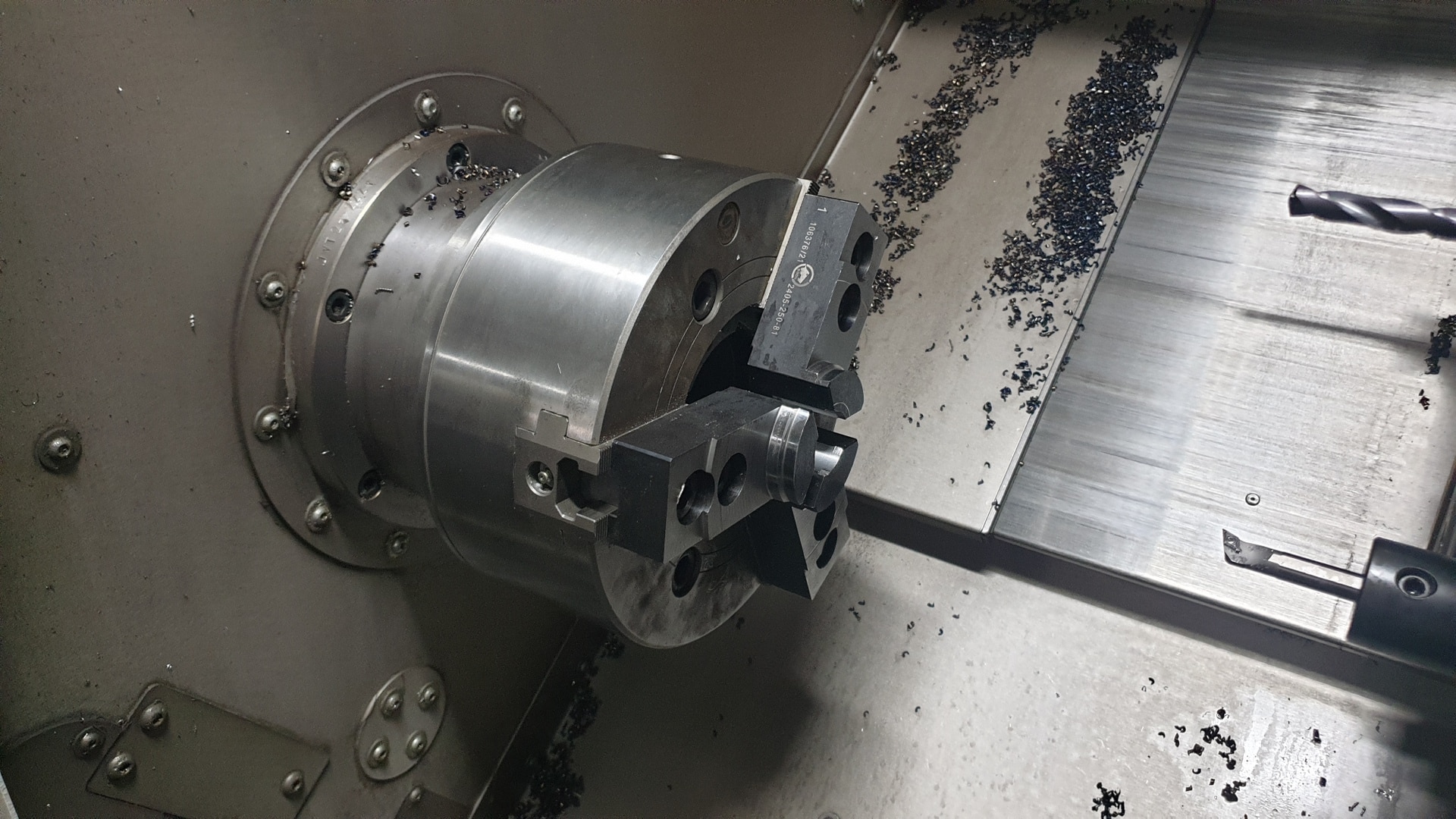

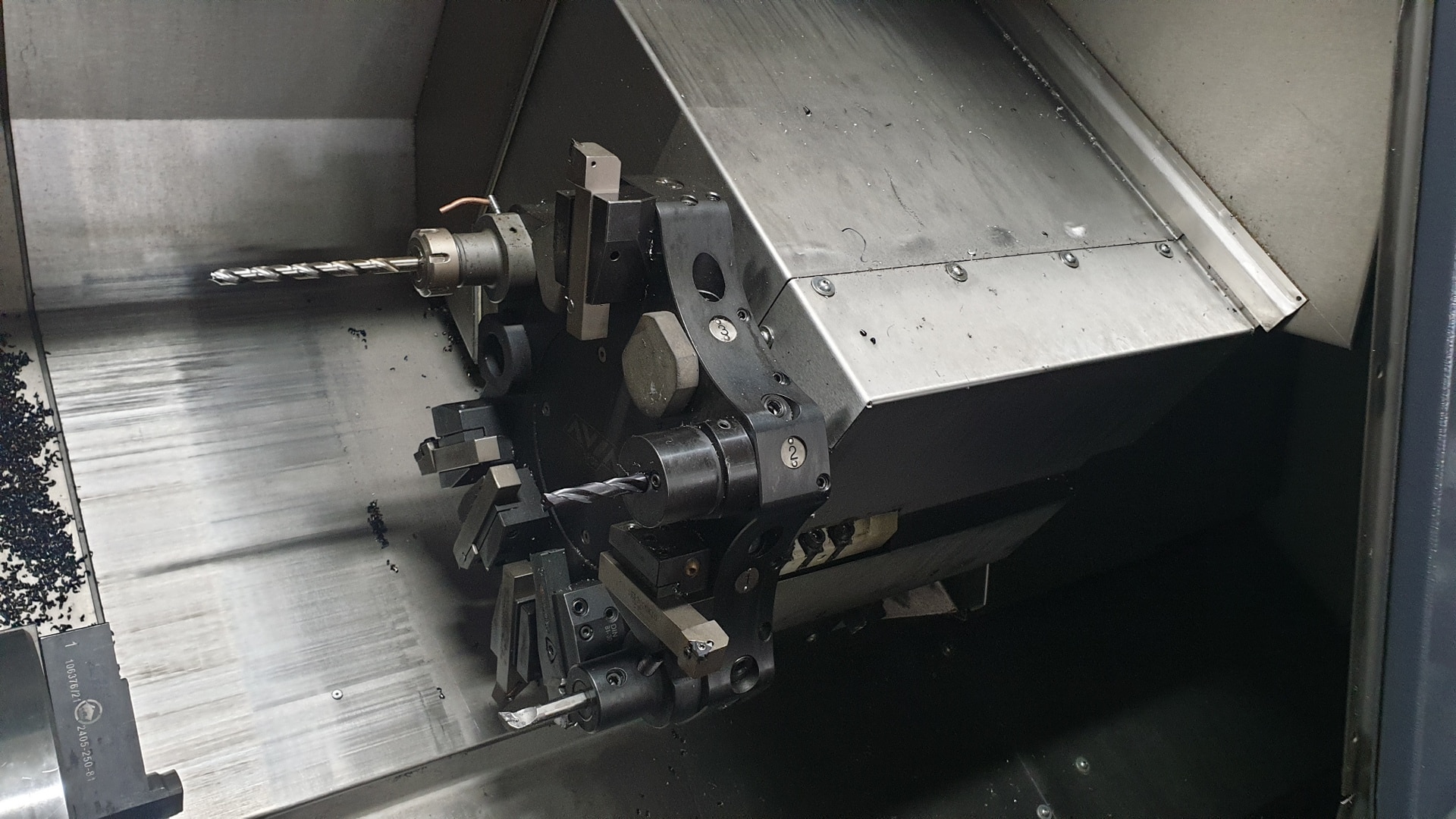

AVIA AVIATURN 35 CNC turning center was built in 2022 in Poland. The machine, designed for precision machining of workpieces with a maximum diameter of 350 mm, has been equipped with many state-of-the-art solutions and high-quality components that ensure excellent turning results. The workspace includes, among others, a 12-position turret and a reliable spindle driven by a belt drive with encoder.

The AVIAturn 35 CNC lathe is also distinguished by its richly ribbed, single-piece cast iron bed. The bed, which is inclined at 35°, effectively dampens all vibrations and oscillations, resulting in, among others, improved workpiece surface quality and increased cutting tool life. The machine’s extensive equipment includes, among others, a hydraulically movable tailstock, a tool probe and a SIEMENS CNC control in its most powerful version with a wide range of built-in fixed cycles and 16 GB of additional memory. The total weight of the machine is approximately 3850 kg.

Technical specifications of the AVIA AVIATURN 35 CNC metal lathe

- maximum turning diameter: 350 mm

- maximum bar diameter: 65 mm

- maximum turning length: 600 mm

- feed in the X/Z axis: 220/610 mm

- rapid traverse in the X/Z axis: 25/30 m/min

- maximum spindle rotational speed: 5000 rpm

- spindle passage: 75.5 mm

- spindle tip: A2-6

- spindle drive motor power (100/60% ED): 13.5/16.2 kW

- spindle drive motor torque (100/60% ED): 157/189 Nm

- spindle drive type: belt drive

- bed inclination angle: 35°

- tool clamping: axial (from disc face)

- turret rotation time (tool-tool): 0,4 s

- turning chisel cross-section: 20×20 mm

- maximum boring chuck diameter: 32 mm

- single block machining time: 6 ms

- total installed power: 28 kVA

- power supply: 3x 400 VAC; 50 Hz

- dimensions (L x W x H): 2860 x 1660 x 2120 mm

- length of machine with chip conveyor: 3920 mm

- weight of machine: approx. 3850 kg

Equipment of the AVIA CNC lathe with inclined bed

- SIEMENS SINUMERIK 828D CNC controller with ShopTurn 3D overlay

- hydraulically movable tailstock

- MARPOSS tool probe with automatic arm and measuring cycles

- BISON 3-jaw hydraulic, self-centring chuck with set of soft and hard jaws

- Morse 5 high-speed lathe center

- digital servo drives and drive motors for axes and spindle

- 12-position turret (servo) with VDI 30 toolholders

- belt chip conveyor

- automatic lubrication system for guides and gears

- tool water cooling system

- touch screen control panel 15.6″

- roller bearing slides in the X,Z axes

- telescopic stainless steel guideway covers

- double-sided ball-bearing mounted double-nut spur gears

- inclined bed

- 3-piece HIRTH clutch for head position locking

- through-hole hydraulic chuck cylinder

- electronic handwheel

- oil separator from coolant

- foot switches for lathe chuck operation

- network card

- coolant hand gun

- electric cabinet heat exchanger

- workspace illumination

- lamp indicating work status

- CE declaration of conformity

- USB port

- PCMCIA port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe