MAZAK VTC 20C milling centre was manufactured in 1997 in the UK. The machine designed for precise and dynamic machining of workpieces with a maximum weight of 1000 kg has a high quality steel construction, which ensures rigidity and stability during milling. Inside the milling machine is a large work table with a length of 2000 mm and a width of 510 mm, and a reliable spindle that rotates at a maximum speed of 7000 rpm.

The VTC 20 C machining centre processes workpieces in three axes with feeds of 1660 mm (X axis), 510 mm (Y axis) and 510 mm (Z axis). The installed MAZATROL M PLUS CNC control allows full use of all the machine’s capabilities. The VTC 20-C vertical machining centre weighs 7320 kg.

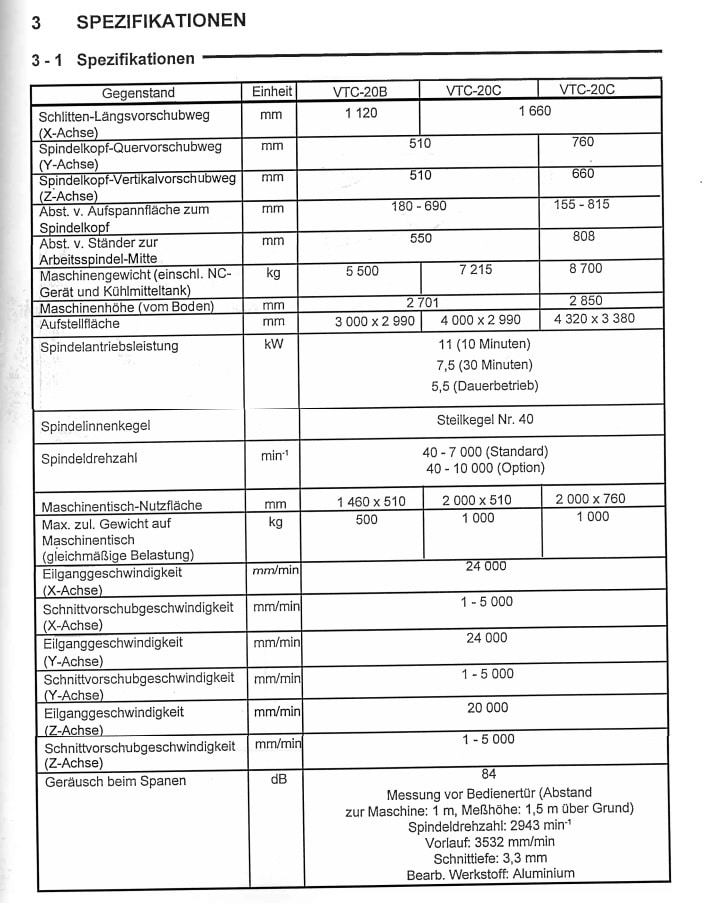

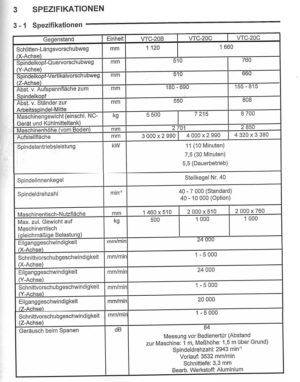

Technical data of the MAZAK VTC 20C milling centre

- CNC controller: MAZATROL M PLUS

- work table dimensions (L x W): 2000 x 510 mm

- feed rates in the X/Y/Z axis: 1660/510/510 mm

- rapid traverse in the X/Y/Z axis: 24000/24000/20000 mm/min

- cutting speed in the X/Y/Z axis: 1-5000 mm/min

- maximum workpiece weight: 1000 kg

- maximum spindle speed: 7000 rpm

- minimum spindle speed: 40 rpm

- tool magazine capacity: 2x 24 pcs. (48 tools in total)

- spindle drive power (10 min/30 min/constant operation): 11/7.5/5.5 kW

- spindle taper: ISO 40

- distance of clamping surface to spindle head: 180-690 mm

- distance of stand to work spindle centre: 550 mm

- machine height: 2701 mm

- VTC-20C machine weight with coolant tank: 7320 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe