BIZETA BZ3T4P/8 welding machine was built in Italy in 1989. The machine is designed to perform a very precise and accurate welding of materials such as PVC and polyester by subjecting the surface of the material to high-frequency energy. Electricity in the form of an electromagnetic field generates heat, which softens the material and fuses its layers together. At the end of the process, the BZ3T4P/8 welding machine with rotary table cools the material surface while holding it under a high pressure, resulting in the formation of a very strong weld. The total weight of the machine is 3400 kg.

Technical parameters of the high frequency welding machine BIZETA BZ3T4P/8

- maximum welding force: 9000 kg

- maximum punching force: 3000 kg

- power: 22 kW

- nominal operating frequency: 27.12 MHz

- maximum electrode power efficiency at high frequency: 10 kW

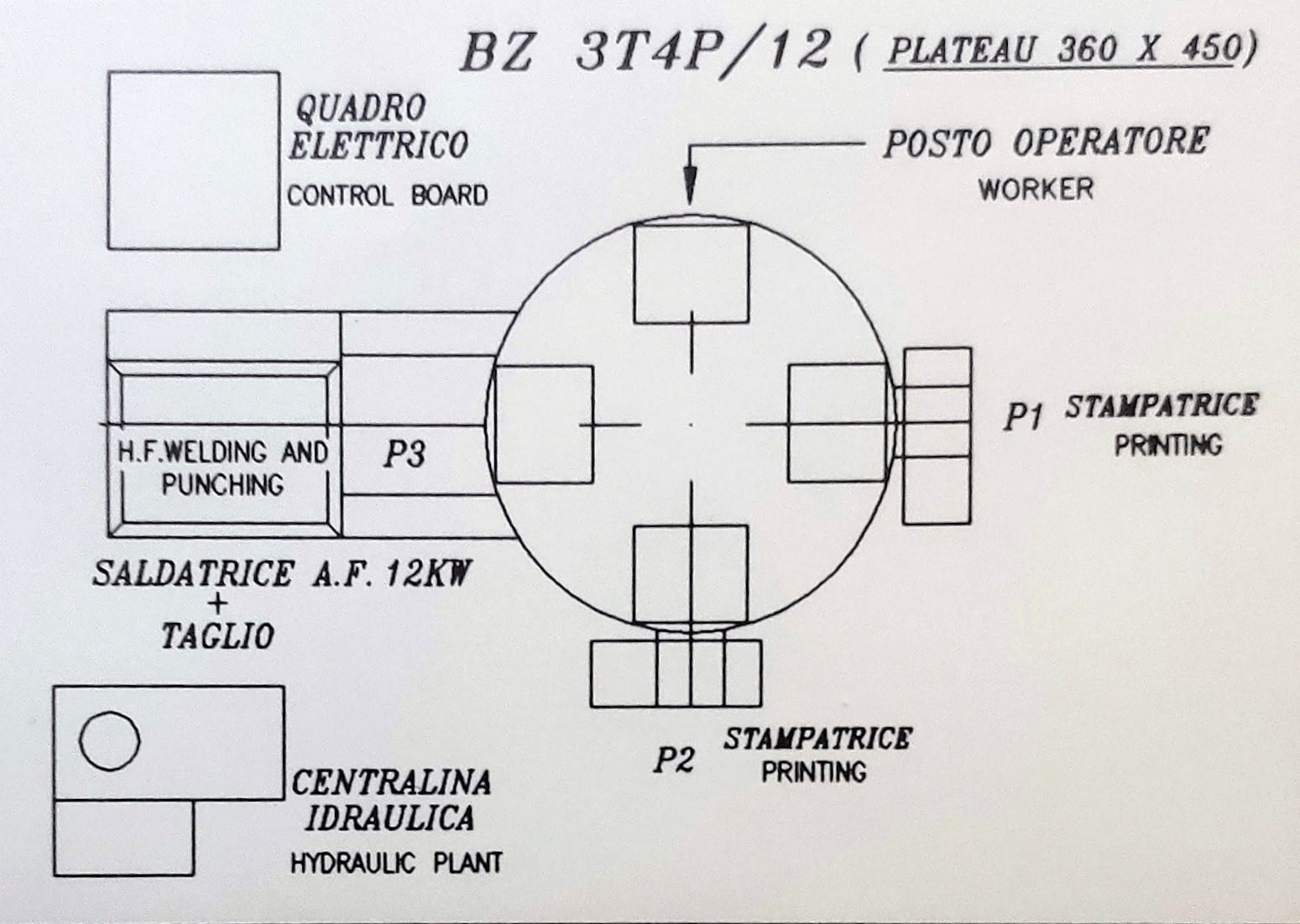

- number of work heads: 3, including:

- output (number of strokes): 430/h

- number of stations on the rotary table: 4

- dimensions of electrode holder (L x W): 360 x 450 mm

- maximum operating pressure: 160 bar

- air pressure: 6 bar

- air consumption at maximum output: 10 l/min

- superposed circuits voltage: 110 V

- maximum power absorbed by the supply line: 25 kW

- power supply: 3x 380 V; 50 Hz

- weight of the BZ3T4P/8 machine: 3400 kg

– head for pattern firing using the high-frequency technique with the possibility of simultaneous shape punching

– head for pattern firing using the hot stamping technique with the possibility of shape punching

– print head for printing in three colours with the use of a thermal printing tape

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe