BATTENFELD BA 1500/630 CDC injection moulding machine was built in Austria in 1997. Used in the production of plastic parts, the machine features high reliability and a steel construction equipped with the best components to maximise overall productivity and efficiency.

Injection moulds placed on 740 x 740 mm platens are closed with a force of 150 tonnes by a central hydraulic clamping system with a magnetic air valve and hydraulic ejector. The UNILOG 4000 CNC control located on the body of the injection moulding machine with its intuitive interface, allows programming of the operating modes and control of the process parameters. The total weight of the BATTENFELD BA 1500-630 CDC machine is 9000 kg.

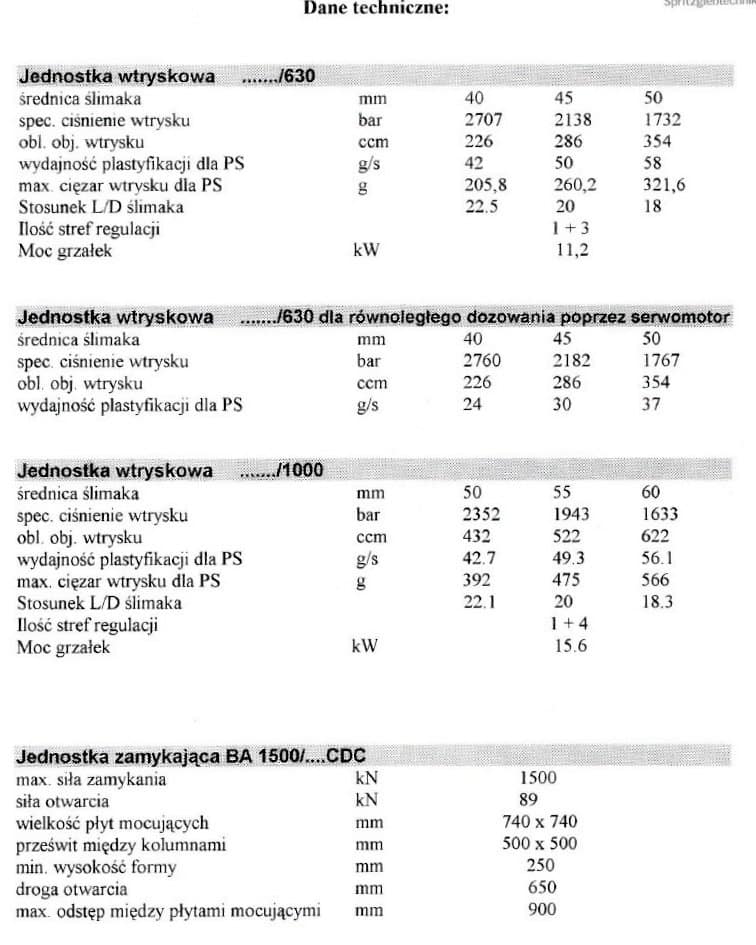

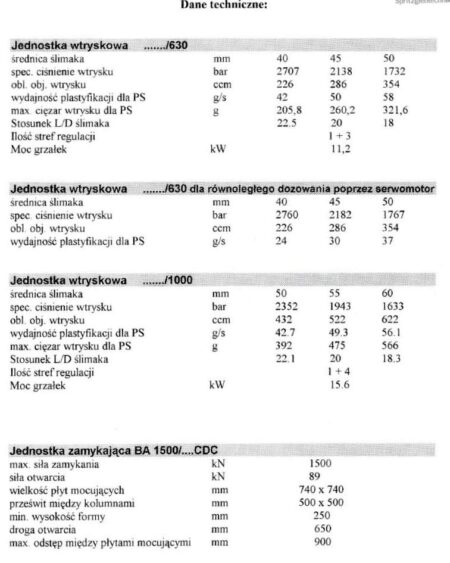

Technical data of the BATTENFELD BA 1500/630 CDC injection moulding machine

- CNC control: UNILOG 4000

- clamping force: 150 t (1500 kN)

- opening force: 8.9 t (89 kN)

- screw diameter: 50 mm

- screw stroke: 180 mm

- injection weight: 322 g

- mould plate size: 740 x 740 mm

- minimum mould height: 250 mm

- mould opening stroke: 650 mm

- injection volume: 354 cm3

- injection pressure: 1732 bar

- plasticisation capacity: 58 g/s

- maximum distance between plates: 900 mm

- distance between columns: 500 x 500 mm

- ejector stroke: 160 mm

- ejector force: 39 kN

- injection nozzle stroke: 400 mm

- injection nozzle thrust: 99 kN

- heating power: 11,2 kW

- number of heating zones: 1+3

- hydraulic operating pressure: 210 bar

- power supply: 230/400 V; 50 Hz

- weight of 1500/630 CDC machine: 9000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe