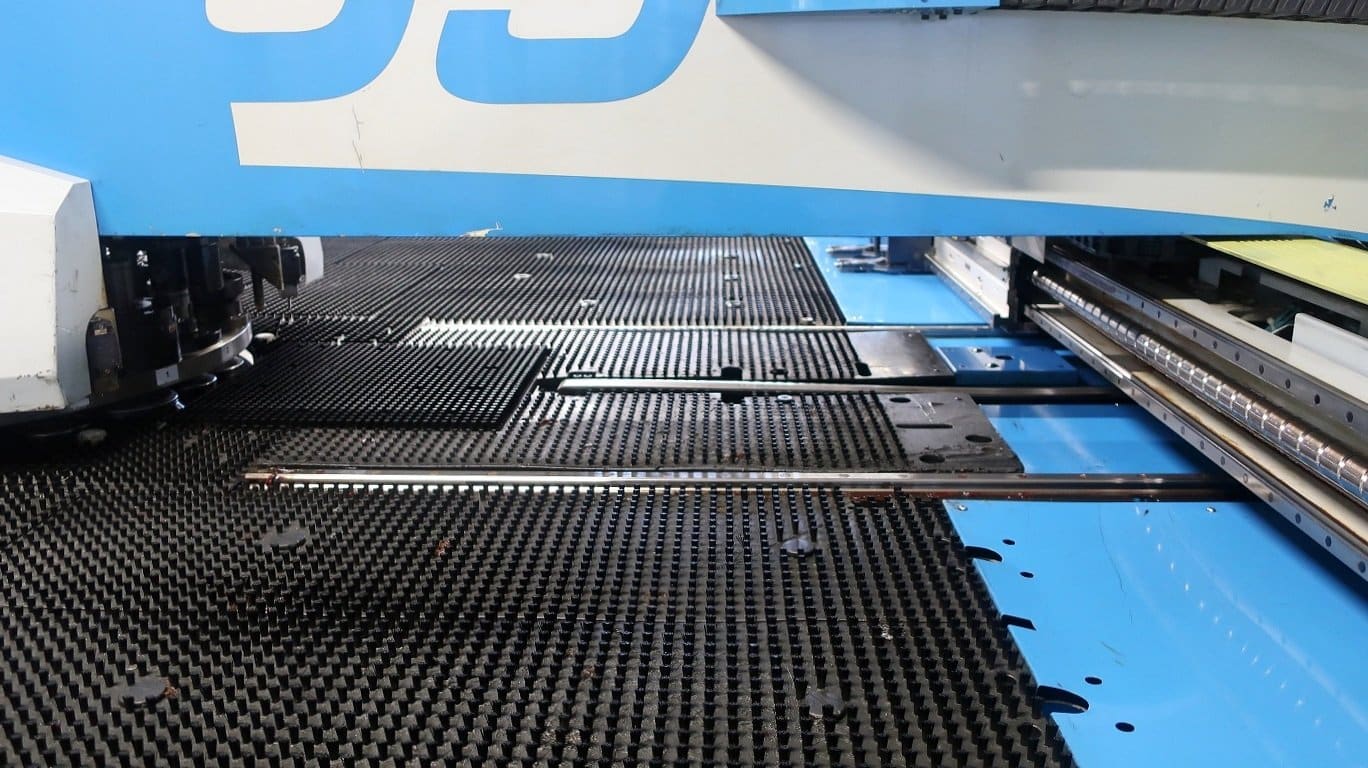

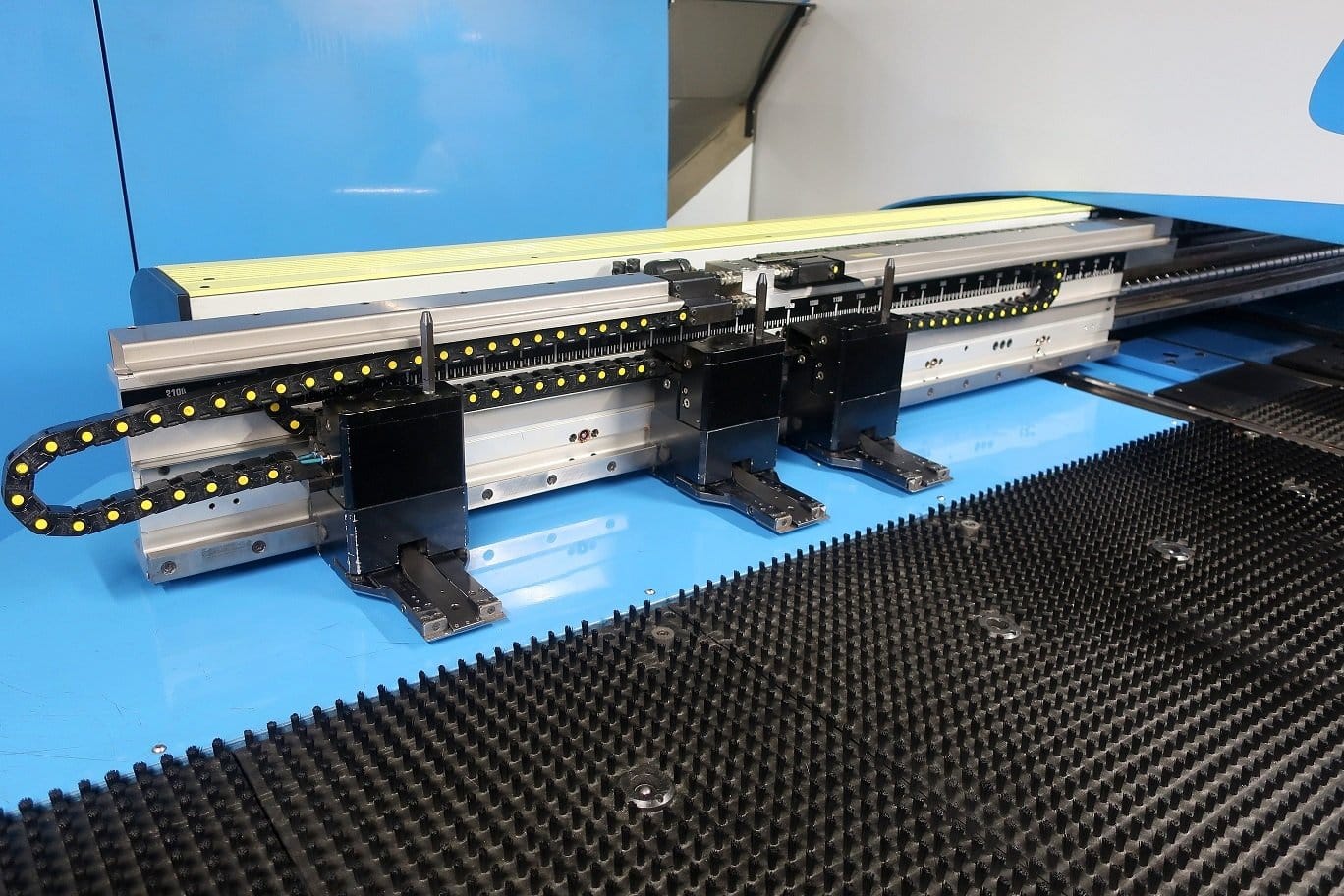

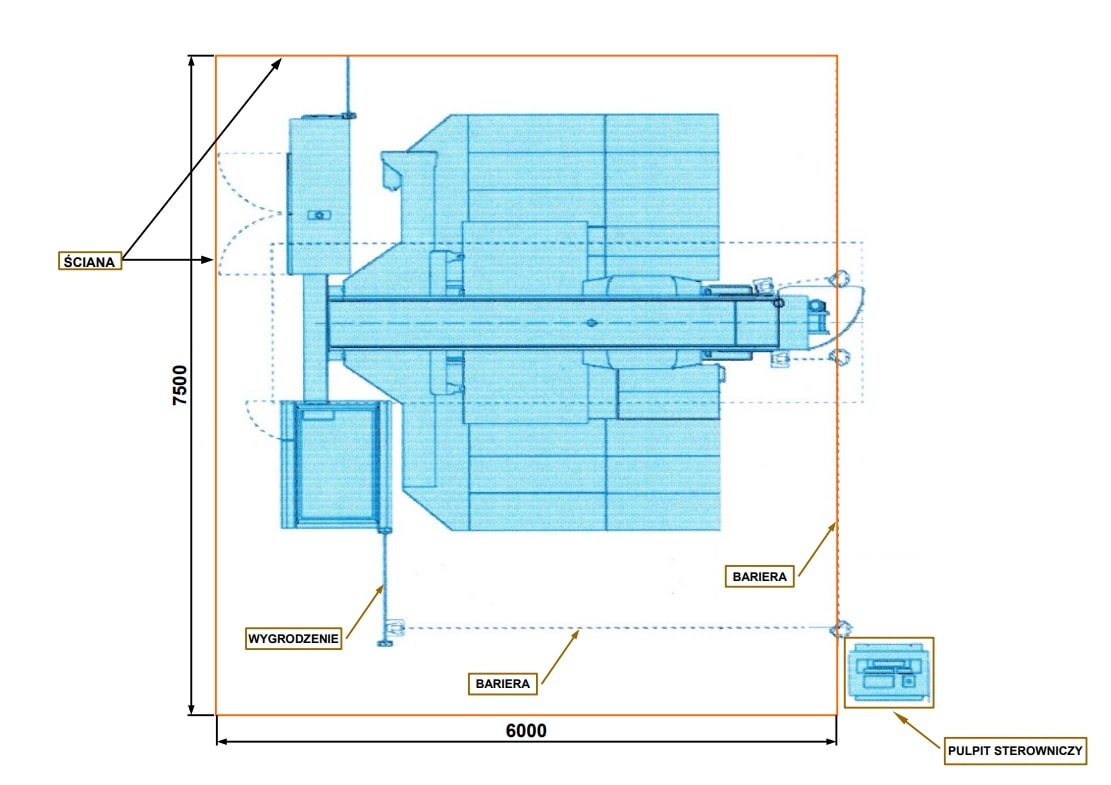

FINN POWER C5 punching machine built in 2008 in Finland, is used for processing of sheet metal with a maximum thickness of 8 mm. Punching of holes is performed with a press force of 30 tonnes using an extremely precise slider with servo-hydraulic stroke. An extensive range of equipment is offered with the machine, including two MultiTool heads with 10 and 24 stations, a FANUC 18i-PB CNC control for programming e.g. the slider stroke depth and a waste conveyor. The FINN POWER C5 F 12.44 punching machine weighs 13000 kg.

Technical specifications of the FINN POWER C5 punching machine

- maximum press force: 30 t (300 kN)

- feed rates in the X/Y axis: 2584/1317 mm

- speed of feeds in the X/Y axis: 90/60 m/min

- maximum transverse speed: 108 m/min

- maximum sheet thickness: 8 mm

- maximum sheet weight: 200 kg

- maximum workpiece dimensions (L x W): 2530 x 1270 mm

- minimum workpiece dimensions (L x W): 300 x 100 mm

- stroke rate (hole spacing: 1 mm): 1100/min

- stroke rate (hole spacing: 25 mm): 420/min

- stroke rate (hole spacing: 250 mm): 150/min

- marking speed: 3000/min

- maximum stamp diameter: 89 mm

- revolver speed: 23.8 rpm

- maximum tool rotation: 166 rpm

- tool change time: 1-3 s

- stroke of slider: servo-hydraulic

- numerically controlled stroke depth

- programmable stroke length and slider speed

- operating hours: 44529 h

- oil tank capacity: 400 l

- maximum operating pressure: 285 bar

- maximum compressed air consumption: 5 Nl/s

- average energy consumption: 13 kW

- weight of the C5 machine: 13000 kg

Equipment of the punching machine

- CNC control: FANUC 18i-PB

- turret with 20 stations (including 8 indexable stations)

- MultiTool head with 24 stations

- MultiTool head with 10 stations

- PASS and MATE tooling system

- waste conveyor

- pneumatic clamps (2 pcs)

- RS 232 port

- Ethernet port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe