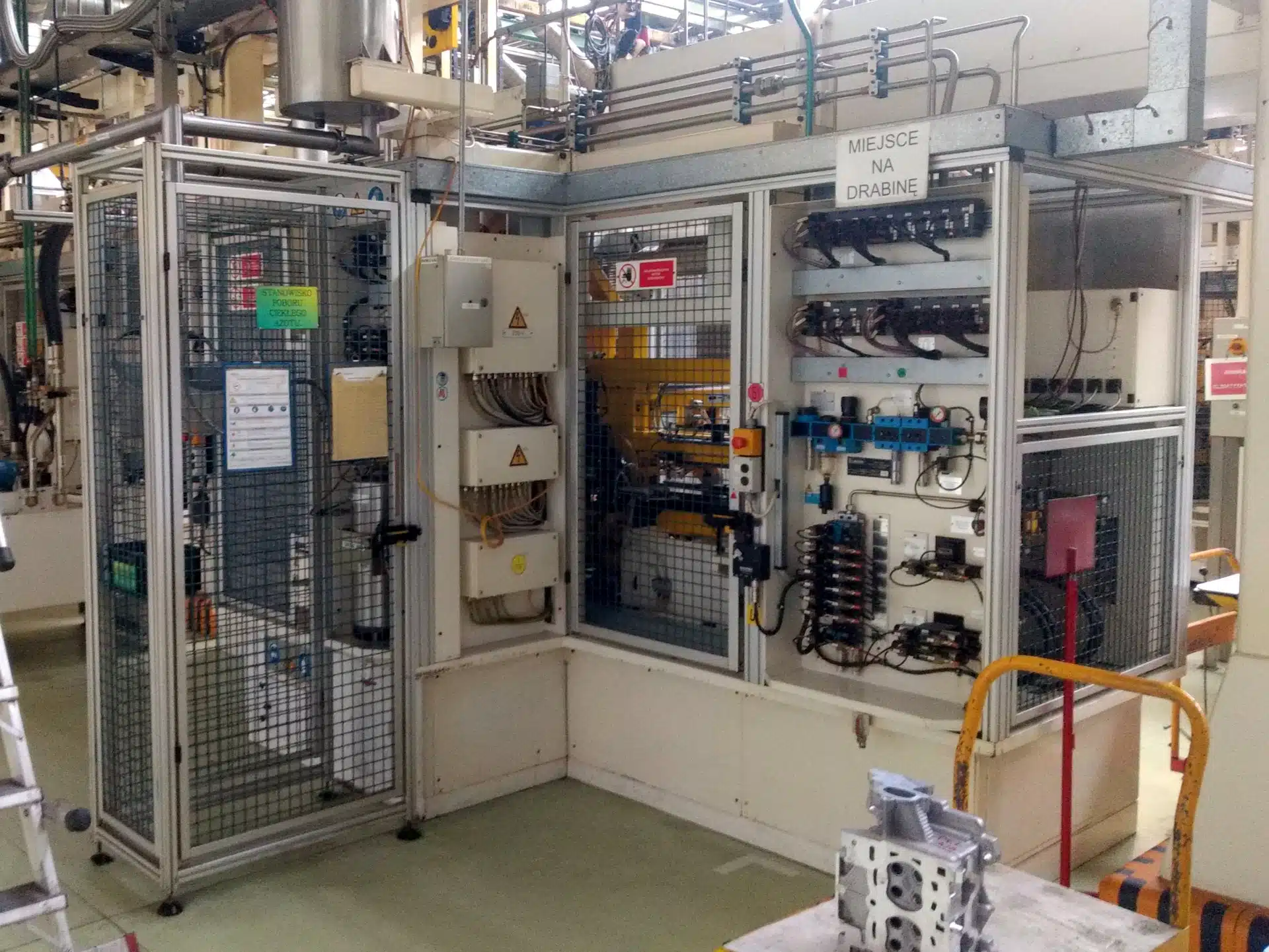

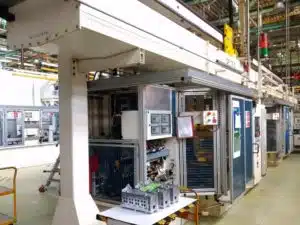

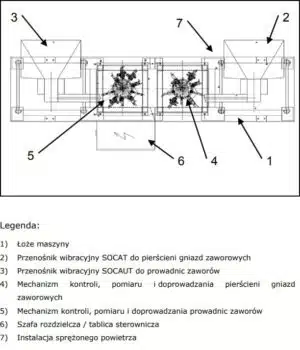

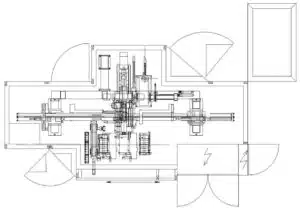

The ELWEMA valve seat ring injection machine was built in 2002 by the German company ELWEMA Werkzeug- und Maschinenbau GmbH. The purpose of the machine is to insert valve seat rings and valve guides into lower cylinder heads. The installation is equipped with, among others: a lubrication system with a WILLY VOGEL control unit, a SIEMENS Sinumerik 840D CNC control unit and a number of mechanisms necessary for the operation of the machine.

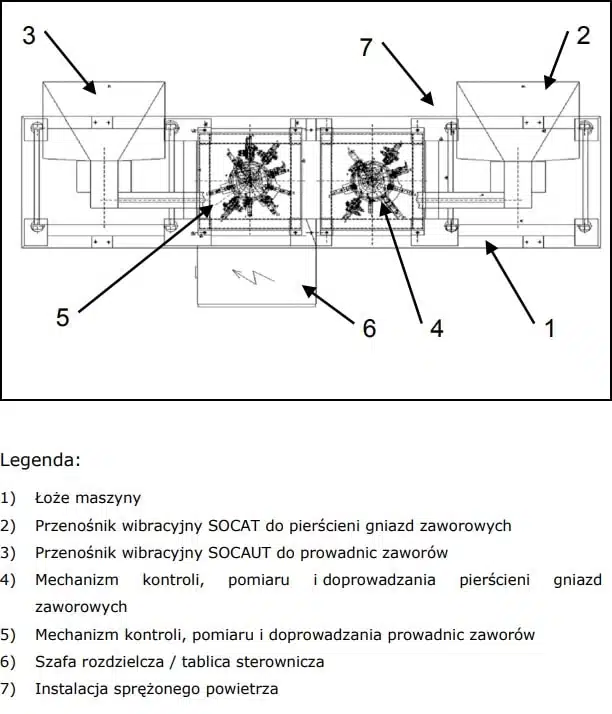

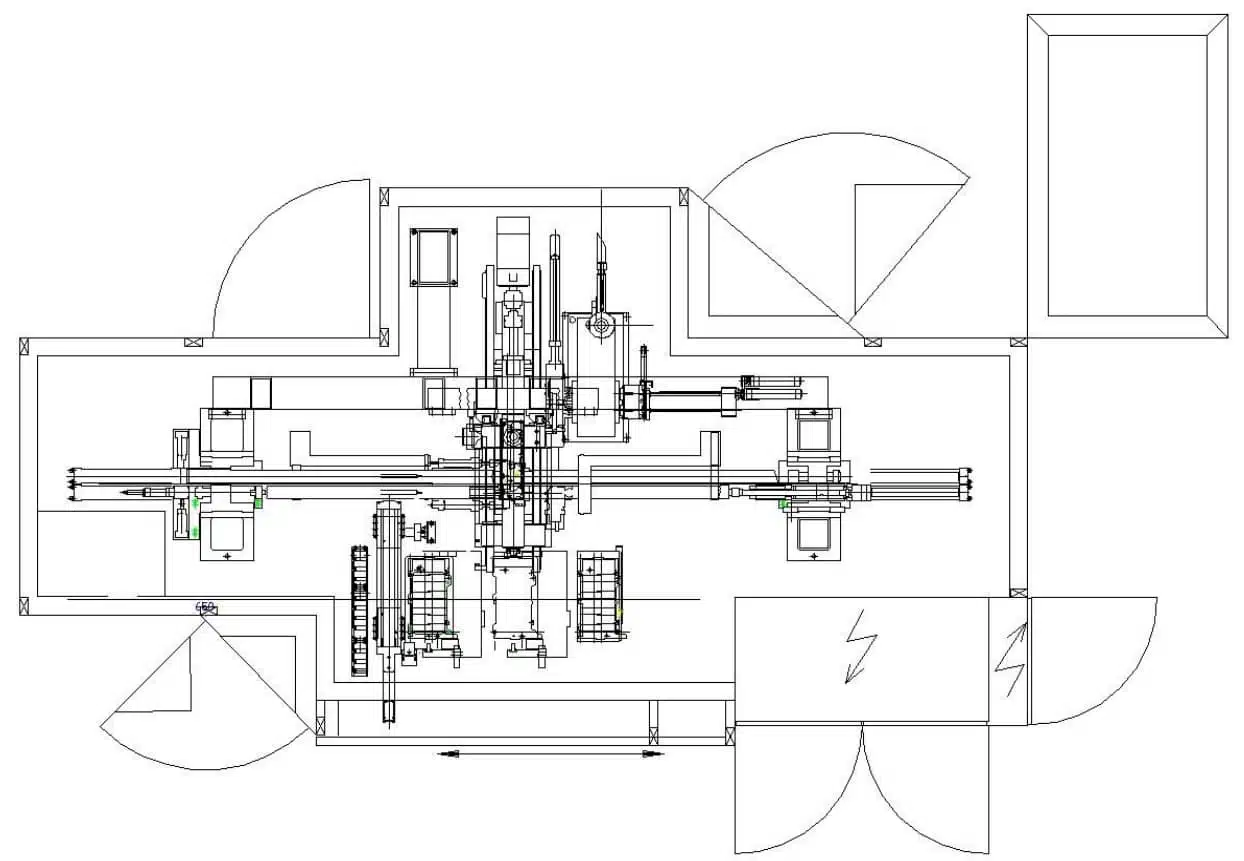

The RT 100-08-240 rotary table is mounted to the ELWEMA machine bed and consists of an arc-welded frame with steel supports, a connecting plate and an electromagnetically controlled rotary table with 10 positions. The valve seat rings, valve guides and take-up mechanisms on the connecting plate can be rotated by 36° (1/10 turn) with each actuation of the rotary table.

The injection of the valve seat rings and valve guide into one cylinder head at a time is carried out during a work cycle consisting of two processes. Process one is the simultaneous injection of two valve seat rings cooled in liquid nitrogen. Process two is the simultaneous injection of two valve guides at room temperature.

The cylinder head insertion and removal process can be performed in two ways – automatically or manually. The automatic process is carried out by means of a gantry lifting mechanism. The mechanism loads the cylinder head onto the left plate, which is responsible for lubrication, and removes it from the right plate in the unloading position. The manual process, on the other hand, is carried out by means of a hoist after the “automatic loading” mode has been deactivated by means of a selector switch.

Automatic feeding of the valve seat rings and valve guides to the injection punches is possible with the aid of the overlapping and centring mechanism and the parts feeding system to the container on the cylinder head gantry lift. With each loading and unloading, the gantry lifter fills the containers in the plant.

Technical specifications of the ELWEMA machine

- number of compartments / divisions of the rotary table: 10

- rotation angle of each compartment / division: 36 degrees

- loading height of valve seat rings and valve guides: 1050 mm

- working pressure: 0.5 Mpa

- power consumption: 11 kW

- working voltage: 380V

- frequency: 50 Hz

- machine dimensions (L x W x H): 4350 x 1800 x 2600 mm

- machine weight: 2500 kg

Equipment of the valve seat ring injection machine

- CNC control: SIEMENS Sinumerik 840D

- rotary table: RT 100-08-240

- lubrication system with control unit: WILLY VOGEL

- compressed air system: FESTO

- automatic marking equipment: MARKATOR MV15

- vibrating conveyor for valve seat rings: SOCAUT

- hydraulic system with GNG leakage control mechanism

- valve seat ring metering system

- manipulation mechanism for inserting and removing the valve seat rings

- valve guide handling mechanism

- valve seat ring handling mechanism

- tool positioning mechanism

- valve guide insertion punch replacement mechanism