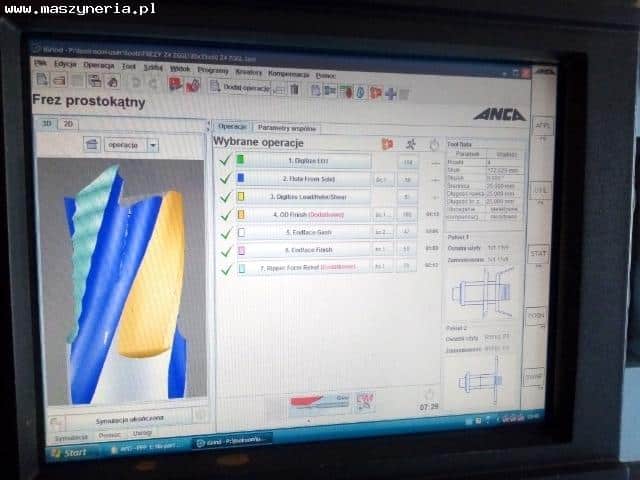

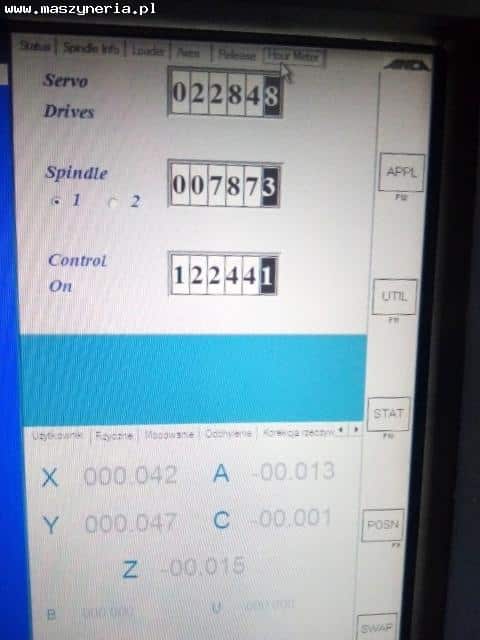

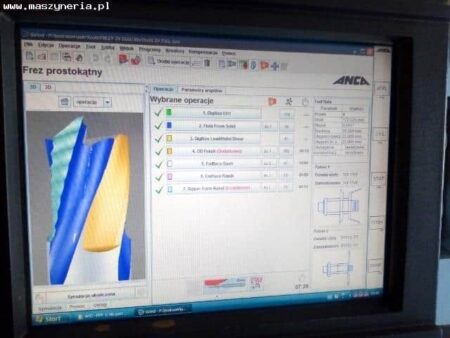

ANCA GX7 CNC Tool Grinder was built in 2011. The machine can process objects with a maximum length of 370 mm and a diameter of 240 mm. It is equipped with four axes and numerical control RN32.1-1, which enables automatic processing of workpieces, while increasing the efficiency of the grinder. The rotational speed of the grinding spindle is 0-8500 rpm. The grinder can be used for the production and regeneration of various types of tools intended for wood and metal processing. In addition, it is equipped with, among others, a probe, automatic central lubrication and an automatic fire extinguishing system.

Technical parameters of the ANCA GX7 CNC universal grinding machine

– 4 axles

– rotary table rotation range (C axis): +/- 307 degrees

– workpiece diameter: 240 mm

– maximum workpiece length: 370 mm

– maximum wheel diameter: 200 mm

– maximum efficiency: 9 kW

– grinding spindle speed: 0-8500 rpm

– longitudinal travel (X axis): 439 mm

– vertical travel (Y axis): 464 mm

– transverse travel (Z axis): 274 mm

– working head: ISO 50

– connection power: approx. 20 kW

– dimensions (L x W x H): 2170 x 2930 x 2280 mm

– machine weight: approx. 4500 kg

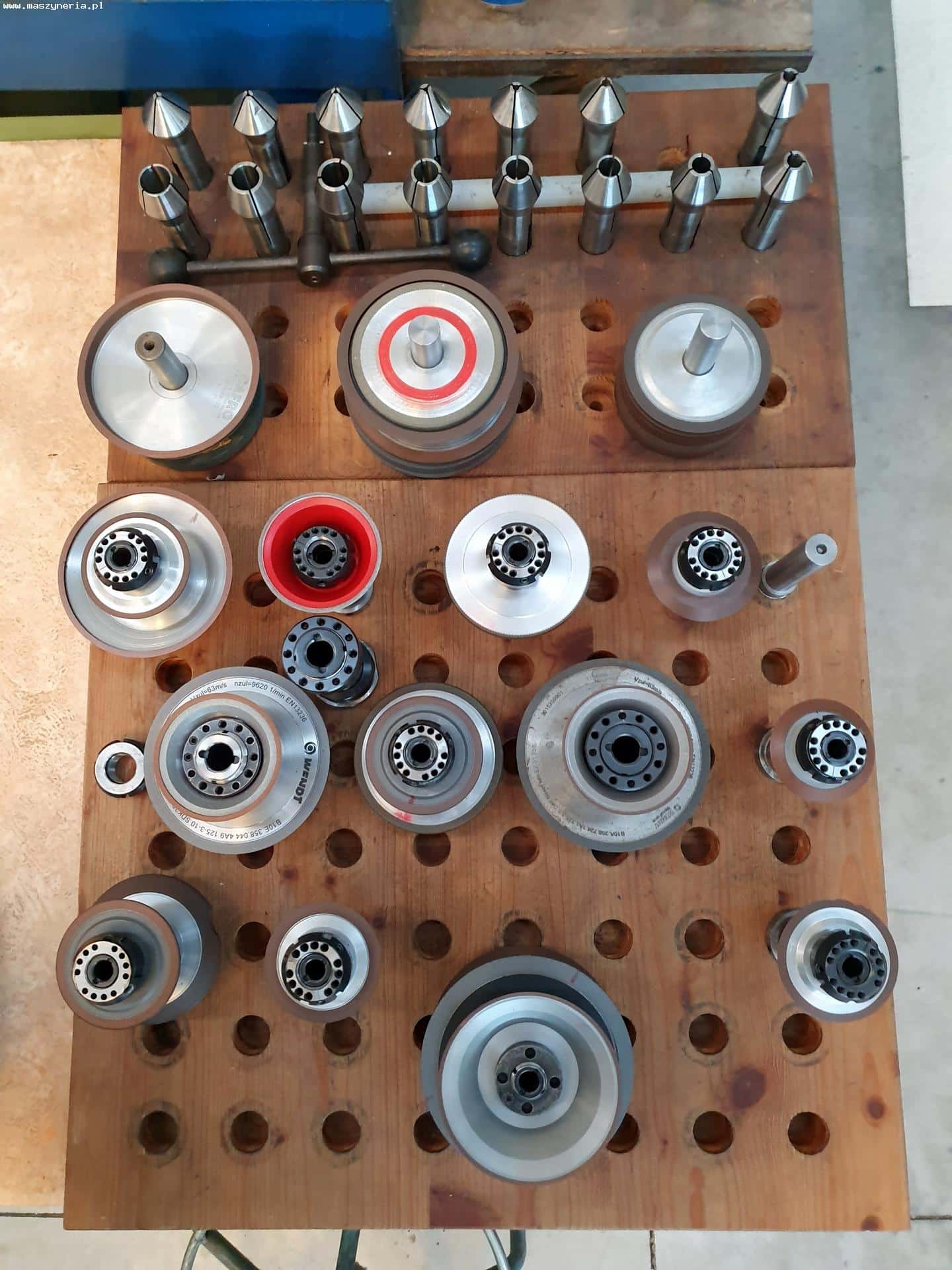

Accessories for CNC tool grinder ANCA GX7

– CNC control: RN32.1-1

– 3D simulator ISIDE MASCHINE

– probe

– automatic central lubrication

– pneumatic clamping of the workpiece

– grinding wheel flanges: 12 pcs

– electrostatic fog extractor

– automatic fire extinguishing system

– belt filter system: 200 l, with oil cooler

– technical protocol

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano