BAYKAL APHS 41240 CNC hydraulic press brake, built in 2019 in Turkey is designed for bending sheet metal with a maximum length of 4100 mm. Equipped with state-of-the-art technologies and reliable components, the machine performs machining with a force of as much as 240 tonnes. One such technology is the very useful function of automatic CNC deflection arrow compensation, which ensures that the desired angle is achieved along the entire length of the bent part. Another feature is a special safety system from the renowned German brand FIESSLER ELEKTRONIK, which covers the entire workspace. This system automatically stops the machine if the laser beam is interrupted, guaranteeing a high level of operational safety. The APHS 41240 CNC press brake was used for just 483 hours. The total weight of the machine is 16000 kg.

Technical specifications of the BAYKAL APHS 41240 press brake

- number of axes: 4

- maximum press force: 240 t

- maximum sheet metal length: 4100 mm

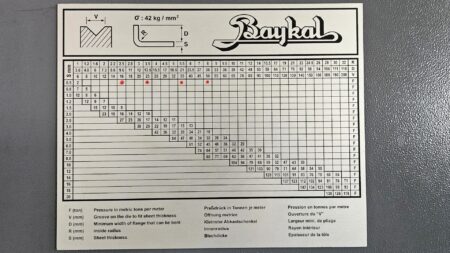

- maximum sheet metal thickness: 10 mm

- reach: 700 mm

- slider stroke: 420 mm

- stopping time: 80 ms

- upper tool weight: 150 kg

- bottom tool weight: 200 kg

- operating hours: 483 h

- distance between columns: 3550 mm

- power: 26 kW

- working pressure: 265 bar

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 4875 x 1875 x 3020 mm

- weight of machine: 16000 kg

Equipment of the BAYKAL press brake

- CNC controller: DELEM DA-66T

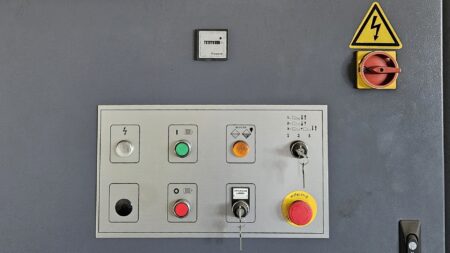

- light curtains: FIESSLER ELEKTRONIK

- automatic CNC deflection arrow compensation

- quick punch clamping system

- front supports on roller tracks

- foot switch control

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe