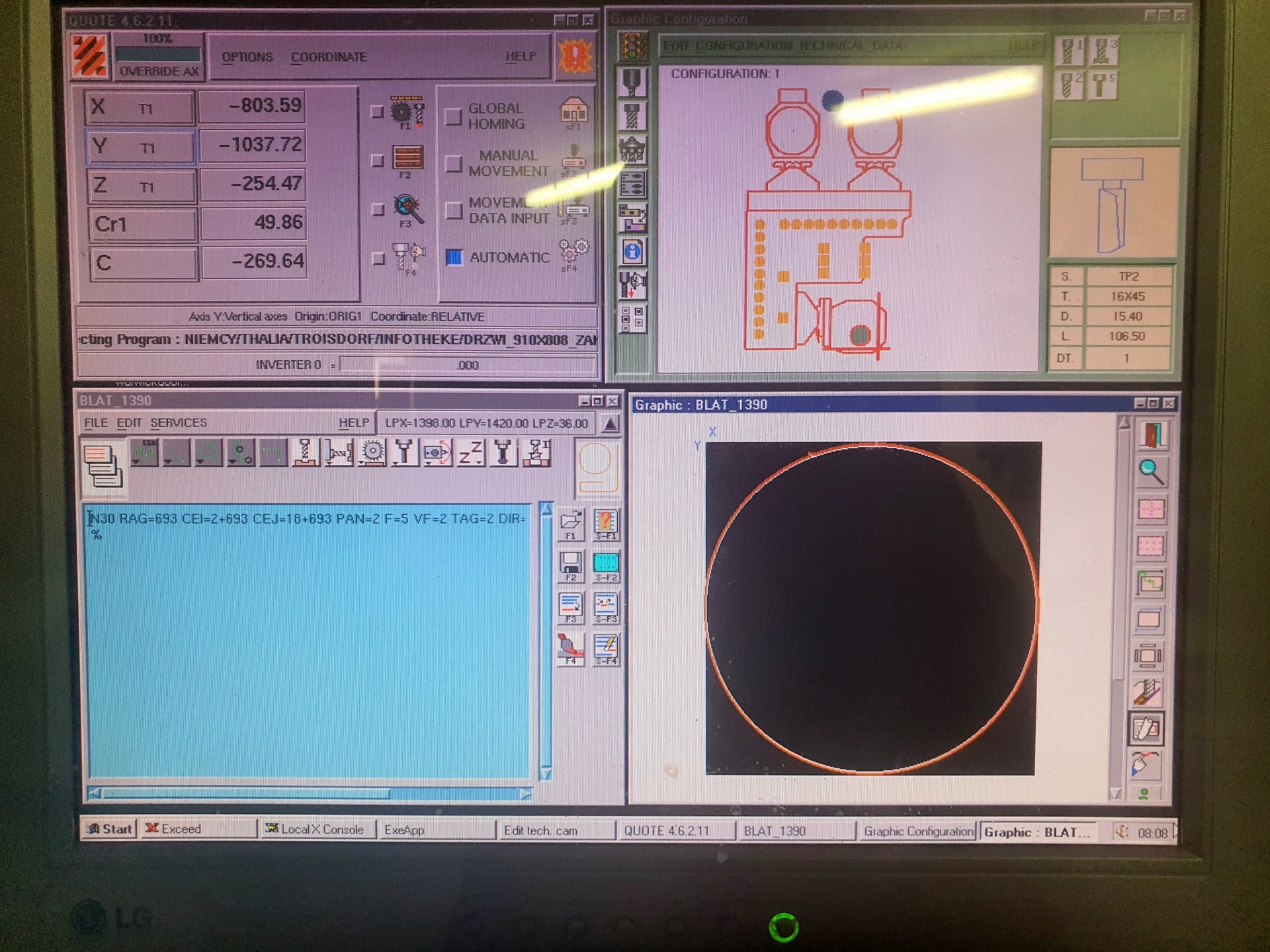

BIESSE ROVER 30 L3 milling machine manufactured in 2000 in Italy, is designed to perform the cutting, routing and boring process in MDF, plywood and other lightweight materials. The machining centre is controlled by the intuitive BIESSE XNC CNC controller, which uses a multitasking operating system to dynamically display tool paths and control several processes simultaneously.

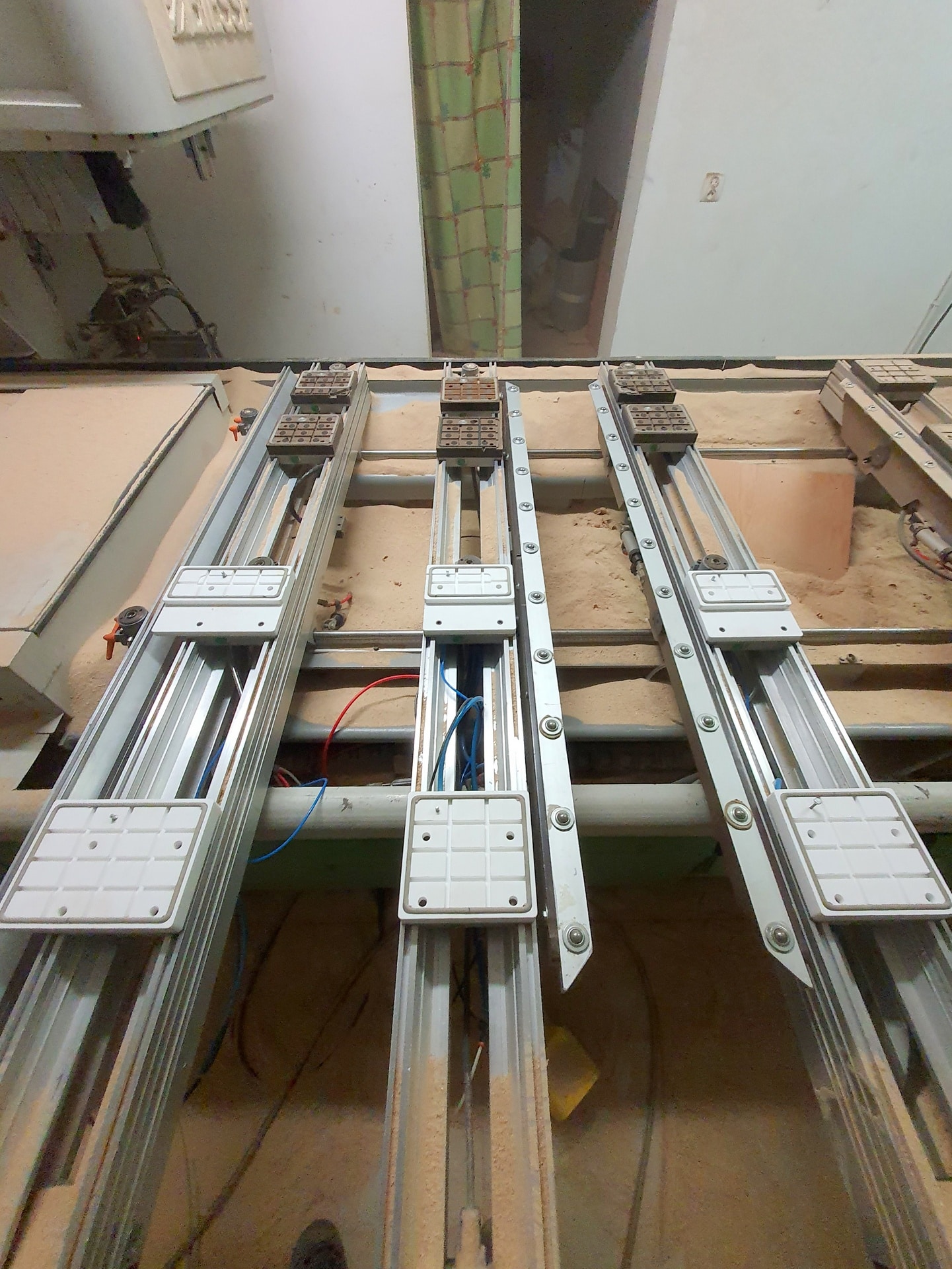

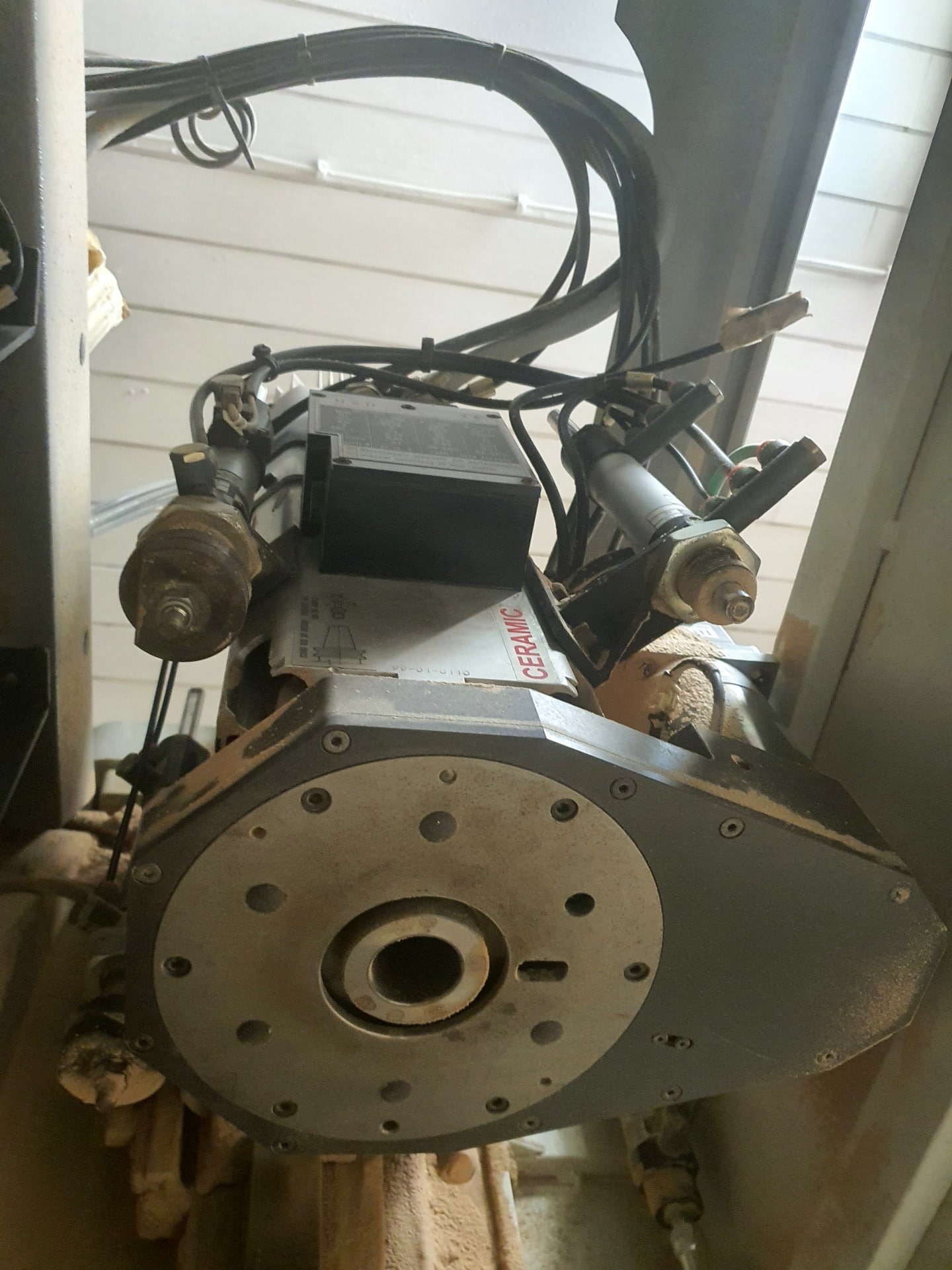

The machining process takes place on a large work area with a length of 4400 mm and a width of 1750 mm, with a special pneumatic workpiece locking/unlocking system that allows easy handling and assembly of both narrow and heavy panels. The panel is machined on all sides by two independent high-speed spindles with excellent precision and quality. The BIESSE CNC wood milling machine is equipped with a 3-position linear tool magazine and a 12-position turret tool magazine with ISO 30 tool holder.

Technical data of the BIESSE ROVER 30 L3 milling machine for wood

- CNC control: BIESSE XNC

- work area dimensions (L x W x H): 4400 x 1750 x 150 mm

- number of spindles: 2

- number of horizontal drills (X axis): 6

- number of horizontal drills (Y axis): 2

- number of vertical drills: 20

- 12-position turret tool magazine

- 3-position linear tool magazine

- tool holder: ISO 30

- power: 20 kW

- air suction speed: 30 m/1

- minimum pneumatic supply: 7 bar

- power supply: 380 V; 50 Hz

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe