HARTFORD VMC 1600SP CNC vertical machining centre manufactured in 2000 in Taiwan, is designed for precise machining of workpieces with a maximum weight of 1500 kg. The extremely reliable milling centre features a high-quality steel structure that guarantees great stability during machining. The milling process is performed on a large work table with dimensions (L x W) of 1700 x 750 mm in the X/Y/Z axes, with feed rates of 1600 (X axis), 800 (Y axis) and 660 mm (Z axis).

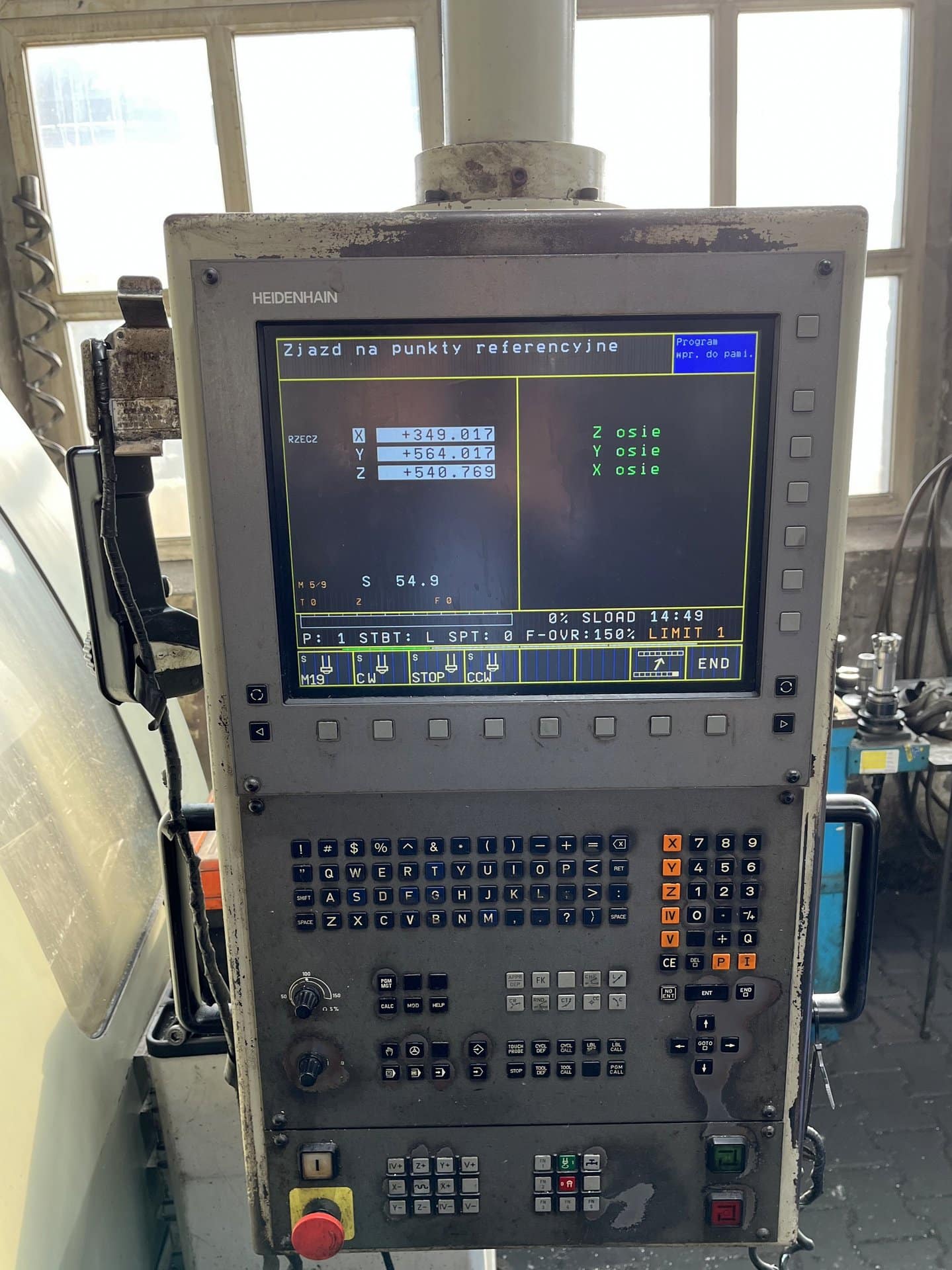

The VMC-1600SP machining centre is equipped with a tool magazine with a capacity of 20 pieces, HEIDENHAIN induction motors and a control panel located on the arm with a HEIDENHAIN TNC 426 CNC controller for, among others, programming operating modes. The total weight of the milling centre is 11300 kg.

Technical specifications of the HARTFORD VMC 1600SP CNC milling machine

- CNC controller: HEIDENHAIN TNC 426

- work table dimensions (L x W): 1700 x 750 mm

- feed rates in the X/Y/Z axis: 1600/800/660 mm

- maximum workpiece weight: 1500 kg

- maximum spindle speed: 4000 rpm

- minimum spindle speed: 40 rpm

- tool magazine capacity: 20 pcs.

- maximum cutting speed: 7000 mm/min

- minimum cutting speed: 1 mm/min

- induction motors: HEIDENHAIN

- main motor power: 20 kW

- total power requirement: 30 kVA

- air pressure: 6.5 kg/cm2 (92 psi)

- power supply: 3x 380/415 V; 50/60 Hz

- dimensions (L x W x H): 4350 x 3715 x 3155 mm

- VMC 1600 SP machine weight: 11300 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe