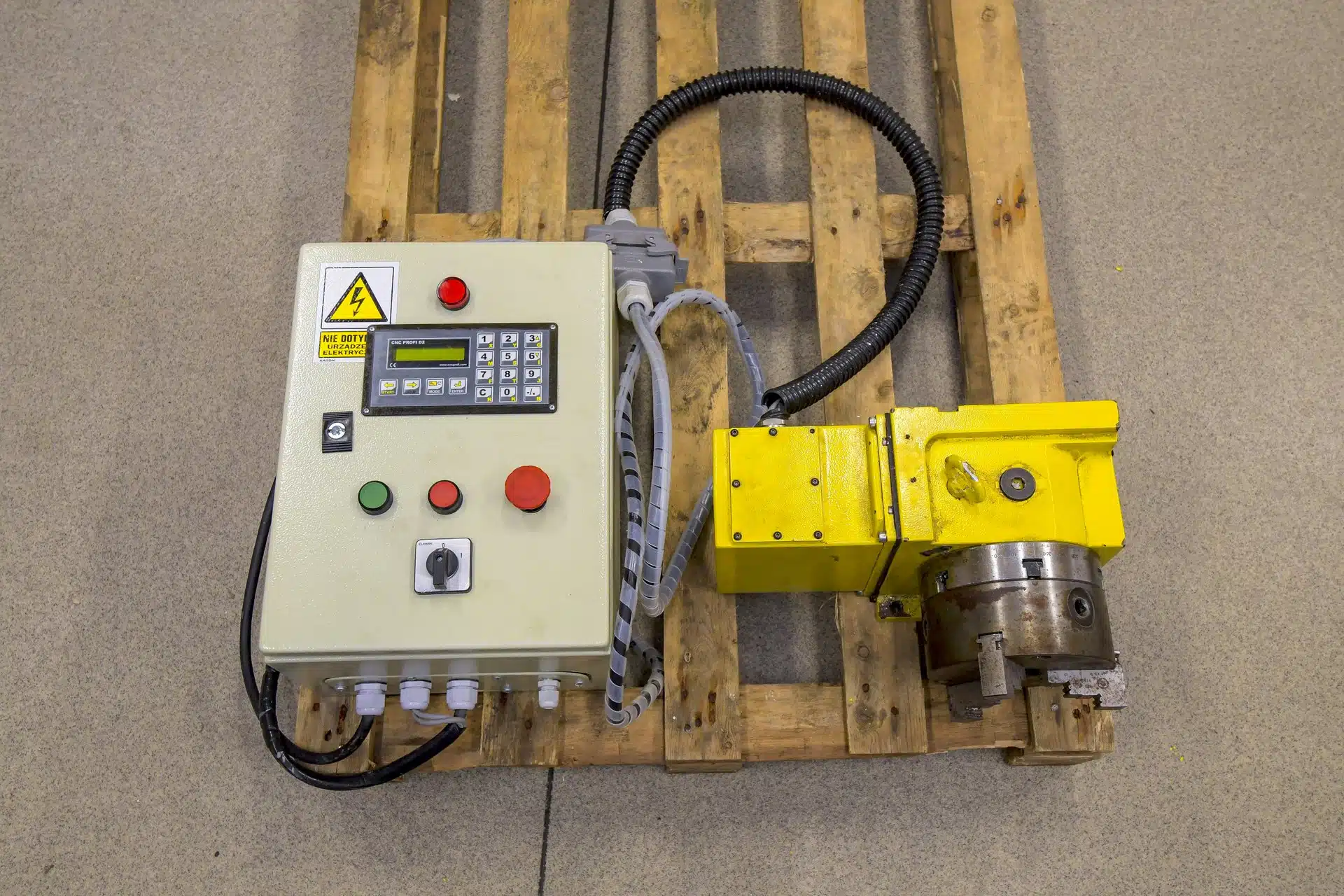

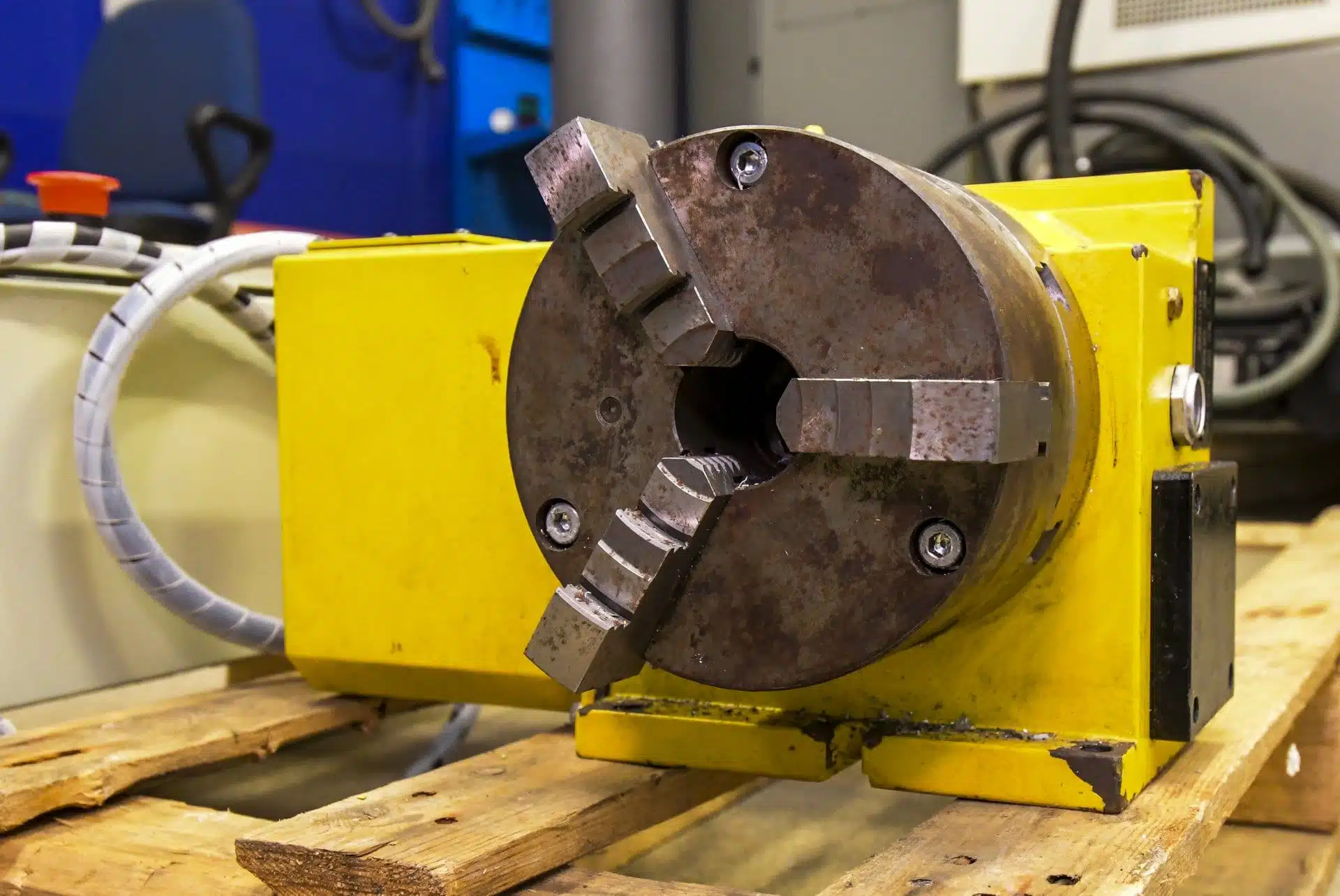

– support table NIKKEN (4th axis)

– dimensions of the working table (length x width): 900 x 500 mm

– table load: 350 kg

– maximum feeds in the X / Y / Z axes: 600/525/500 mm

– rapid feeds in the X and Y axis: 18 m/min

– rapid feeds in the Z axis: 17 m / min

– spindle speed range: 20 – 6300 rpm

– vertical, manual and rotary milling head (X, Y, Z axis): 20 – 10,000 mm/min

– number of T-slots: 8

– spacing of T-slots: 63 mm

– tool holder: SK 40

– spindle: SK 40 (8 pcs.)

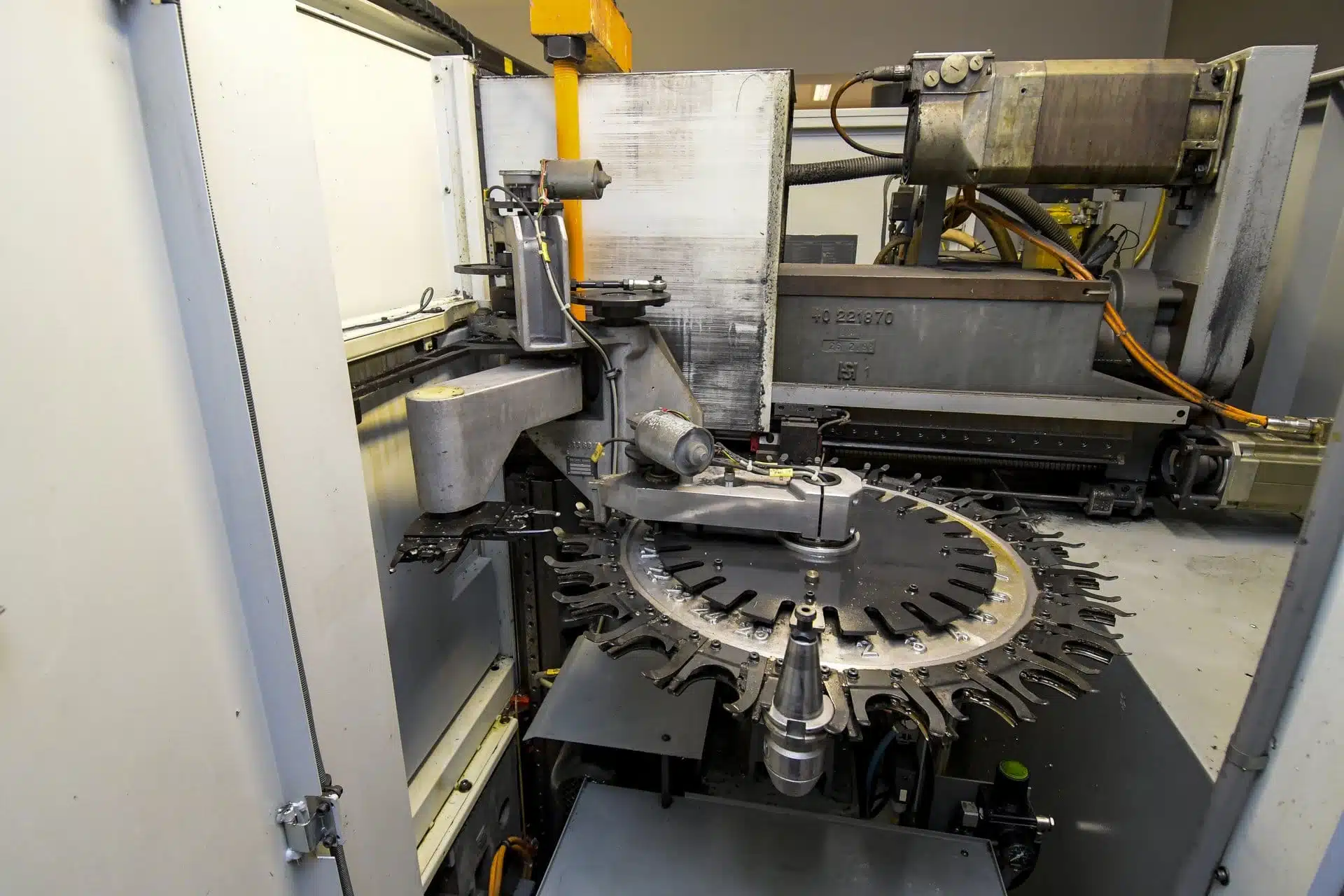

– tool changer: 25 pcs.

– bathtub with a pump