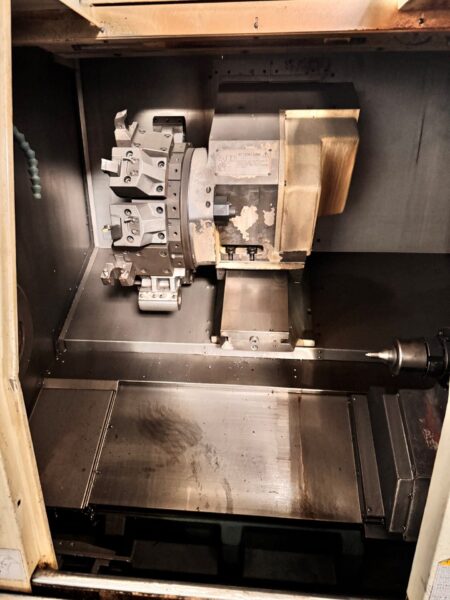

BIGLIA B658 CNC turning center was built in 2008 in Italy by OFFICINE E. BIGLIA & C. S.p.A. The machine, designed for precision machining of workpieces with a maximum diameter of 380 mm, has, among others, a 12-position turret, a reliable spindle and an automatic tailstock. All process parameters, in turn, are programmed in an intuitive FANUC CNC control with many useful functions that facilitate the daily operation of the machine. The BIGLIA B 658 CNC lathe weighs 6000 kg.

Technical specifications of the BIGLIA B658 lathe

- maximum turning diameter: 380 mm

- maximum bar diameter: 80 mm

- maximum passage: 620 mm

- maximum turning length: 650 mm

- feed in the X/Z/B axis: 220/650/660 mm

- rapid traverse in the X/Z/B axis: 20/24/12 m/min

- spindle rotational speed: 30-3000 rpm

- spindle bore diameter: 90 mm

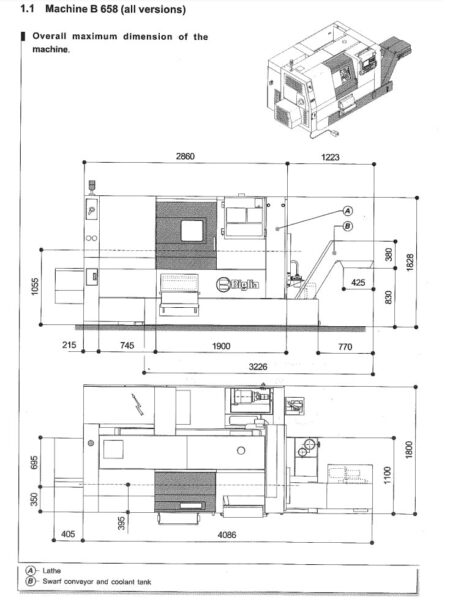

- spindle centre height: 1055 mm

- front bearing inner diameter: 130 mm

- spindle end: ASA 8″

- spindle drive power: 26/22 kW

- lathe chuck diameter: 315 mm

- collet DIN 6343

- external turning tool shank: 25×25 mm

- internal turning tool shank: ⌀ 40 mm

- turret indexing (by 1 position): 0,1 s

- maximum tailstock clamping force: 1080 Kgf

- coolant tank capacity: 250 l

- coolant pump capacity: 150 l/min

- coolant pump power: 0.73 kW

- noise level: 74 dB(A)

- dimensions including chip conveyor (L x W x H): 4000 x 1900 x 1850 mm

- weight of the BIGLIA B658 machine including chip conveyor: 6000 kg

Equipment of BIGLIA turning center

- CNC control: FANUC Series 21i-TB

- automatic tailstock

- bi-directional 12-position turret

- chip conveyor

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe