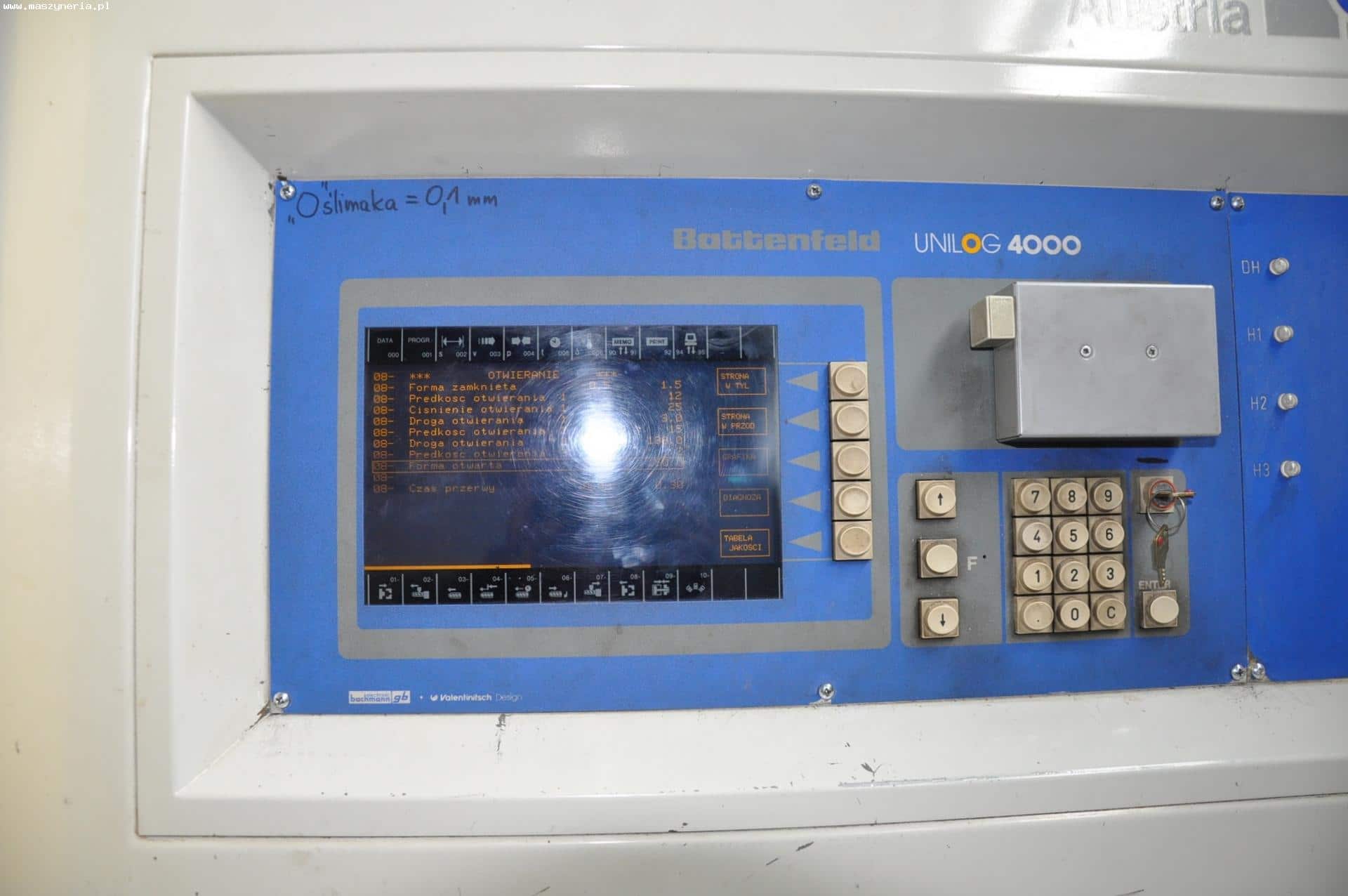

The BATTENFELD BA 500 CD injection molding machine was manufactured in Austria in 1989. It is equipped with numerical control UNILOG 4000 B. The machine has a maximum clamping force of 50 tons and an ejector force of 17.5 kN. The surface of the plates for fixing the molds is 480×480 mm, and the spacing between the columns is 304×304 mm. The injection molding machine has a screw with a diameter of 30 mm and a maximum injection volume of 99 cm3.

Technical parameters of Battenfeld BA 500 CD injection molding machine

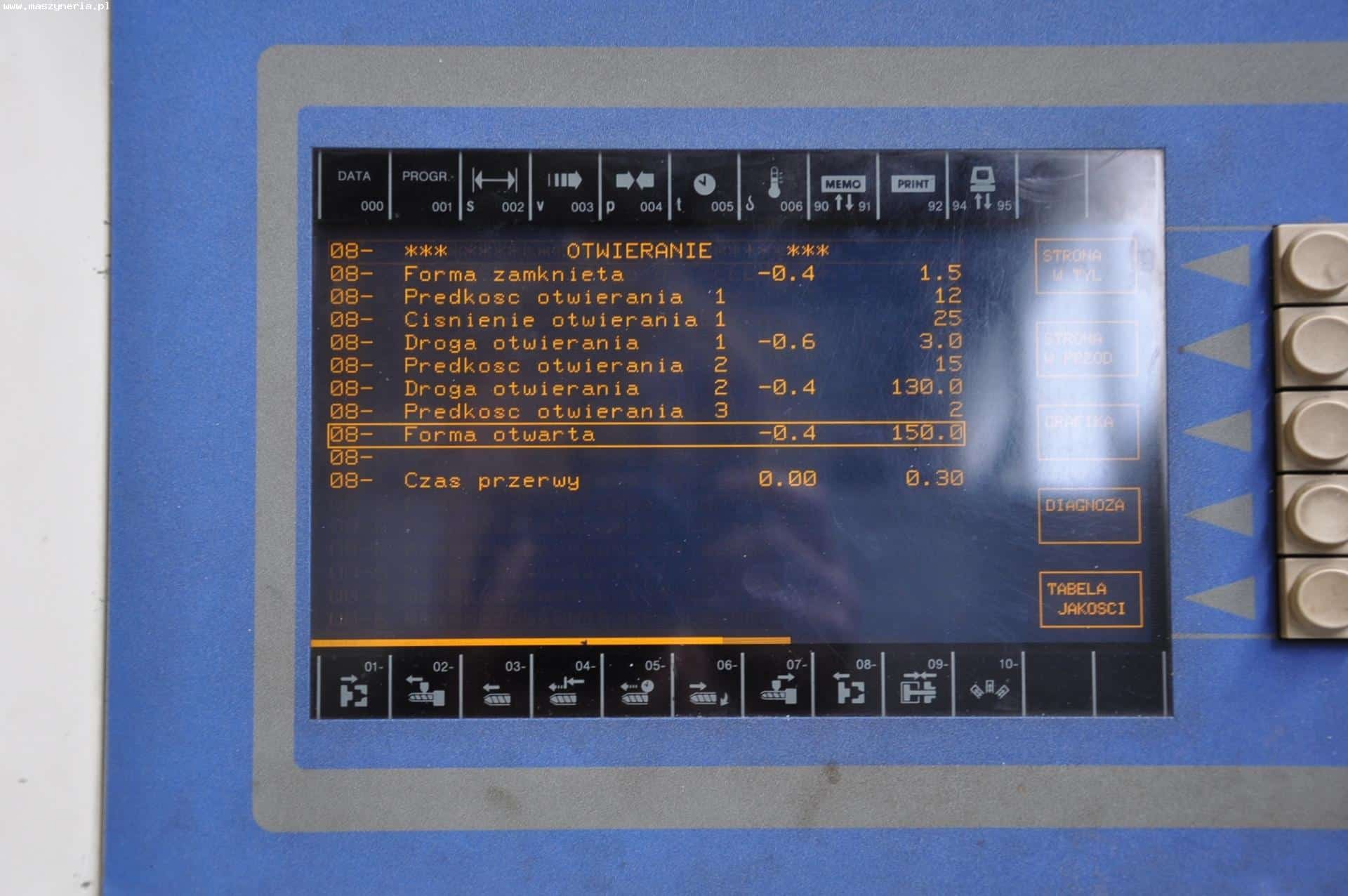

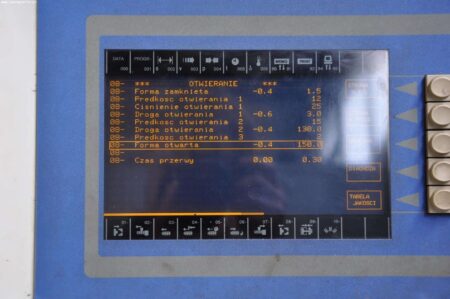

– CNC control: UNILOG 4000 B

– maximum clamping force: 50 tons, 500 kN

– opening force: 40 kN

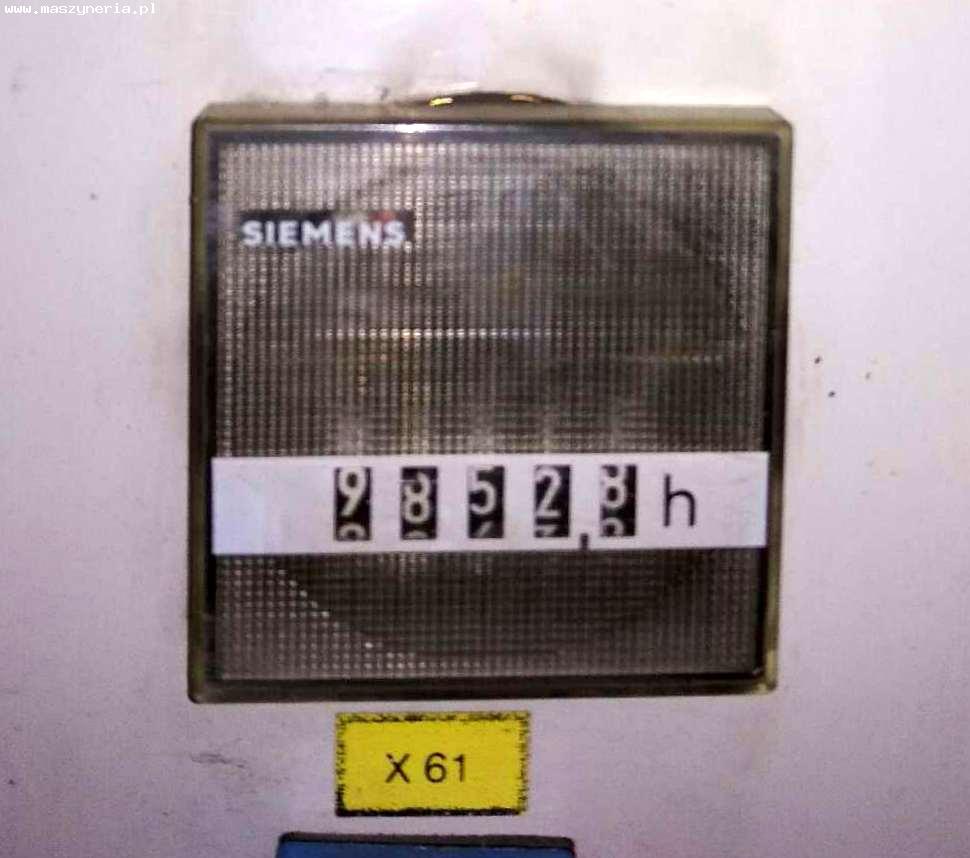

– meter reading: 9852.8 h

– maximum injection volume: 99 cm3

– maximum injection pressure: 2022 bar

– maximum processing temperature: 450 degrees C.

– screw: 30 mm

– plasticizing capacity: 10.5 g / sec.

– screw stroke: 140 mm

– screw speed: 0-290 min.

– nozzle stroke: 200 mm

– heating power of heaters: 7.88 kW

– outer plate size: 480 x 480 mm

– spacing between columns: 304 x 304 mm

– column diameter: 50 mm

– min. mold height: 150 mm

– mold opening stroke: 375 mm

– max. mold opening: 525 mm

– mold closing system: hydraulic

– ejector force: 17.5 kN

– ejector stroke: 160 mm

– dry cycle: 35 1 / min.

– nozzle pressure: 57.7 kN

– motor with pump: 11 kW

– oil tank capacity: 185 l

– dimensions: 3.23 x 1.3 x 1.84 m

– machine weight: 2500 kg

Equipment of BATTENFELD BA 500 injection molding machine

– hot runners

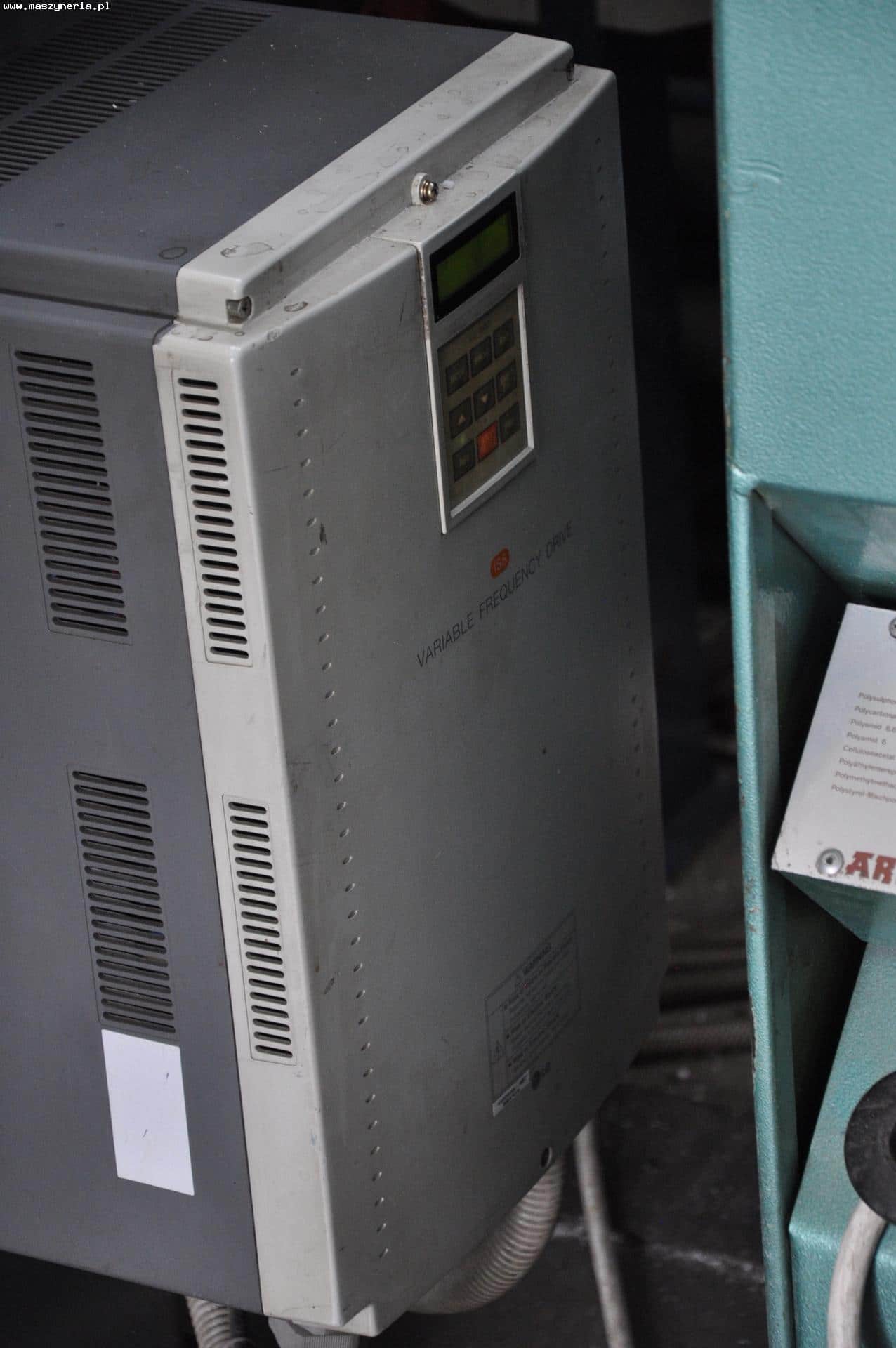

– inverter

– moldings feeder (conveyor belt)

– crane

– pillows: 4 pcs.

– chain block, 0.5 t

– Technical Documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano