TRUMPF TRUMATIC 500 ROTATION punching machine was manufactured in Germany in 1993. The machine with a stable and rigid construction guarantees high productivity and precision when processing sheet metal with a maximum thickness of 6 mm. Hole punching is performed with a force of 22 tonnes with tools that can be smoothly rotated in a range of 360° by equipping the tool station with a ROTATION drive.

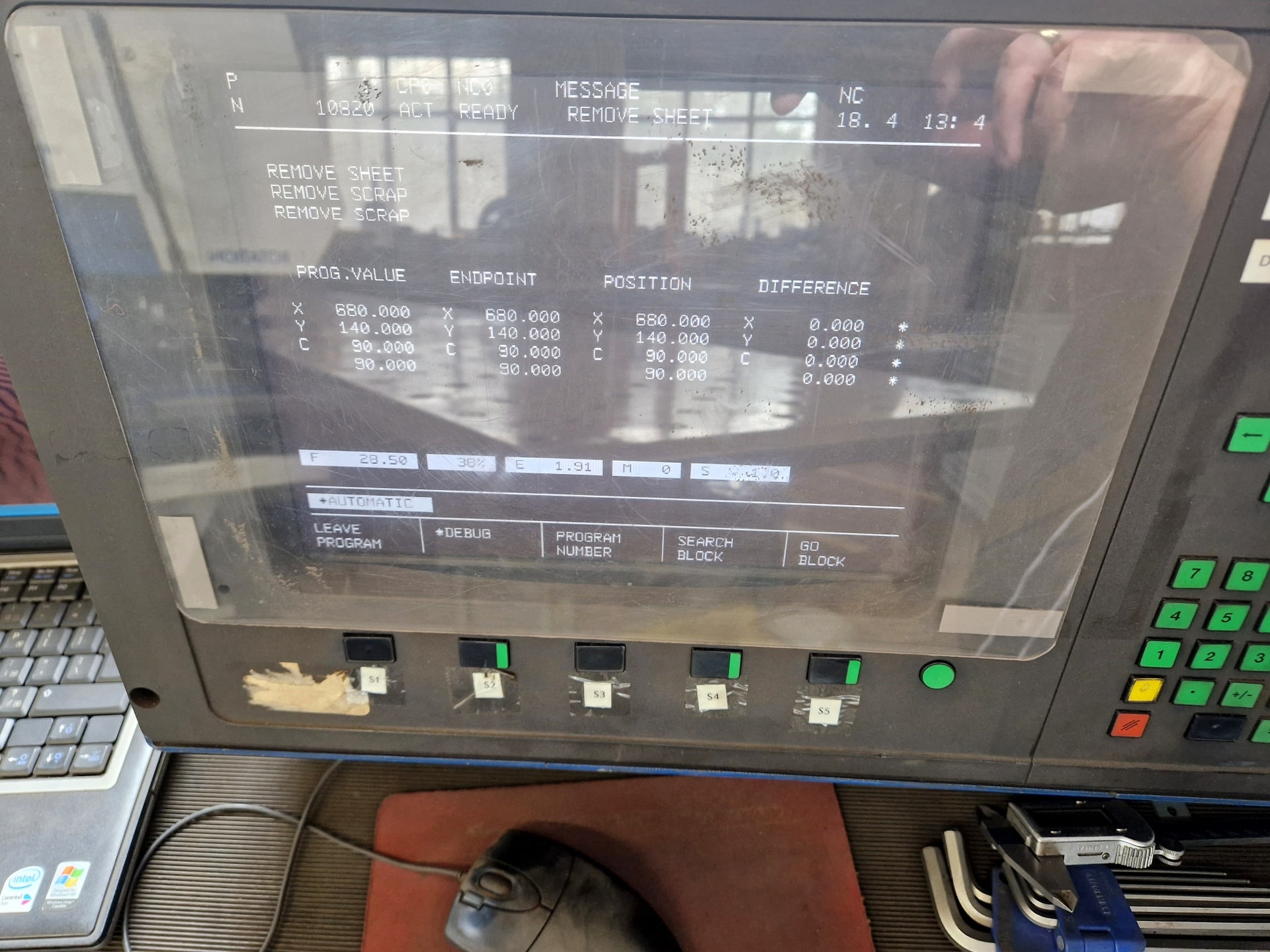

The TRUMPF TRUMATIC 500 R punching machine is offered with a comprehensive range of equipment including, among others, a set of approx. 150 punching tools (punches, dies, adapters and peelers), CAD/CAM software with NESTING function for creating machining programmes, and a BOSCH TRUMAGRAPH CNC control. The total weight of the machine is 11050 kg.

Technical specifications of the TRUMPF TRUMATIC 500 ROTATION punching machine

- maximum press force: 22 t (220 kN)

- maximum sheet thickness: 6 mm

- feed rates in X/Y axis: 2500/1250 mm

- working pressure: 6 bar

- power supply: 380 V; 50 Hz

- dimensions (L x W x H): 6400 x 5800 x 2100 mm

- TRUMATIC 500 ROTATION machine weight: 11050 kg

Equipment of the punching machine

- CNC controller: BOSCH TRUMAGRAPH

- CAD/CAM software with NESTING function

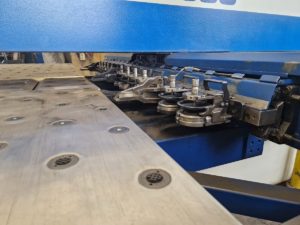

- ROTATION drive for stepless tool rotation in the tool head

- set of approx. 150 punching tools (dies, punches, adapters and nippers)

- QuickSet system for manual tool assembly

- tool cassettes (18 tools)

- PC computer

- diagonal and flat punch tool grinding device

- DTR – technical and propulsory documentation

All oils, filters and batteries were replaced in the machine. During its use, it has undergone regular technical inspections and is in very good condition.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe