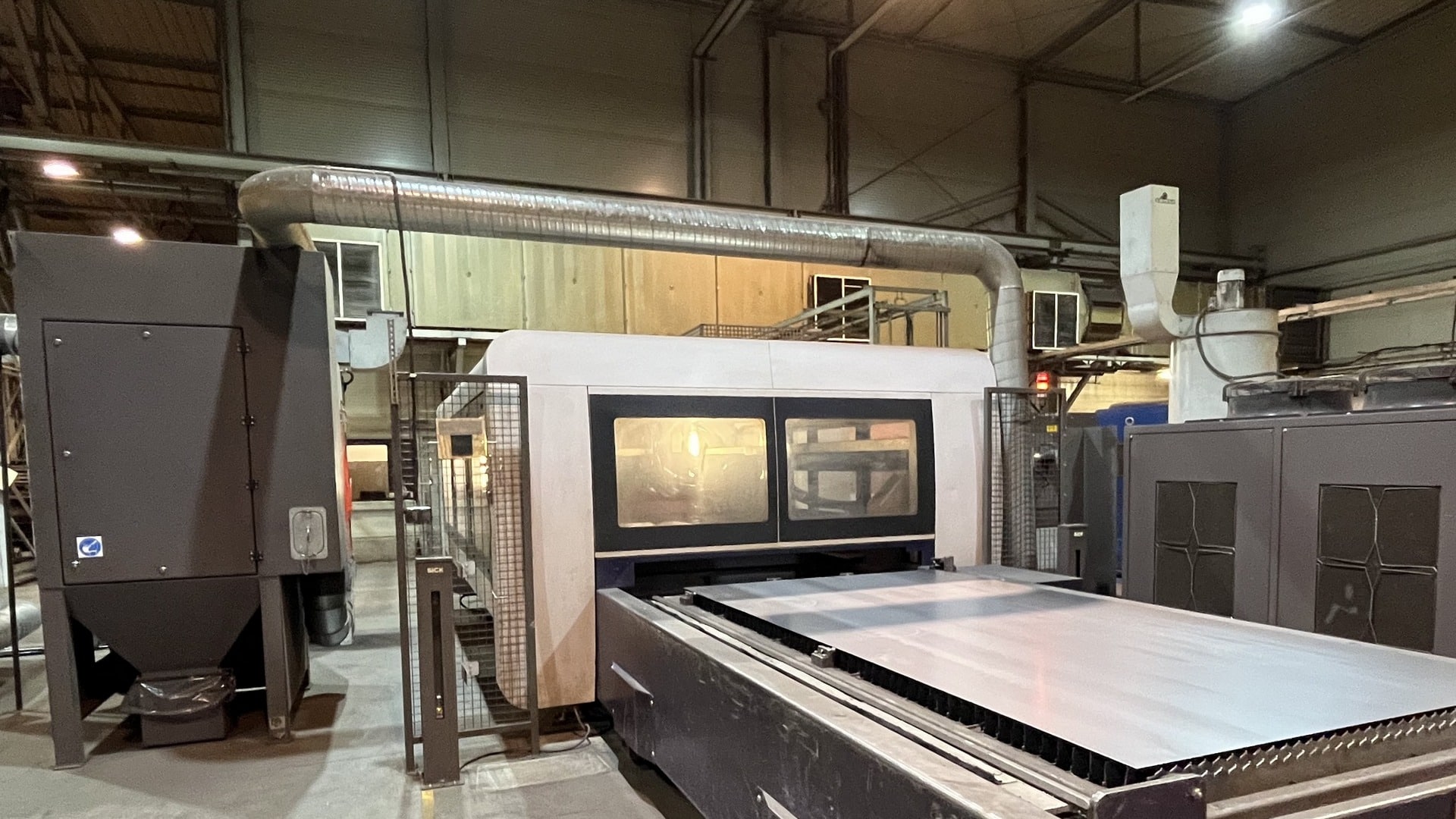

BYSTRONIC BySprint Pro 3015 laser cutting machine built in 2011 in Switzerland is used for cutting and engraving sheets of plain steel, stainless steel and aluminium. The machine, distinguished by its modern components and excellent precision, guarantees the achivement of very smooth and even edges along the entire length of the workpiece. The sheet metal is cut on a large steel work table with a length of 3000 mm and a width of 1500 mm, using a stable laser beam with a power of up to 4.4 kW. All of the machine’s axes (X,Y,Z) are equipped with reliable servo motors, which guarantee high axis acceleration, high dynamics and a long service life. The BYSTRONIC laser cutting machine is also equipped with, among others, a dust extraction unit, an automatic pallet changing system and the user-friendly BYSTRONIC ByVision CNC control. The total weight of the machine is 13000 kg.

Technical data of BYSTRONIC BySprint Pro 3015 laser

- laser beam power: 4.4 kW (4400 W)

- feed rates in the X/Y/Z axis: 3048/1524/70 mm

- work table dimensions (L x W): 3000 x 1500 mm

- maximum workpiece thickness (plain steel): 20 mm

- maximum workpiece thickness (stainless steel): 12 mm

- maximum workpiece thickness (aluminium): 8 mm

- maximum sheet weight: 750 kg

- maximum simultaneous positioning speed of the X/Y axis: 140 m/min

- maximum parallel positioning speed of the X/Y axis: 100 m/min

- positioning accuracy: ± 0.1 mm

- repeatability of positioning: ± 0.05 mm

- edge detection accuracy: ± 0.5 mm

- wavelength: 10.6 μm

- laser type: CO2

- working hours: 61825 h

- resonator operating time: 84792 h

- total power requirement: 40 kW

- dimensions (L x W x H): 10400 x 6500 x 2450 mm

- weight of laser source: 1700 kg

- weight of machine: 13000 kg

Equipment of the laser cutting machine By Sprint Pro 3015

- CNC control: BYSTRONIC ByVision

- laser source: BYSTRONIC ByLaser 4400

- dust extraction unit

- cooling unit: EF COOLING

- servo motors of the X,Y,Z axes

- automatic pallet changing system

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe