ECKERT JANTAR plasma cutting machine was built in 2016 in Poland. The machine with a working table having a length of 6000 mm and a width of 2000 mm, is used for cutting sheet metal made of black steel, stainless steel, acid-resistant steel or aluminium, by using a plasma or oxygen torch. The plasma torch can cut workpieces with a thickness of up to 40 mm, while the oxygen torch can cut workpieces with a maximum thickness of 100 mm.

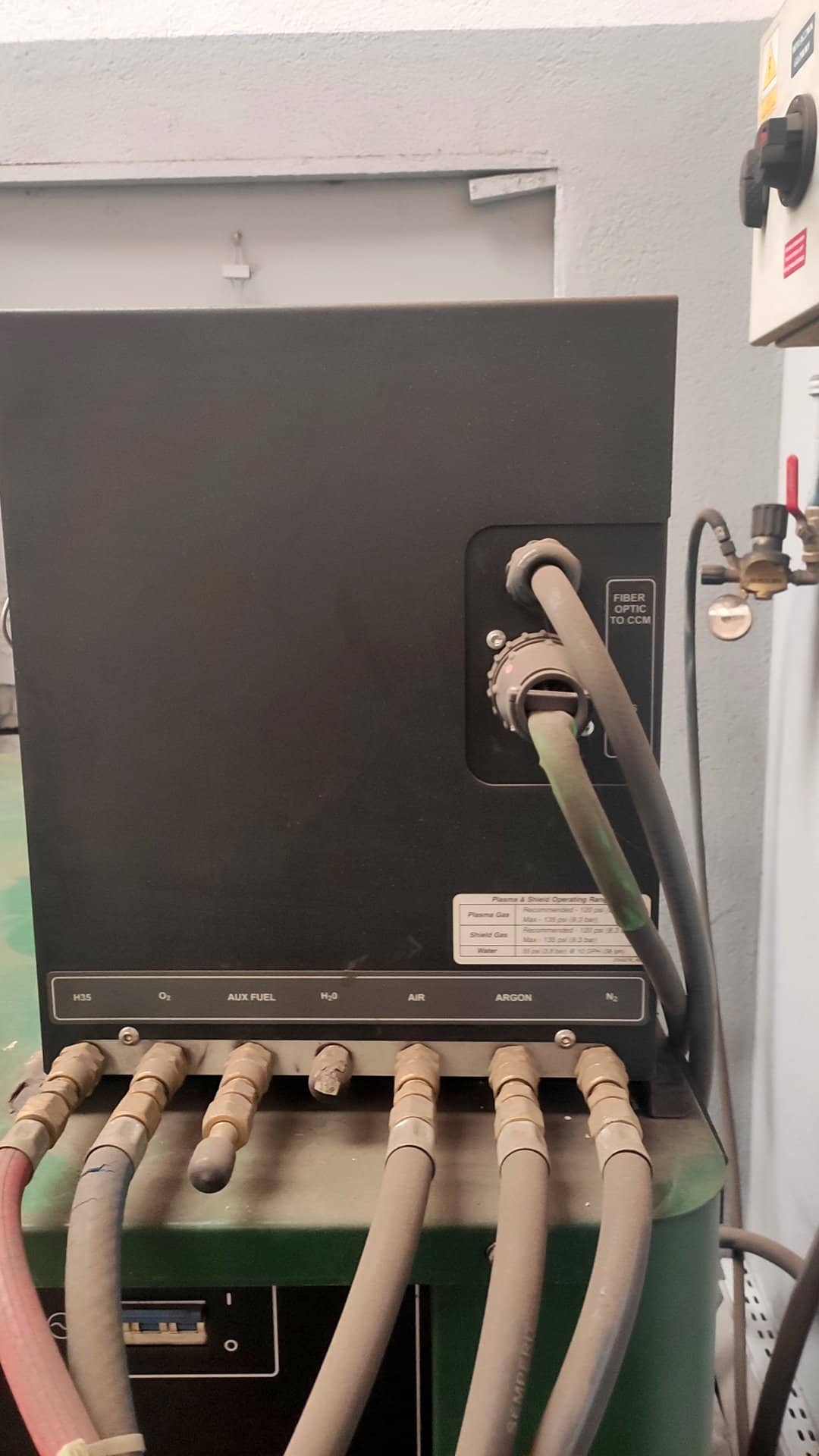

The plasma cutting machine has an open structure made of high-quality welded steel with an extraction table, giving the operator free access to the machine’s working table. Vibrations and dust generated during the cutting process are eliminated on an ongoing basis, ensuring high machining stability and high safety and comfort. The plasma cutting machine is also equipped with a wide range of equipment, including: a PFC-4 filtering unit with a capacity of 7000 m3/h with the option of heat recovery and automatic removal of contaminants, an ECS 872 CNC controller and a THERMAL DYNAMICS ULTRA-CUT 300 XT plasma generator.

Technical data of the ECKERT JANTAR plasma cutting machine

- working table dimensions (L x W): 6000 x 2000 mm

- height of the working table of the JANTAR machine : 740 mm

- cutting materials: black steel, stainless steel, acid resistant steel, aluminium

- maximum sheet thickness (plasma cutting): 40 mm

- maximum sheet thickness (oxygen cutting): 100 mm

- positioning speed: 25000 mm/min

- filter unit capacity: 7000 m3/h

- filter unit power: 7.5 kW

Equipment of the plasma cutting machine

- CNC control: ECS 872

- plasma source: THERMAL DYNAMICS ULTRA-CUT 300 XT

- remote arc starter: THERMAL DYNAMICS RAS 1000 XT

- extraction table

- filter unit: PFC-4

- plasma torch

- oxygen torch

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe