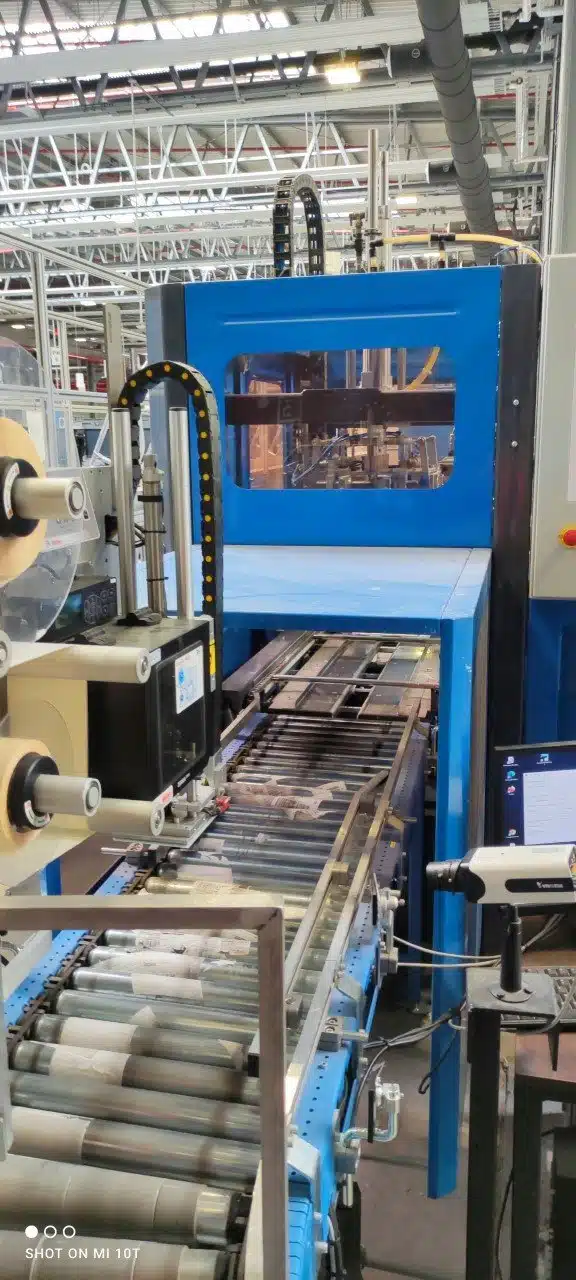

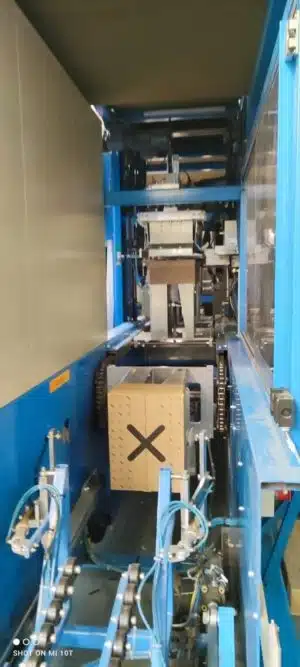

SAVOYE INTELIS packaging machine was built in 2016 in France. The machine is used for example in halls or warehouses, for the fully automatic packing of carton shipping boxes made of corrugated cardboard. All of the devices included in the packaging line are independent and built on the “plug and play” concept, which allows easy relocation and installation.

The SAVOYE INTELIS packaging line consists of the following devices:

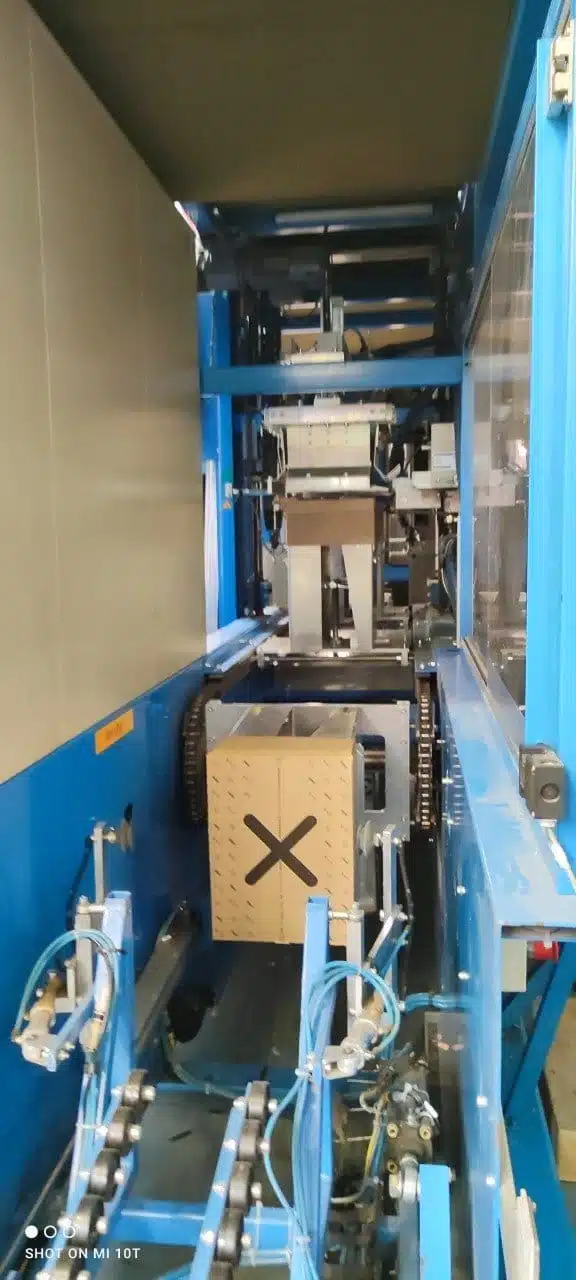

– case erecting machine: INTELIS F12

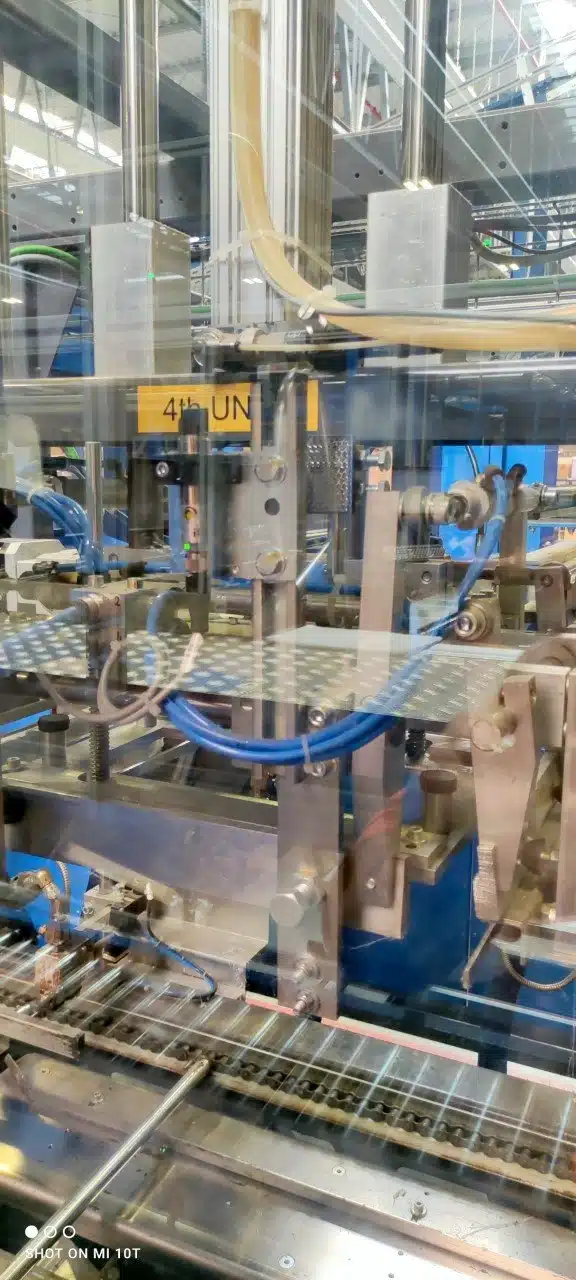

– shrink tunnel: INTELIS T18

– box lid placing machine: INTELIS C12

– glue dispenser: NORDSON PROBLUE

The packaging machine is equipped with intelligent conveyors which adjust to the load of the packages and the intensity of work, making the whole packing process smoother. The motors built directly into the rollers operate 100% electrically and thanks to their design and technology used, they save a considerable amount of energy. The ecological mode of the machine allows for recovery of braking energy of the conveyor rollers, which is then used to drive them further.

During the operation of the packaging machine, a cardboard shipping box goes through many stages, such as forming the walls of the corrugated board, heating the shrink film and closing the box and sticking a shipping label on it. During one hour the machine is able to handle and pack up to 840 boxes, with a maximum weight of 32 kg each.

Technical specifications of SAVOYE INTELIS packaging line

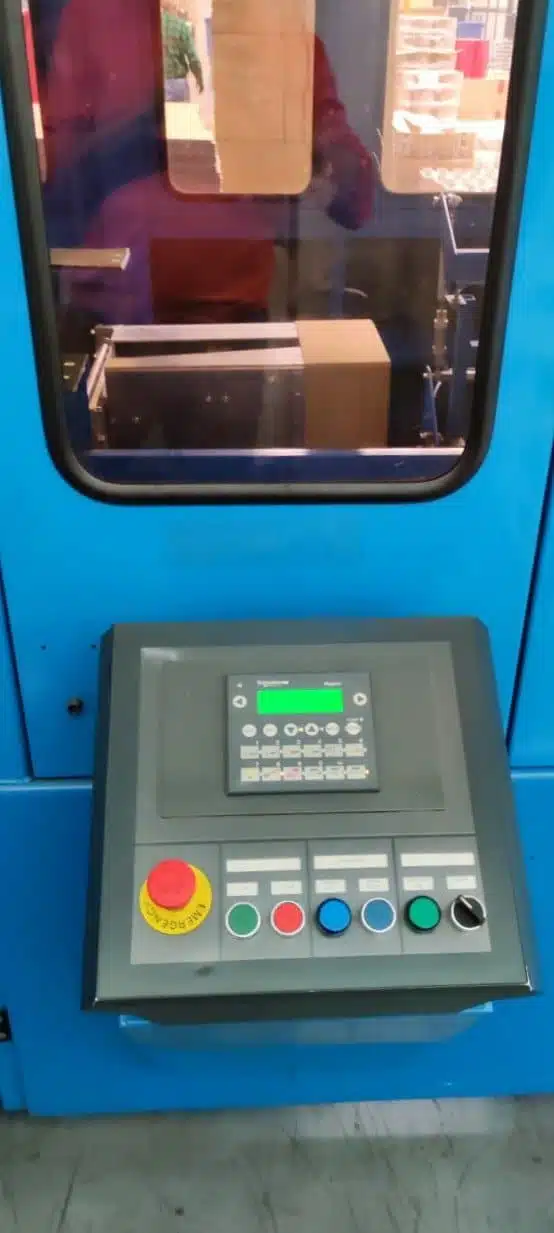

- PLC control: TSXP572634M

- number of packed boxes: 840 pcs/h

- minimum dimensions of the box: 300 x 200 x 110 mm

- maximum dimensions of the box: 600 x 400 x 430 mm

- maximum weight of the box: 32 kg

- power supply: 3 phase 400 V

- power: 5 kVA