CINCINNATI MILACRON ARROW 500 CNC vertical machining centre was built in 1999. A compact machine characterised by low space requirement, is designed for precision machining of workpieces weighing up to 350 kg. The robust construction of the milling machine ensures a high stability, and the high-quality components in it guarantee excellent milling results.

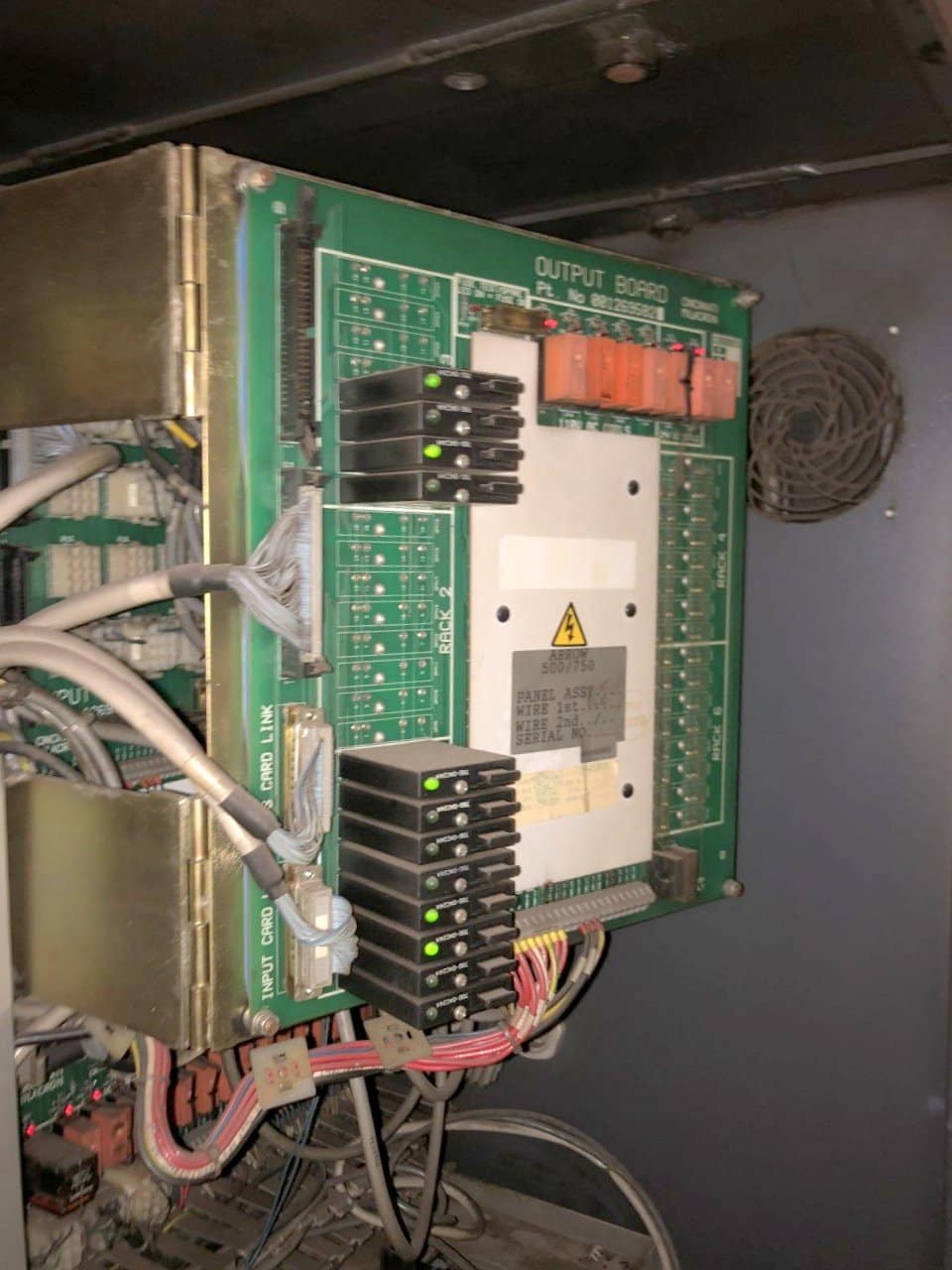

The vertical milling centre has a large work table with dimensions (L x W) of 520 x 700 mm with three T-slots and an extremely powerful spindle rotating at a maximum speed of 8000 rpm. The ACRAMATIC 2100E CNC controller, located on the machine body, allows for easy and fast programming and monitoring of the milling process. The total weight of the milling centre is 3050 kg.

Specification of the machining centre CINCINNATI MILACRON ARROW 500

- work table surface (L x W): 520 x 700 mm

- number of T-slots: 3

- feed rates in the X/Y/Z axis: 510/510/510 mm

- maximum workpiece weight: 350 kg

- minimum spindle speed: 60 rpm

- maximum spindle speed: 8000 rpm

- spindle power: 7.5 kW

- number of positions in tool magazine: 21

- maximum tool weight: 7 kg

- connection power: 16 kW

- overall dimensions (L x W x H): 2000 x 2650 x 2700 mm

- total weight of ARROW 500 machine: 3050 kg

Equipment of the CNC milling machine

- CNC controller: ACRAMATIC 2100E

- tool holder: SK40

- RS 232 port

- DTR – technical and propulsory documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe