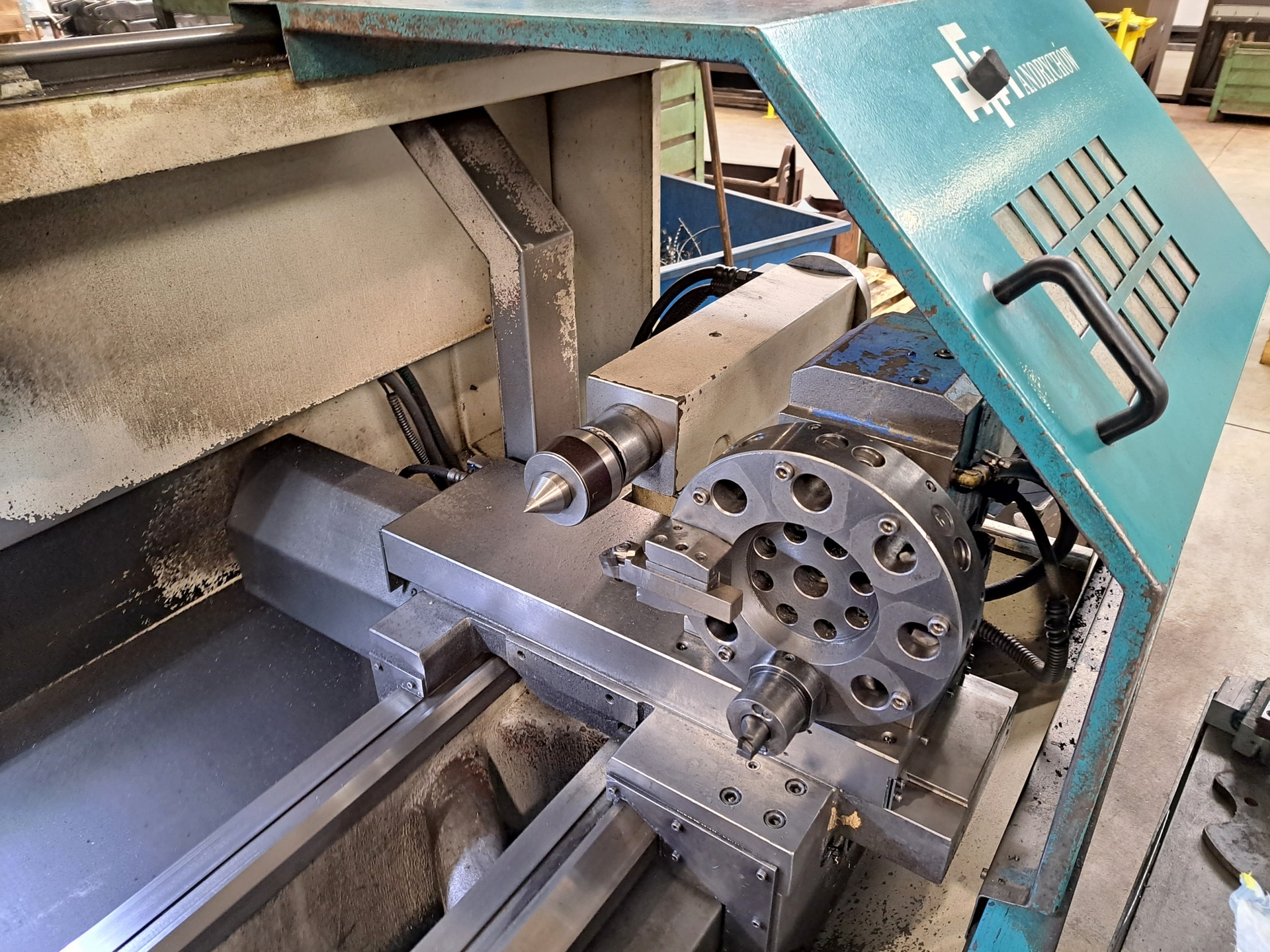

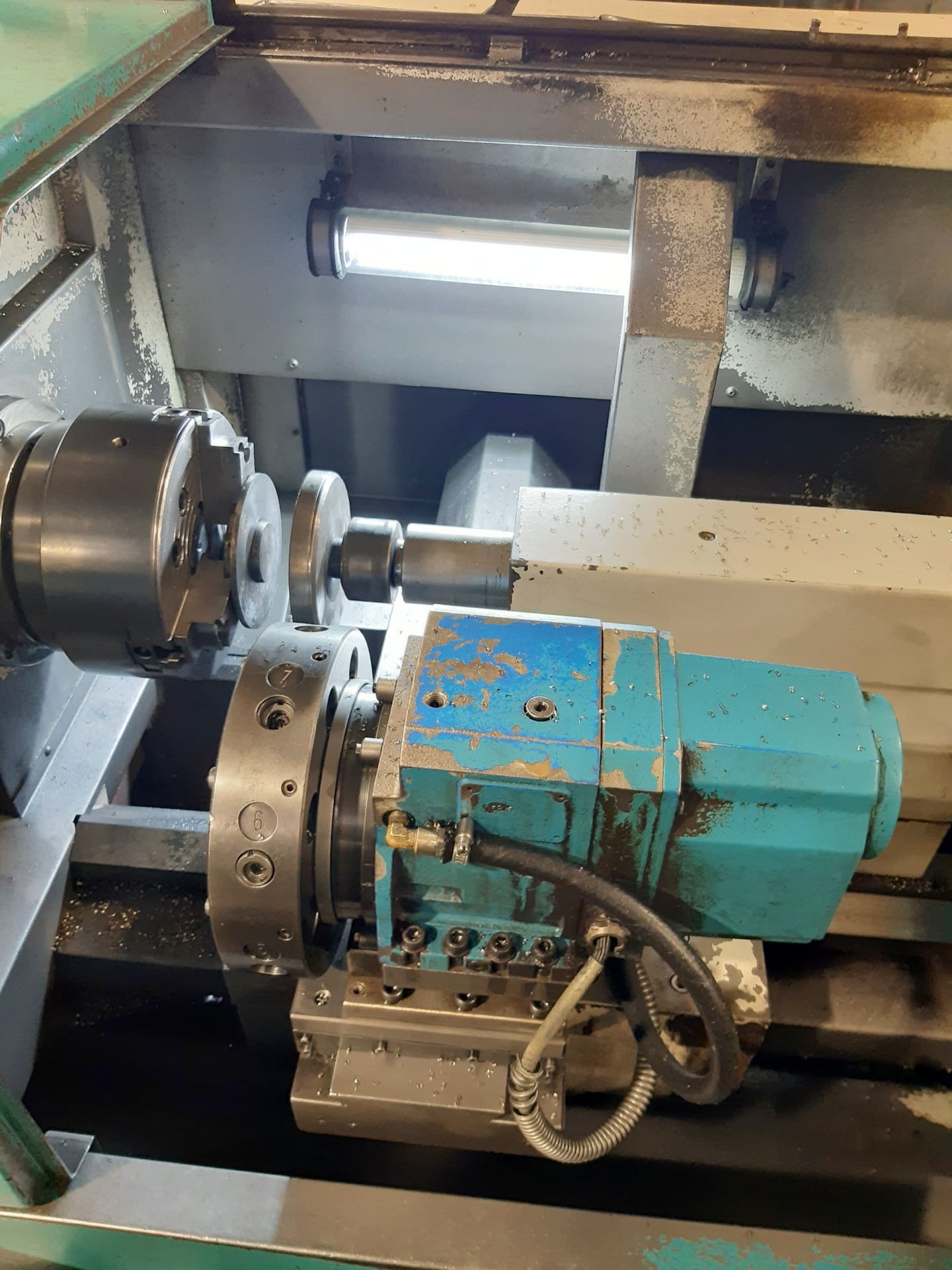

AFM TUG 56 MN MARYNA CNC lathe manufactured by the Polish factory AFM Andrychów in 2007 is designed to perform a wide range of workpiece machining mounted in tusk or chuck. Workpieces undergoing such operations as drilling or threading can have a maximum diameter of 300 mm (turning in the tusk) or 560 mm (turning in the chuck) and weigh up to 250 kg. The universal lathe is characterised by its sturdy, high-quality raw material construction with a bed supported on two box-shaped bases equipped with hardened guideways.

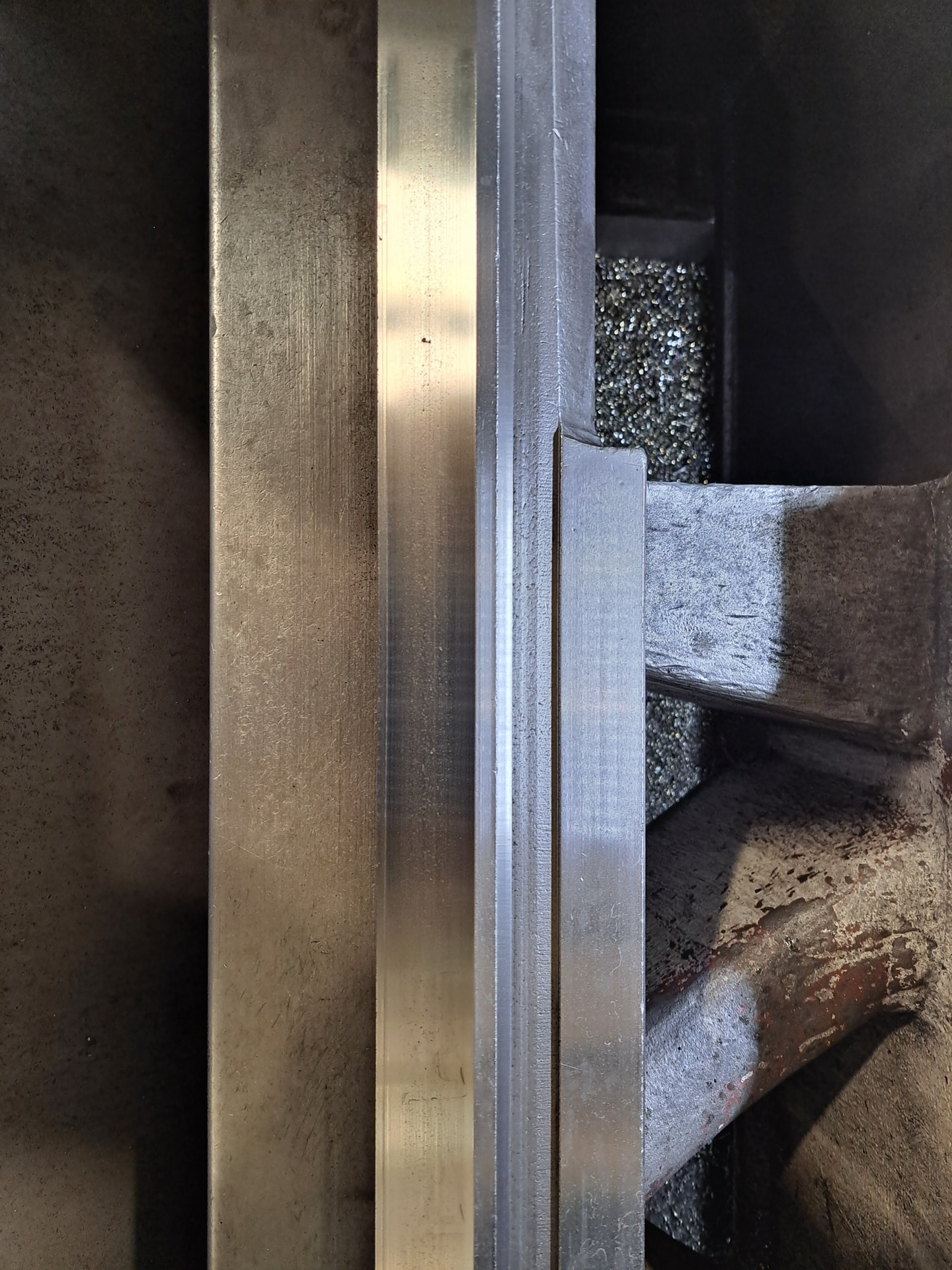

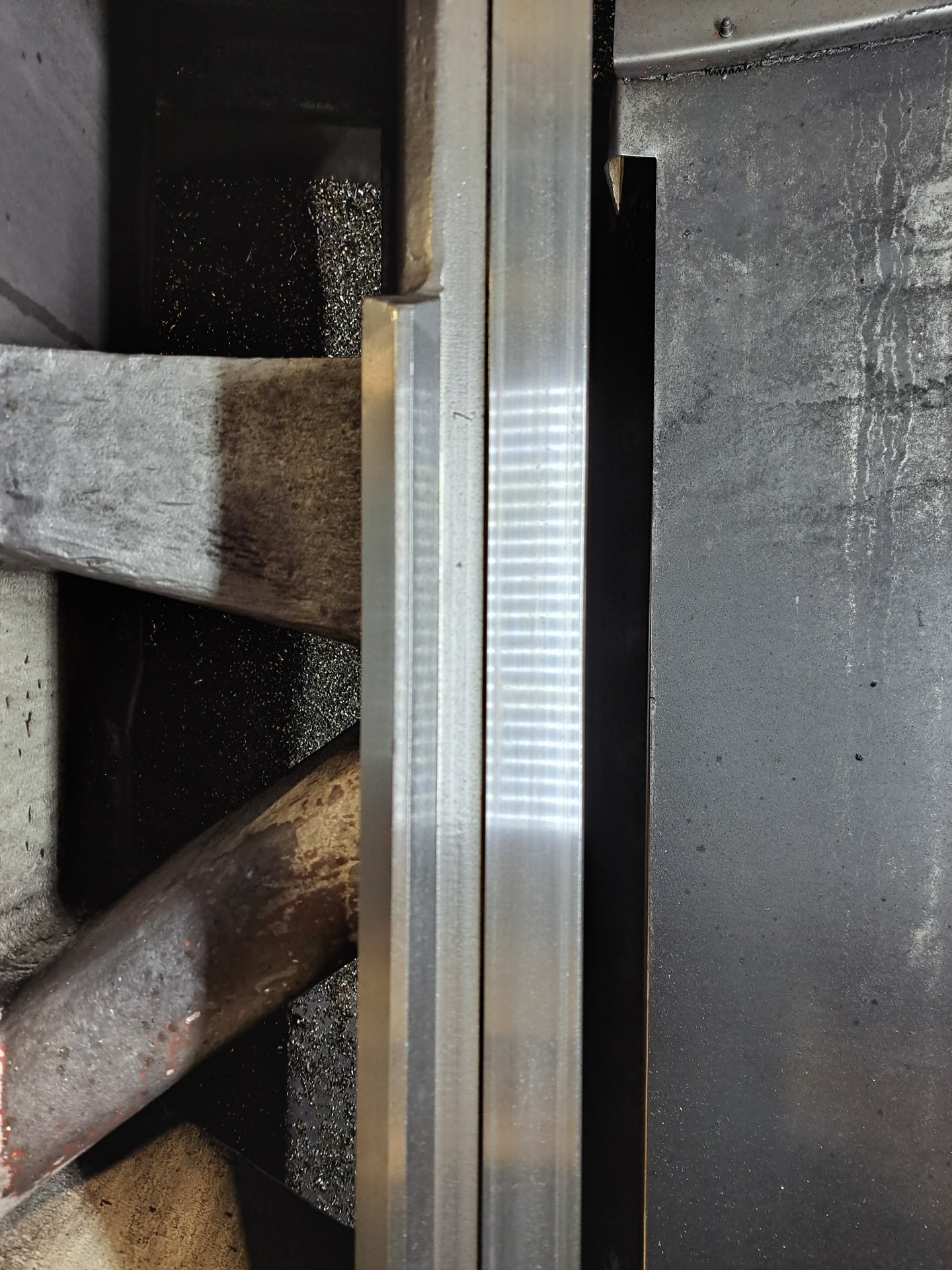

The slides of the X and Z axes are positioned with a high degree of accuracy by ballscrew gears driven by AC motors with electronic speed controllers. A high-frequency hardened prismatic and flat guideway is responsible for the longitudinal slide travel of the X axis, while the movement of the Z axis transverse slide takes place on a dovetail prismatic guideway. The movement of the machine tailstock with 180 mm long extension quills and Morse 5 internal taper also runs on a prismatic and flat guideway. The tailstock is fixed on the bed by two shanks clamped by bolts and nuts with a spanner.

Economical roughing and finishing operations using tools with carbide or ceramic inserts are guaranteed by a reliable spindle driven by a two-stage planetary gearbox with flange motor. The 9 kW spindle allows stepless speed adjustment in the range from 5 to 3000 rpm. The TUG56MN lathe’s equipment includes among others a cross slide, a FANUC Series 0i Mate-TC CNC control and a fixed guard to protect against chip splatter and coolant. The total weight of the machine is 2500 kg.

Technical specifications of the AFM TUG 56 MN MARYNA universal lathe

- feed rates in the X/Z axis: 1000/270 mm

- rapid traverse in the X/Z axis: 6/8 m/min

- maximum workpiece diameter (above bed guideways): 560 mm

- maximum workpiece diameter (above cross slide): 300 mm

- maximum workpiece length (in tusk): 925 mm

- maximum spindle speed: 3000 rpm

- minimum spindle speed: 5 rpm

- spindle power: 9 kW

- spindle passage: 75 mm

- spindle cylindrical end: ø 140 mm

- spindle torque: 105 Nm

- tusk spacing: 1000 mm

- tusk lift: 276 mm

- tailstock quill diameter: 75 mm

- tailstock quill extension: 180 mm

- tailstock quill taper: Morse 5

- lubrication system tank capacity: 2 dcm3

- lubrication system pressure: 0.25 MPa

- cooling system tank capacity: 65 dm3

- cooling system pump capacity: 20 dm3/min

- motor power of cooling system electropump 3 COA2-12: 0.09 kW

- motor speed of cooling system electropump 3 COA2-12: 2800 (50 Hz)/3300 (60 Hz) rpm

- cooling system pressure: 40 kPA

- hydraulic system tank capacity: 40 dm3

- hydraulic pump capacity: 12 (16) l/min

- hydraulic drive motor power: 1.5 kW

- hydraulic drive motor speed: 1420 rpm

- dimensions (L x W x H): 3500 x 1590 x 1566 mm

- weight of the TUG 56 MN MARYNA machine: 2500 kg

Equipment of the CNC lathe

- CNC control: FANUC Series 0i Mate-TC

- rear guard fixed over entire bed length

- front guard to protect against chips

- screw and pin shaft cover

- levelling plates

- cooling system with electropump

- electrical installation with lighting lamp

- DTR – Technical and Operating Documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe