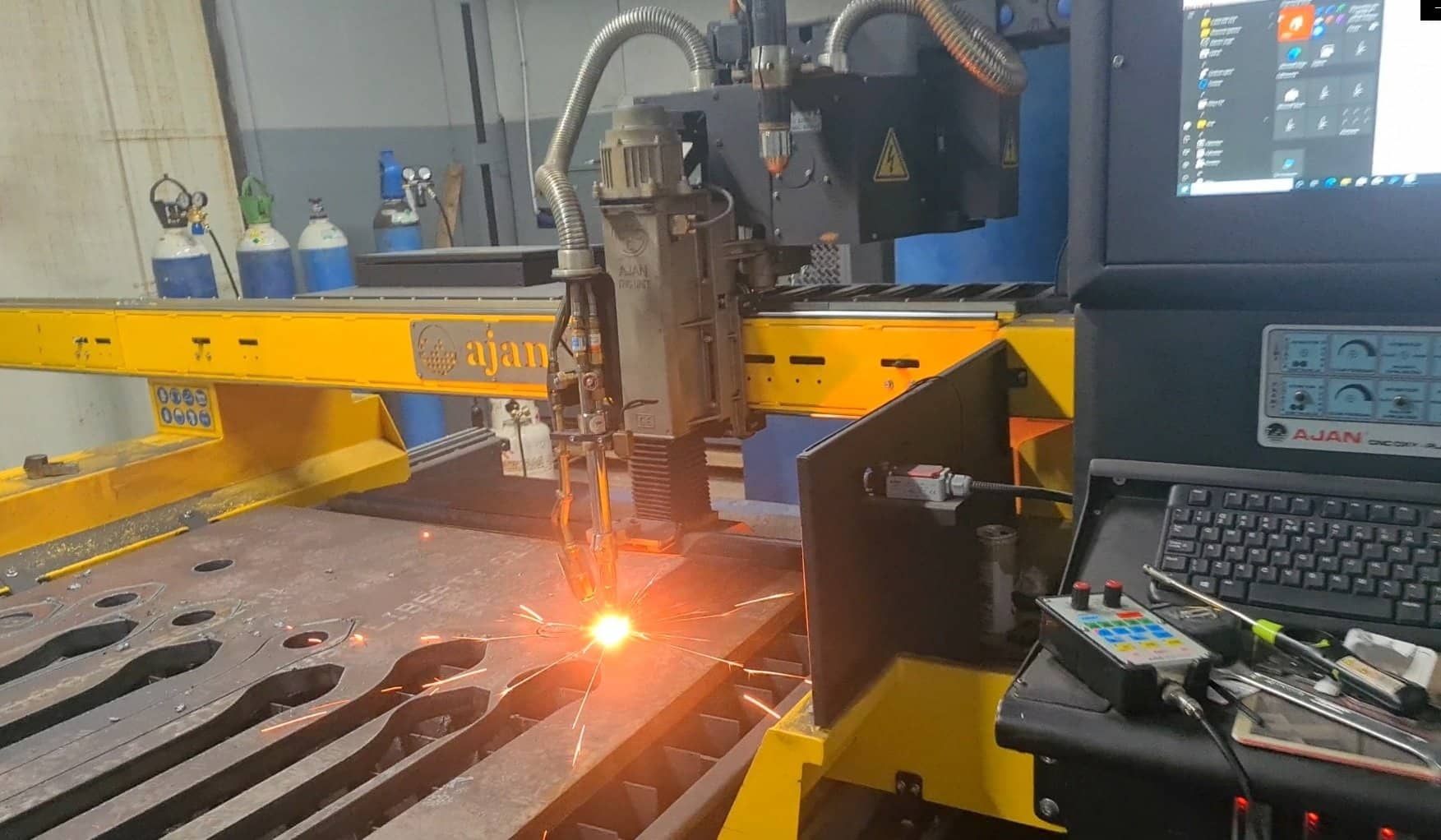

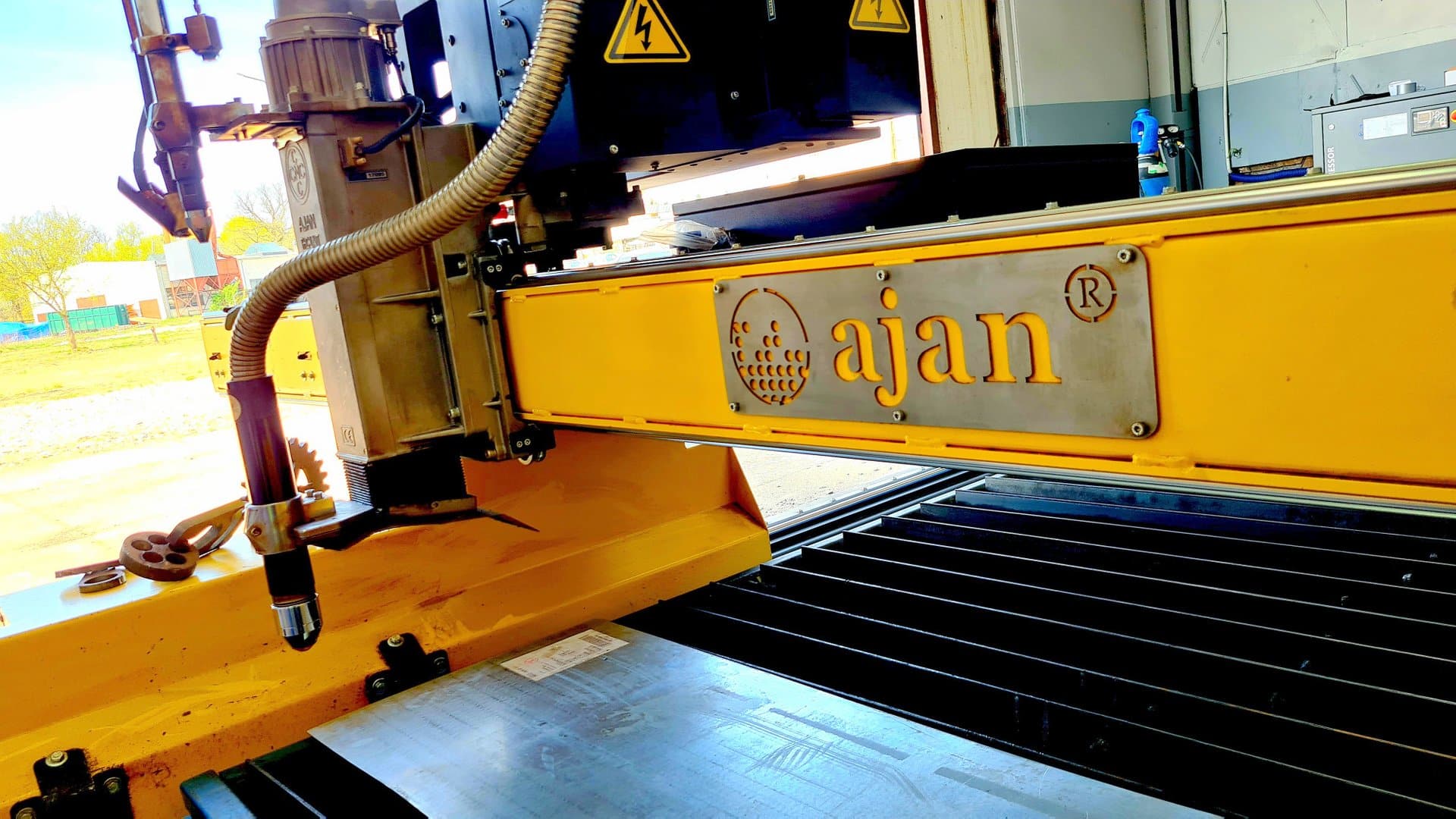

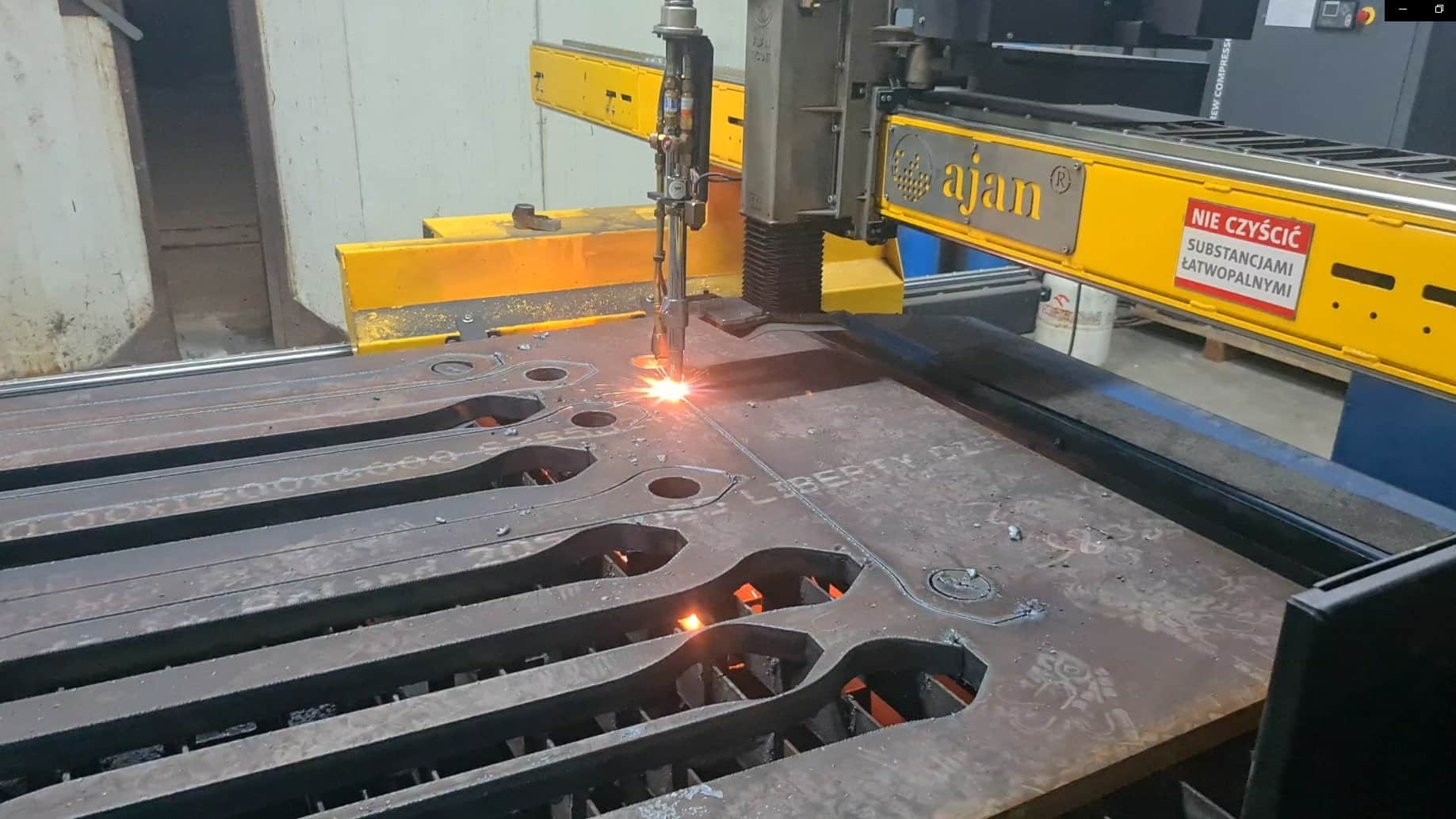

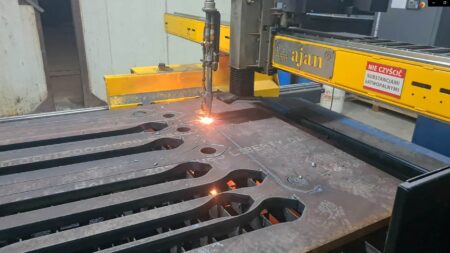

AJAN SHP 130 plasma cutting machine, built in Turkey in 2017, is designed for shape cutting in workpieces made of stainless steel, structural steel and aluminium. The plasma-gas cutting machine’s portal, with a length of 3000 mm and a width of 1500 mm, is made of a lightweight, stiffened profile, ensuring adequate stability during machining. Contamination occurring during cutting is eliminated by a reinforced sectional extraction table, increasing operator safety.

The machine is equipped with two torches – a gas torch with an MS type igniter ME TL/TR150, and a plasma torch SCT260, using which it can cut workpieces with a maximum thickness of 30 or 200 mm (structural steel, depending on the selected torch), 20 mm (stainless steel) and 25 mm aluminium. The special OPTHOLE technology used in the plasma-gas cutting machine guarantees high precision when burning holes in sheet metal.

The equipment of the plasma-oxygen cutting machine includes the CNC control AJANCNC 918L with the CAD/CAM software AJANCAM V8.14, allowing the programming of work modes and drawing the desired shapes in the workpieces, as well as the SHP130 plasma source with a power of 130 A.

Technical data of the AJAN SHP 130 plasma-gas cutting machine

- materials to be cut: structural steel, stainless steel, aluminium

- work table surface (L x W): 3000 x 1500 mm

- maximum cutting thickness (structural steel, plasma torch): 30 mm

- maximum cutting thickness (structural steel, gas torch): 200 mm

- maximum cutting thickness (stainless steel): 20 mm

- maximum cutting thickness (aluminium): 25 mm

- rapid feed rate: 15 m/min

- type of fuel gas: propane-methane

- power of plasma source: 130 A

- power consumption: 4 kW

- power supply: 3x 400 V; 50 Hz

Equipment of plasma-gas cutting machine

- CNC control: AJANCNC 918L

- CAD/CAM software: AJANCAM V8.14

- gas torch with MS igniter: ME TL/TR150

- plasma torch: SCT260

- plasma source: SHP130

- plasma-gas support: THC

- reinforced sectional extraction table

- ventilation extraction: AJW55

- automatic gas console: EAK130

- automatic gas console: CAK100

- linear and spot scribing module: MICROPLAZMA

- extension of machine Y axis by 700 mm

- function: MICROJOINT

- function: OPTHOLE

- cathode and electrode wear consideration system: OTO

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe