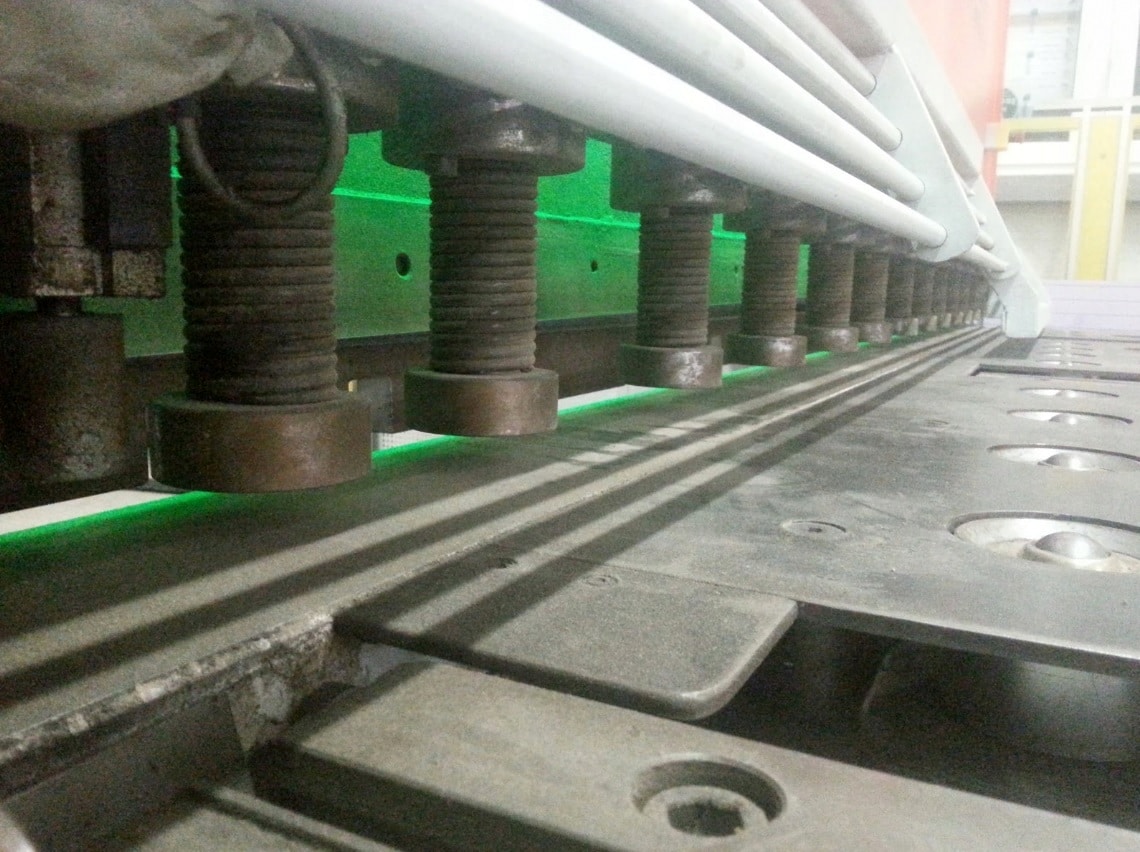

BOSCHERT G CUT 2504 CNC guillotine shears were manufactured in 2014 in Germany. The guillotine is designed for cutting metal sheets with a maximum length of 2600 mm and a thickness of 4 mm (mild steel st42) or 2 mm (stainless steel). The sheet metal is held in place by 13 hydraulic clamps and, thanks to the installed CNC controller with touch panel, it is also possible to store many different work programmes, making the machine very useful and versatile.

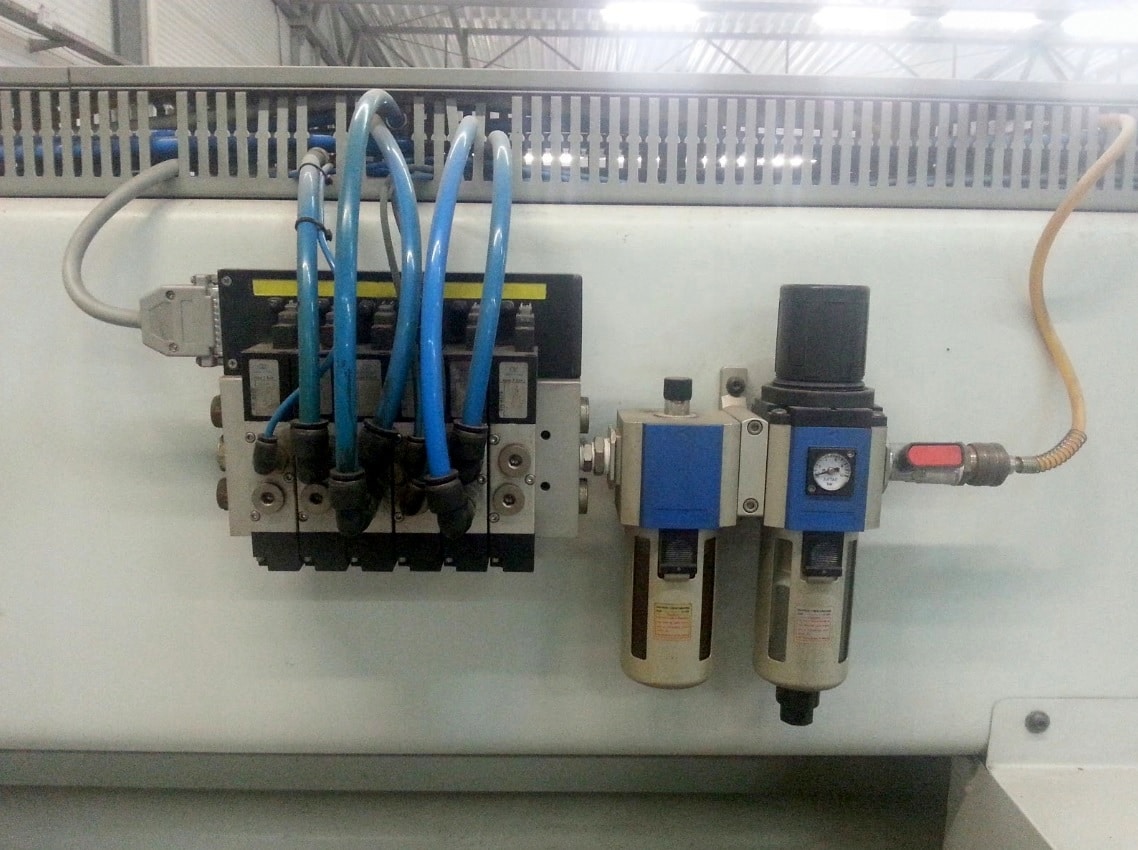

After entering the parameters of the steel sheet to be cut, the controller automatically sets the cutting gap, selects the angle of the upper knife and the appropriate pressure force and then starts the cutting process. The guillotine is also equipped with, among other things: a foot control to facilitate the operator’s work, light curtains to prevent a worker from entering the working area of the machine and an automatic metal sheet thickness measurement. The main advantage of the guillotine is its short working time. The total weight of the guillotine shears is 5200 kg.

Technical data of hydraulic guillotine shears BOSCHERT G CUT 2504 CNC

- CNC control with touch panel

- maximum cutting length: 2600 mm

- maximum cutting thickness of mild steel st42: 4 mm

- maximum cutting thickness of stainless steel: 2 mm

- cutting angle: 1.26°

- rear bumper stroke: 1000 mm

- automatic support table

- automatic sheet thickness measurement

- hydraulic clamps holding the workpiece: 13 pcs

- illuminated cutting line

- foot controller

- light curtains

- maximum hydraulic pressure: 255 bar

- main motor power: 7.5 kW

- power supply: 3 x 400 V, 3 phases, 50 Hz

- machine dimensions (L x W x H): 2940 x 3470 x 1710 mm

- total weight: 5200 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe