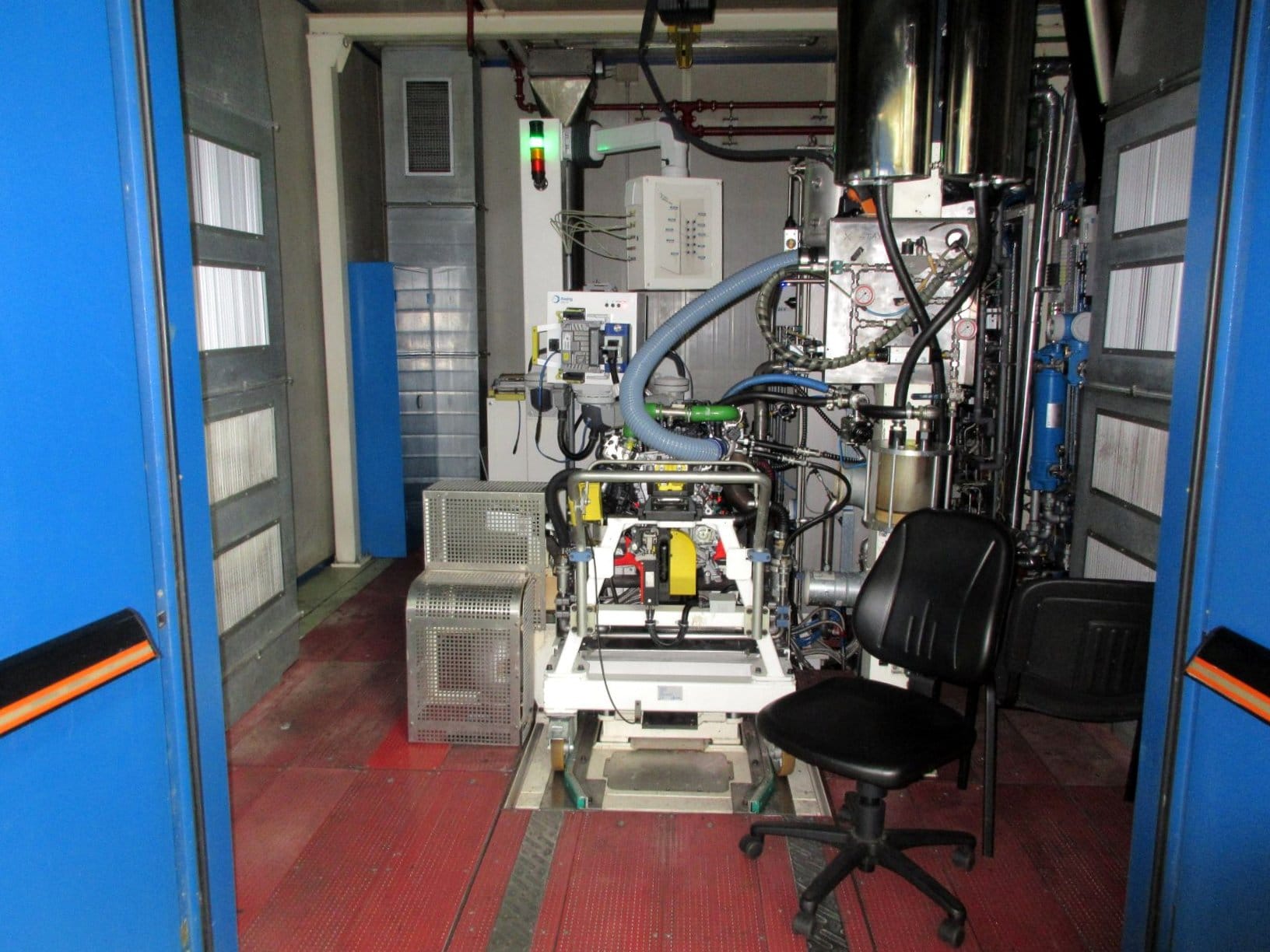

The ASSING RIGAL-D hot test engine bench was manufactured in 2019 by the Italian company ASSING S.P.A The machine is used to simulate standard test cycles and external effects.

The “hot” engine test, is the process in which the engine is tested for its performance. Compared to the “cold” test, this test takes longer because the engine must reach the required thermal conditions close to those that can be observed in the vehicle. The engine is supplied with fuel, coolant and air, as well as engine oil. The parameters tested are, for example, torque output, oil pressure and temperature, and exhaust gas temperature.

The ASSING RIGAL-D testing station performs test cycles in manual, semi-automatic and automatic mode, with the operator performing only control tasks. The system allows simulation of vehicle behaviour, including its inertia, transmission losses, gear changes or external effects such as wind, road, uphill or downhill driving. It also allows the automatic execution of test cycles prescribed by international standards or the configuration of customised cycles.

Main features of the ASSING RIGAL-D machine

- DYNAS software package

- test cycles in manual, semi-automatic and automatic mode

- possibility to configure your own cycles

- simulation of vehicle behaviour and other various external effects

- easy to use

- modular solutions

- integration and communication with test cell equipment (instrumentation and PLC)

- voltage: 230 V

- frequency: 50 Hz

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe