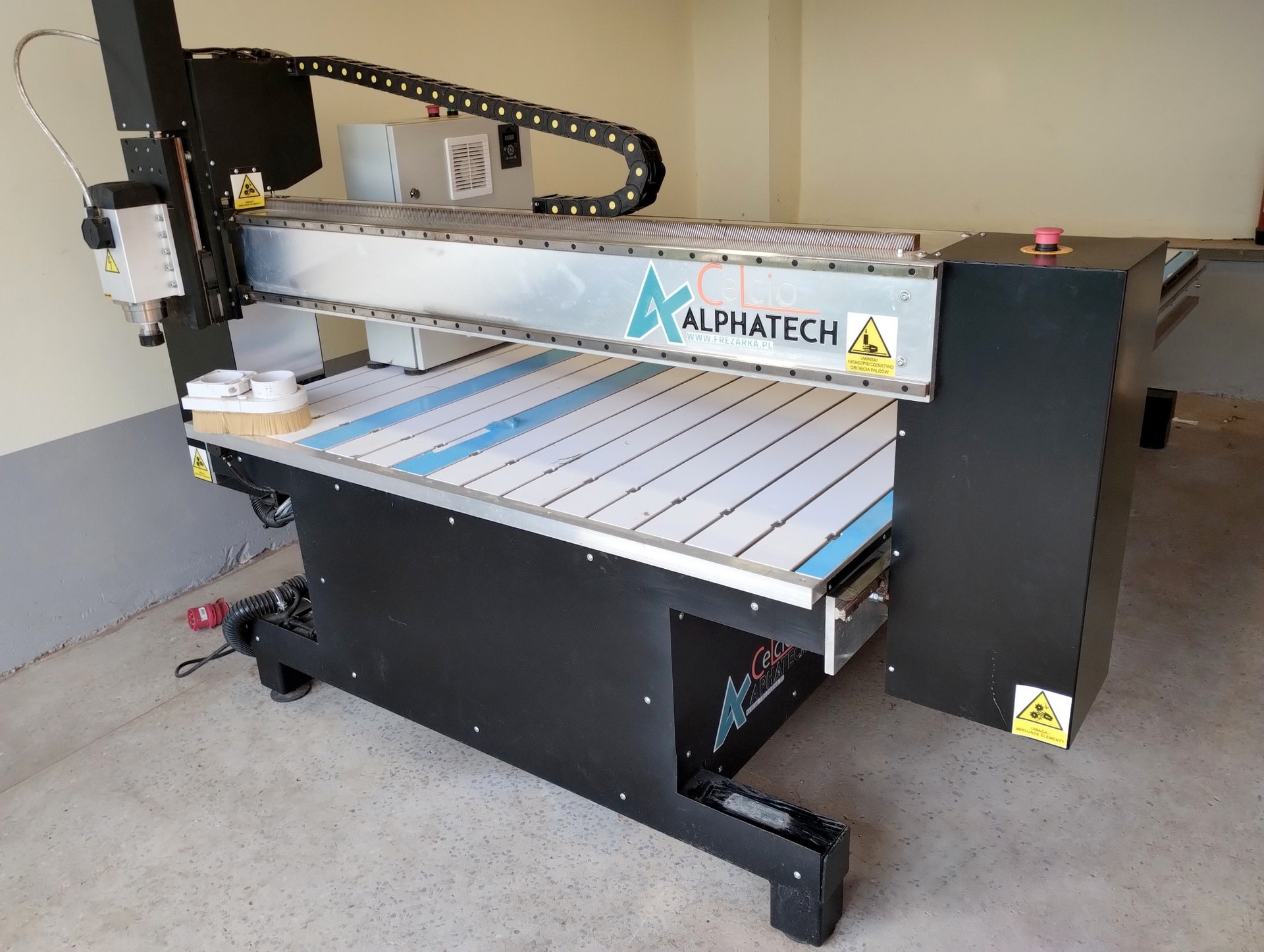

ALPHATECH CELCIO 1525 CNC milling machine was built in 2023 in Poland. The machine used for machining materials made of soft metals, plastics and wood, works perfectly even in the most demanding unit and small batch production thanks to its reinforced construction and reliable components. The reliable 6 kW spindle guides the tool precisely during milling, guaranteeing excellent precision and quality of machining.

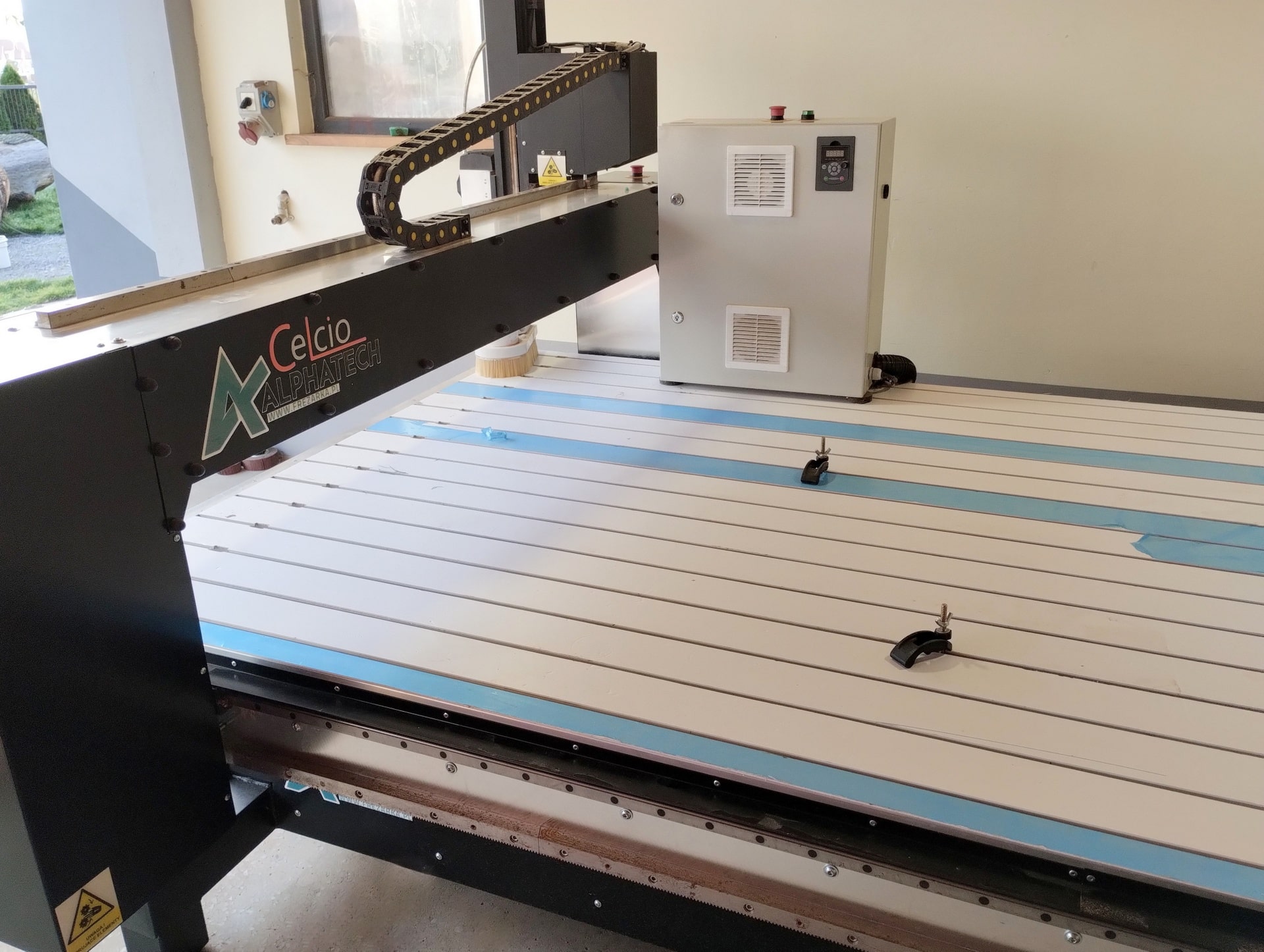

The CELCIO 1525 milling machine also features a large working area with a high-quality T-slot table with a length of 1500 mm and a width of 2500 mm, which allows you to easily mount the material and additional equipment such as a vice. The whole machine is controlled via a CNCGraf CNC controller with a very useful NESTING function, responsible for arranging 2D parts in such a way as to save space on the workpiece as much as possible. The total weight of the machine is 1000 kg.

Technical data of the ALPHATECH CELCIO 1525 milling machine

- machinable materials: soft metals, plastics, wood

- work table surface (L x W): 1500 x 2500 mm

- feed rate in the X/Y/Z axis: 1550/2550/250 mm

- Z-axis travel: 180 mm

- Z-axis clearance: 200 mm

- working speed: 3400 mm/min

- repositioning speed: 3800 mm/min

- positioning accuracy: 0.1 mm

- repeatability: ± 0.1 cm

- spindle drive power: 6 kW

- transmission of drive in X,Y axis: toothed rails

- transmission of drive in Z axis: ball screw

- power supply: 230 V

- dimensions (L x W x H): 2000 x 3000 x 1700 mm

- weight of machine: approx. 1000 kg

Equipment of the ALPHATECH CNC milling machine

- CNC controller: CNCGraf

- stepper motors in X,Y,Z axes

- tool length sensor

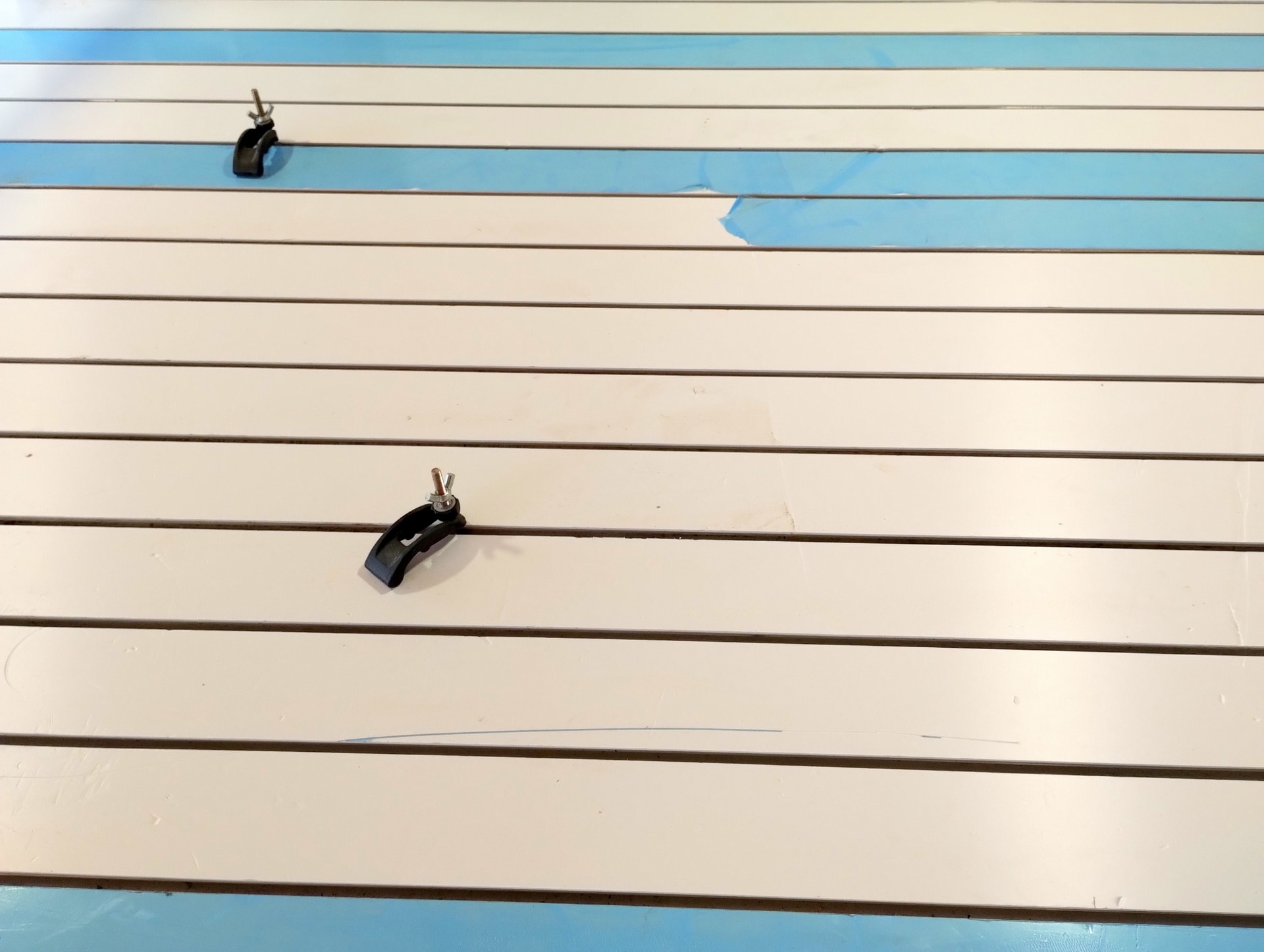

- T-slot work table

- trapezoidal guides

- main switch

- USB port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe