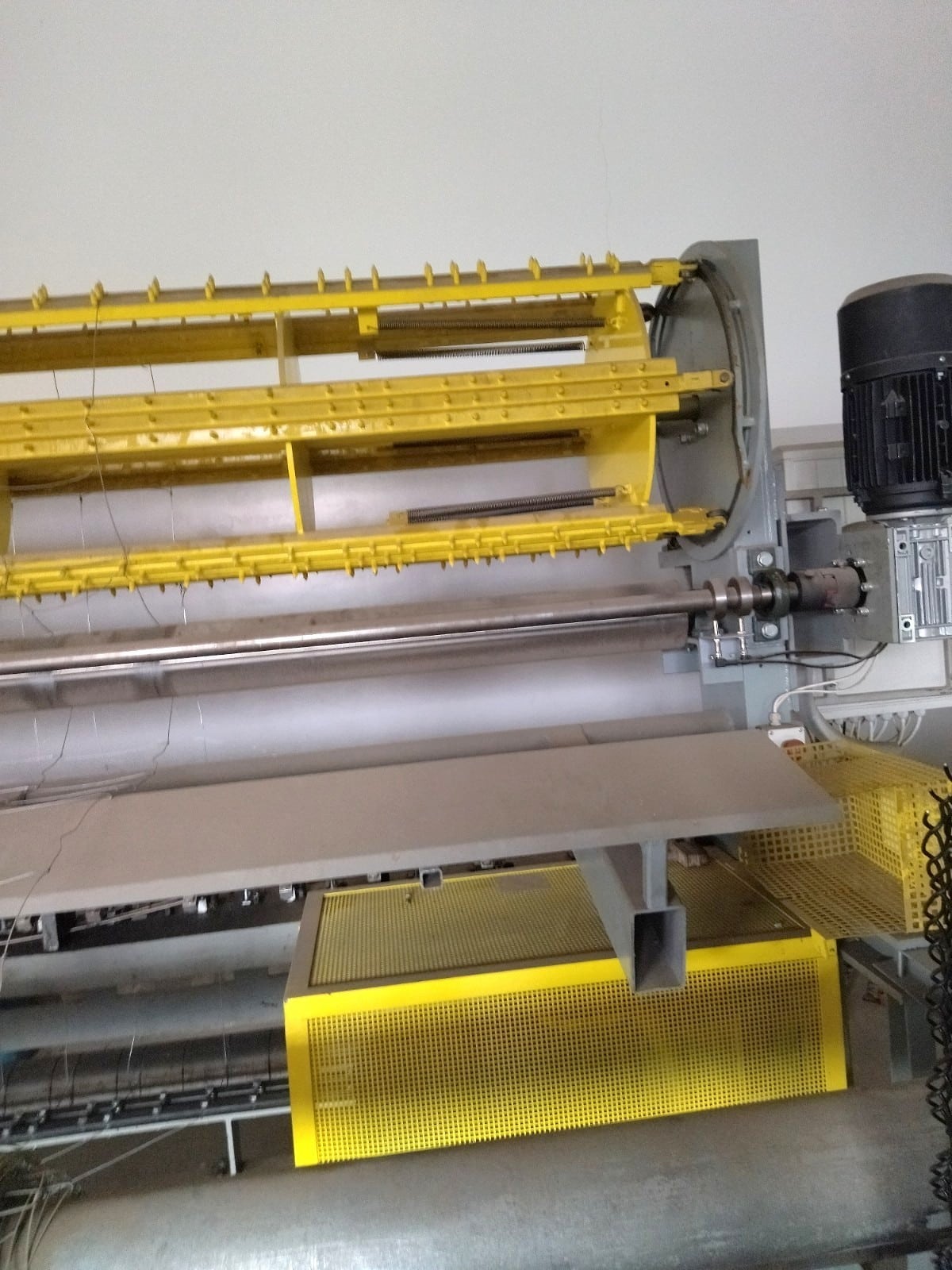

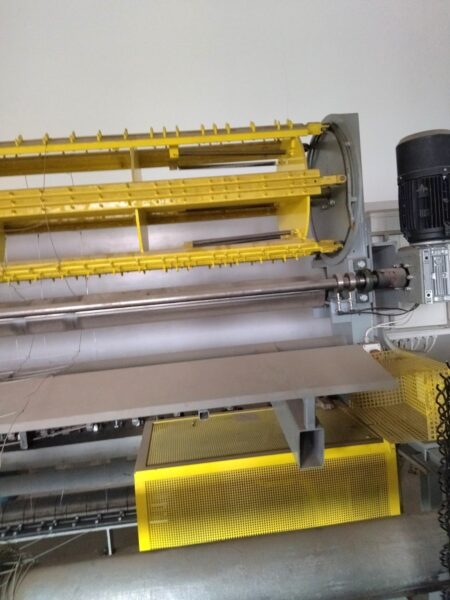

AL-2500/KX knotted wire mesh production machine was built in 2013 by KABEX P.P.H.U. The purpose of the machine is to produce damage-resistant and durable wire mesh made of galvanised wire with a maximum length of 100 metres and varied wire cross-sections.

The AL-2500/KX fixed knot net production line consists of:

– machine body (1 unit),

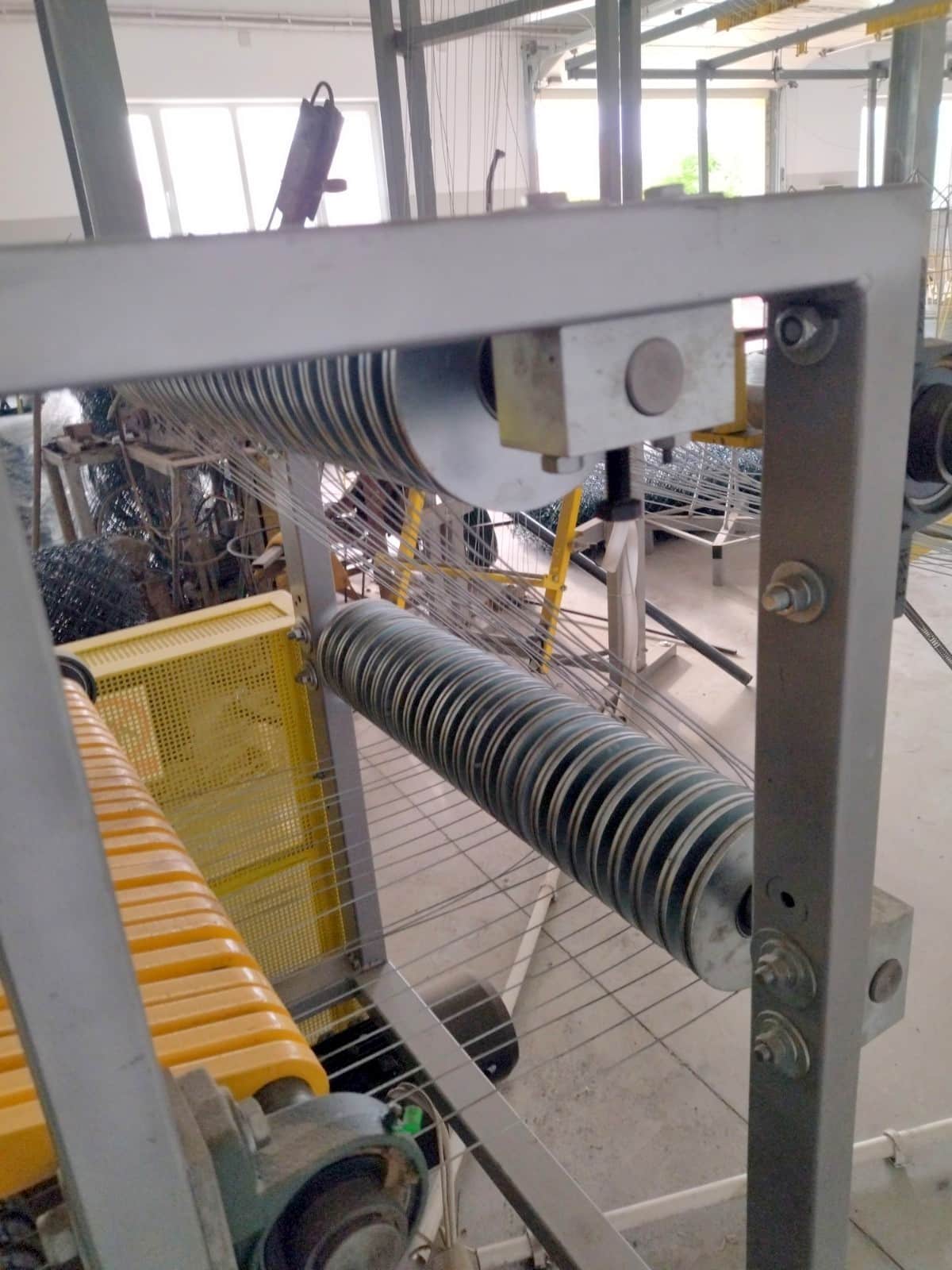

– guide roller with a brake to increase wire tension (1 unit),

– tool table with turning rollers and wire guide tubes and plates (1 unit),

– wire feeder with wheels that feed the appropriate length of wire onto the tool table for wire wrapping (1 unit),

– pulling drum (1 unit),

– mesh winding drum (1 unit),

– twisting mechanisms (27 units),

– guillotines (26 units),

– wire bending clamps (27 units),

– net stacking table, which performs a reciprocating motion in order to place the net coils tightly next to each other (1 unit),

– unwinding frame (1 unit),

– wire reel stands (53 units),

– unwinding baskets (53 units),

– safety barriers with sensor (2 units).

The machine starts braiding the mesh by starting the pulling drum and the wire feeder, whose task is to feed a certain amount of wire onto the mesh and the tool table. Once this step is completed, the wire is cut and the ends are bent by the guillotine and its cutter. At the same time, the wire bending clamps bend the other end of the cut section of wire.

The guillotine, together with the bending clamps, moves away and, in the meantime, the bending roller makes 8 revolutions in order to make the correct number of wrapping turns. At the end of the process, the guillotine returns to its initial setting, starting the entire net braiding cycle from the beginning. The knotted forestry net making machine AL-2500/KX allows for a maximum of 50 such cycles in one minute.

Technical parameters of the AL-2500/KX forest net production machine

- length of the produced net: 50 or 100 m

- height range of manufactured net: 0.3-2.5 m

- wire diameter range: 1.6-3 mm

- spacing of wires in the net: 16×5 cm, 3×10 cm, 2×15 cm, 3×20 cm, 2×25 cm

- number of wires: 29-53 pcs.

- maximum moulding speed: 1.5 m/min

- accuracy of cutting length: ± 1 mm

- net roll winding mechanism: smooth drum with a mechanism for locking the net in the shaft

- net twisting mechanism: hinge, guillotine, bending clamp

- cutting of net roll: manual (after winding up the desired length of the net)

- power consumption: 5.5 kW

- power supply: 400 V; 50 Hz

- space requirement (with unwinder): approx. 170 m2

- dimensions (L x W x H): 4500 x 2200 x 2100 mm

- weight of machine AL 2500/KX: 2200 kg

Equipment of the knotted wire mesh making machine

- PLC control: ARRAY APB-22-MRDL

- operator panel SH-300

- geared motor (feeder): 1.5 kW, 83 rpm

- geared motor (turning): 5.5 kW, 83 rpm

- geared motor (drum): 2.2 kW, 15 rpm

- geared motor (guillotine): 4 kW, 90 rpm

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe