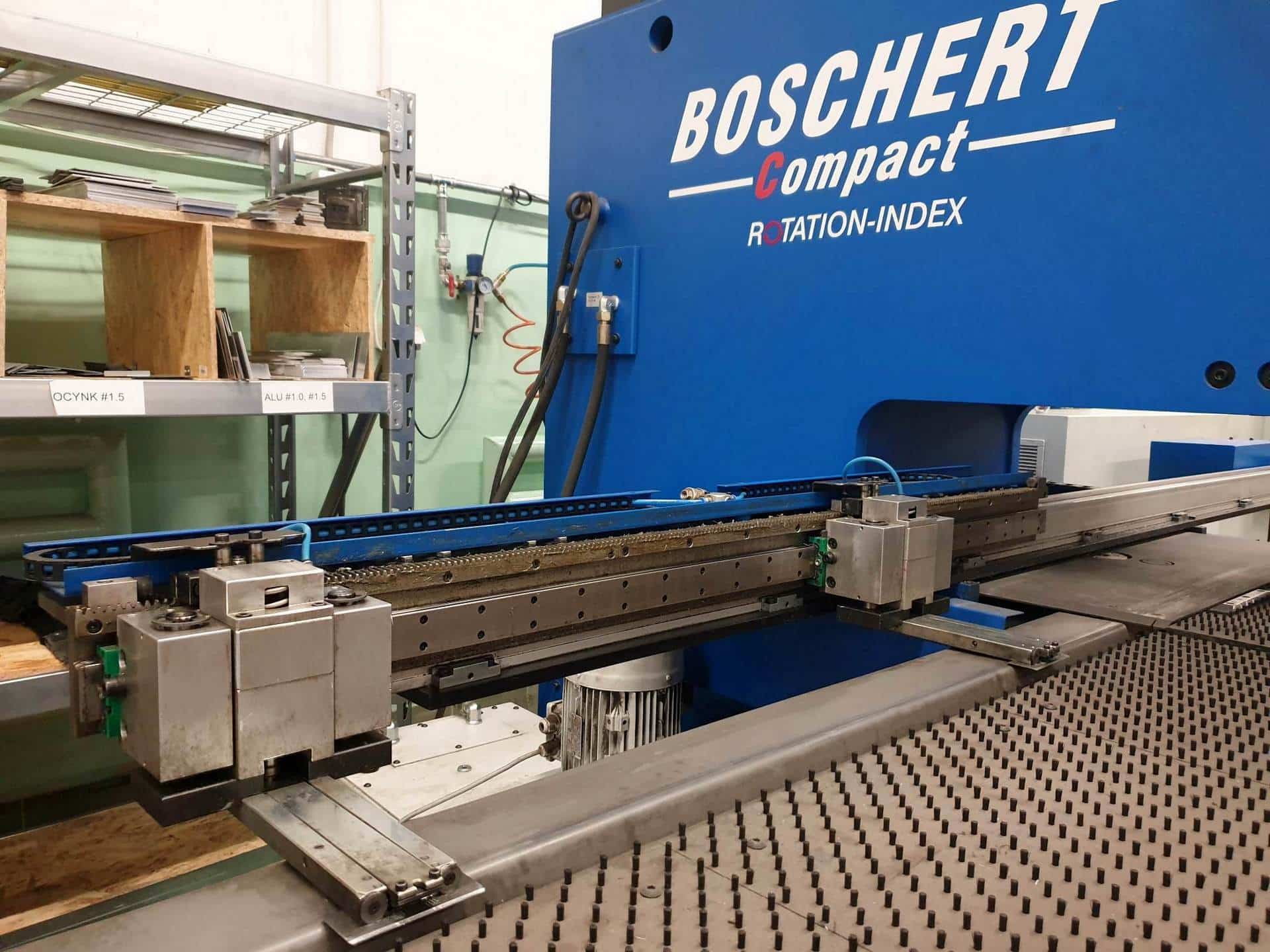

BOSCHERT COMPACT 750 ROTATION punching machine was built in Germany in 2015. A machine with compact dimensions and design is used for precise nibbling, punching and stamping of sheet metal up to 6 mm thick with a force of 28 tonnes. High stability and rigidity are maintained even during demanding series machining.

The BOSCHERT COMPACT 750 X 2000 CNC punching machine is controlled by a modern LABOD CNC control, which allows machining of workpieces with larger dimensions than the basic working range of the X and Y axes in the most optimal way. The possibility of rotating the sheet in relation to the Y axis is determined by a special function used in the control, which then performs automatic repositioning of the workpiece along the X axis. To guarantee high accuracy during repositioning, the sheet is immobilised on the machine table by two hold-downs that prevent the workpiece from moving.

Fast and trouble-free punching of even the most complex shapes is ensured by the single-station rotary head with drive of the ROTATION tooling station, which allows smooth 360° rotation of any tool. The machine also allows automatic creation of machining programmes and simulation of the punching process with selection of appropriate tools, performed by external CNC/KAD METALIX software with the possibility of importing files from other CAD/CAM programmes.

Among the extensive equipment of the BOSCHERT COMPACT ROTATION INDEX hydraulic punching machine are e.g. the TRUMPF quick tool-change system with the possibility of justifying individual tools in any position, a brush table and the BOSCHERT REVOTOOL system with punch and die holder. The total weight of the machine is 7500 kg.

Technical data of the BOSCHERT COMPACT 750 ROTATION punching machine

- maximum press force: 28 t (280 kN)

- maximum workpiece thickness: 6 mm

- number of strokes (nibbling mode 0.1 mm): 280/min

- number of strokes (nibbling mode 1 mm): 500/min

- feed rates in the X/Y axis: 2000/810 mm

- stepless adjustment of feed rates

- sheet repositioning system along the X axis

- possibility of manual axis control

- maximum punching diameter: 105 mm

- maximum number of rotary station tools: 6 pcs.

- tool diameter in rotary station: fi 20 mm

- tool change time: 10-15 s

- maximum stroke height: 90 mm

- frame reach: 810 mm

- precision of bumper positioning: ± 0,1 mm

- oil tank capacity: 115 l

- average power consumption: 4.8 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 3532 x 2600 x 2020 mm

- weight of machine COMPACT 750 ROTATION: 7500 kg

Equipment of the punching machine

- CNC control: LABOD

- CNC/KAD software: METALIX

- quick tool change system: TRUMPF

- ROTATION drive for stepless tool rotation in the tool head

- BOSCHERT REVOTOOL drive including toolholder for punches and dies

- MULTITALK module with additional program memory with USB and LAN interfaces

- tools

- brush table

- extraction device to remove waste material during punching

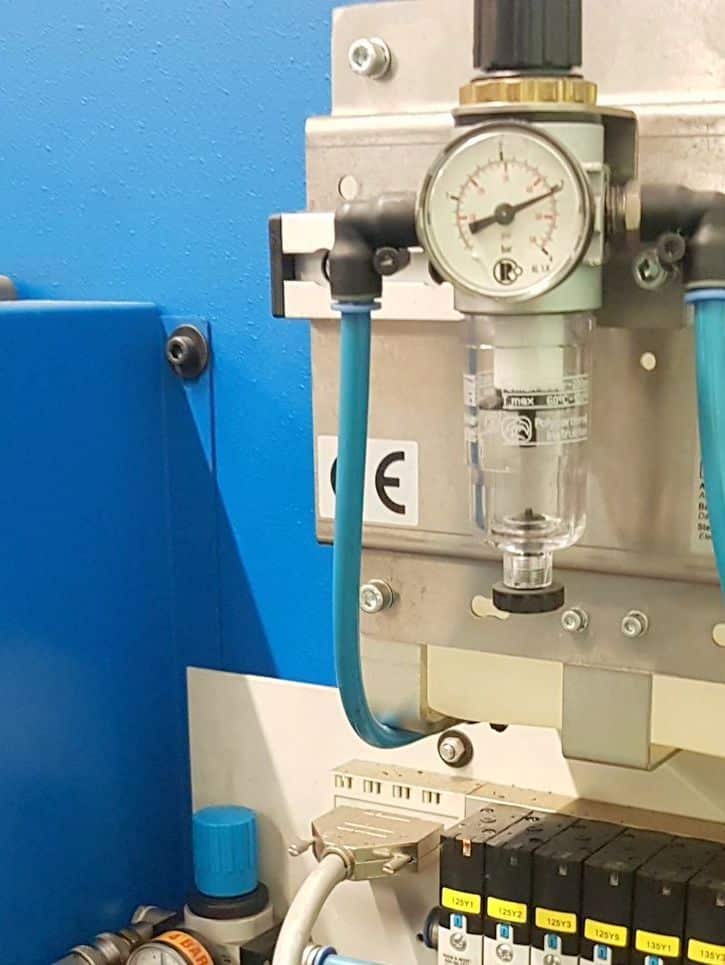

- spraying device

- quick-action holders for single dies for the rotary head (2 pcs)

- hold-downs for holding and moving the sheet (2 pieces)

- automatic positioning of sheet hold-downs

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe