TRUMPF TruLaser 3030 laser cutting machine was built in 2012. The machine characterised by a stable steel structure equipped with the best components, is designed for cutting sheet metal made of stainless steel, mild steel and aluminium. Excellent quality and precision are guaranteed by the 3 kW CO2 laser beam, which cuts workpieces weighing up to 900 kg and with a thickness of 20 mm (mild steel), 12 mm (stainless steel) or 8 mm (aluminium).

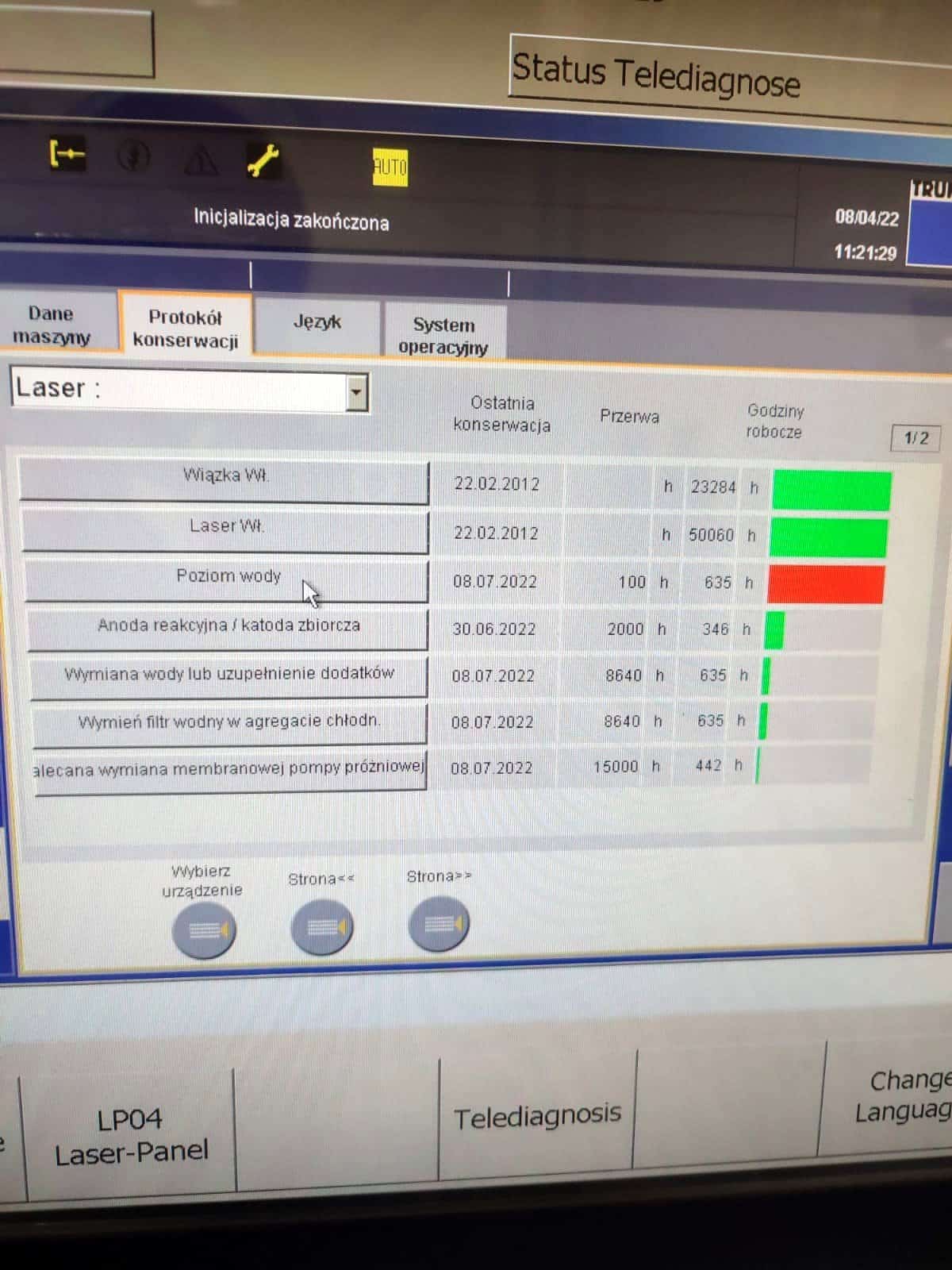

The TruLaser 3030 L20 laser cutting machine is offered with accessories, consisting of among others an intuitive SIEMENS SINUMERIK 840 SL CNC controller, a pallet exchange system and X,Y,Z axis servo motors. The laser went through regular maintenance – the last performed inspection took place in July 2022. The total weight of the machine is approximately 11000 kg.

Technical data of the TRUMPF TruLaser 3030 laser cutting machine

- laser power: 3 kW (3000 W)

- laser type: CO2

- wavelength: 10.6 μm

- working area in the X/Y/Z axis: 3000/1500/115 mm

- feed rate in the X/Y/Z axis: 3104/1580/122 mm

- positioning speed parallel to the axis: 60 m/min

- positioning speed with simultaneous operation of the X and Y axes drives: 140 m/min

- maximum sheet weight: 900 kg

- maximum workpiece thickness (mild steel): 20 mm

- maximum workpiece thickness (stainless steel): 12 mm

- maximum workpiece thickness (aluminium): 8 mm

- positioning deviation: 0.05 mm

- average compressed air consumption: 700 l/min

- connection power: 73 kVA

- switch-on time of the machine: 50060 h

- laser beam emission time: 23284 h

- coupled air connection: 6 bar

- nitrogen connection N2: 30 bar

- O2 oxygen connection: 20 bar

- power supply: 400 V; 50 Hz

- overall dimensions (L x W x H): 9300 x 4700 x 2200 mm

- weight of the TruLaser 3030 machine: approx. 11000 kg

Equipment of the laser cutting machine

- CNC controller: SIEMENS SINUMERIK 840 SL

- automatic pallet changer

- conveyor belt

- cutting head with 5″ lens (2 pcs.)

- APC

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe