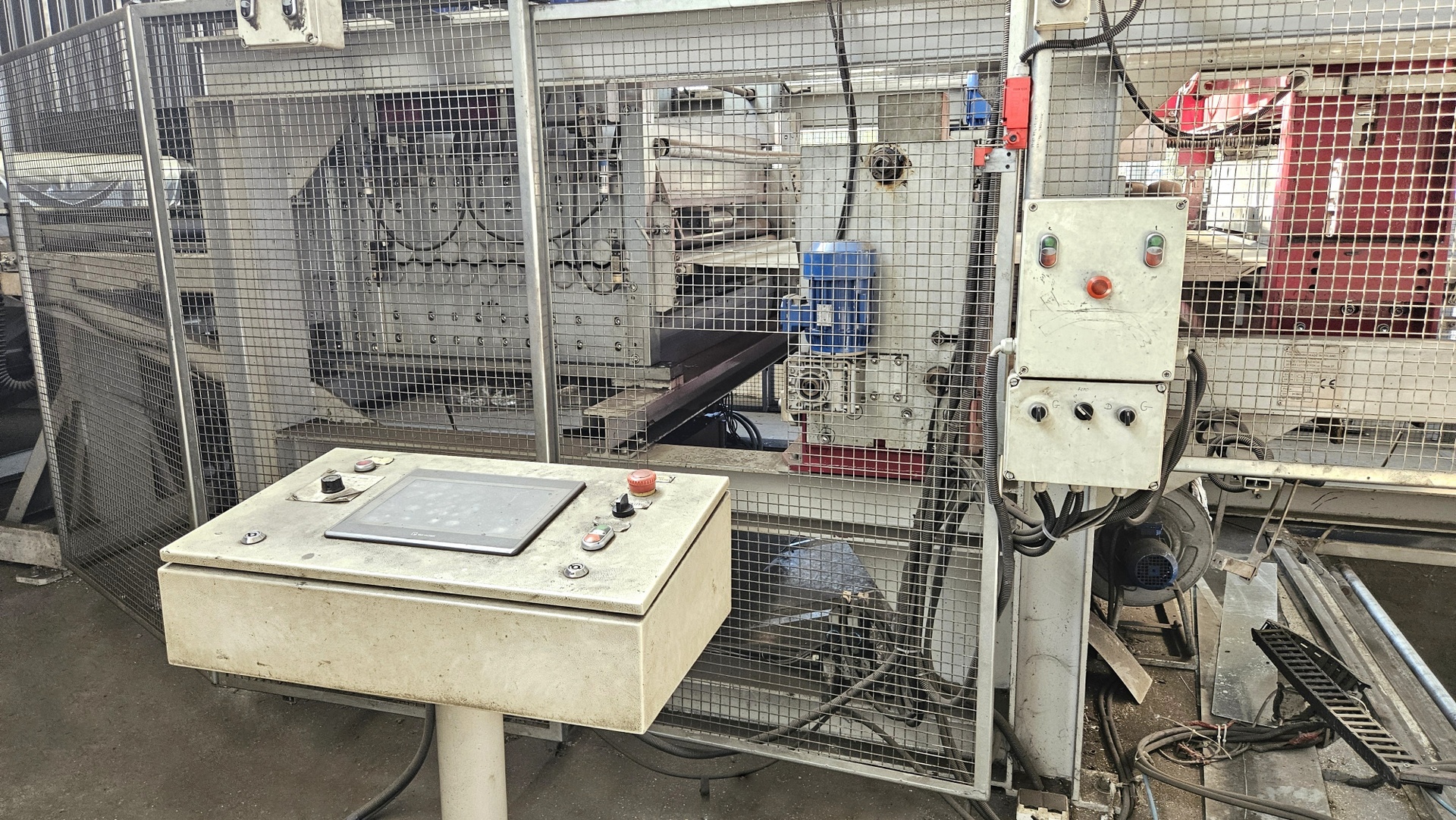

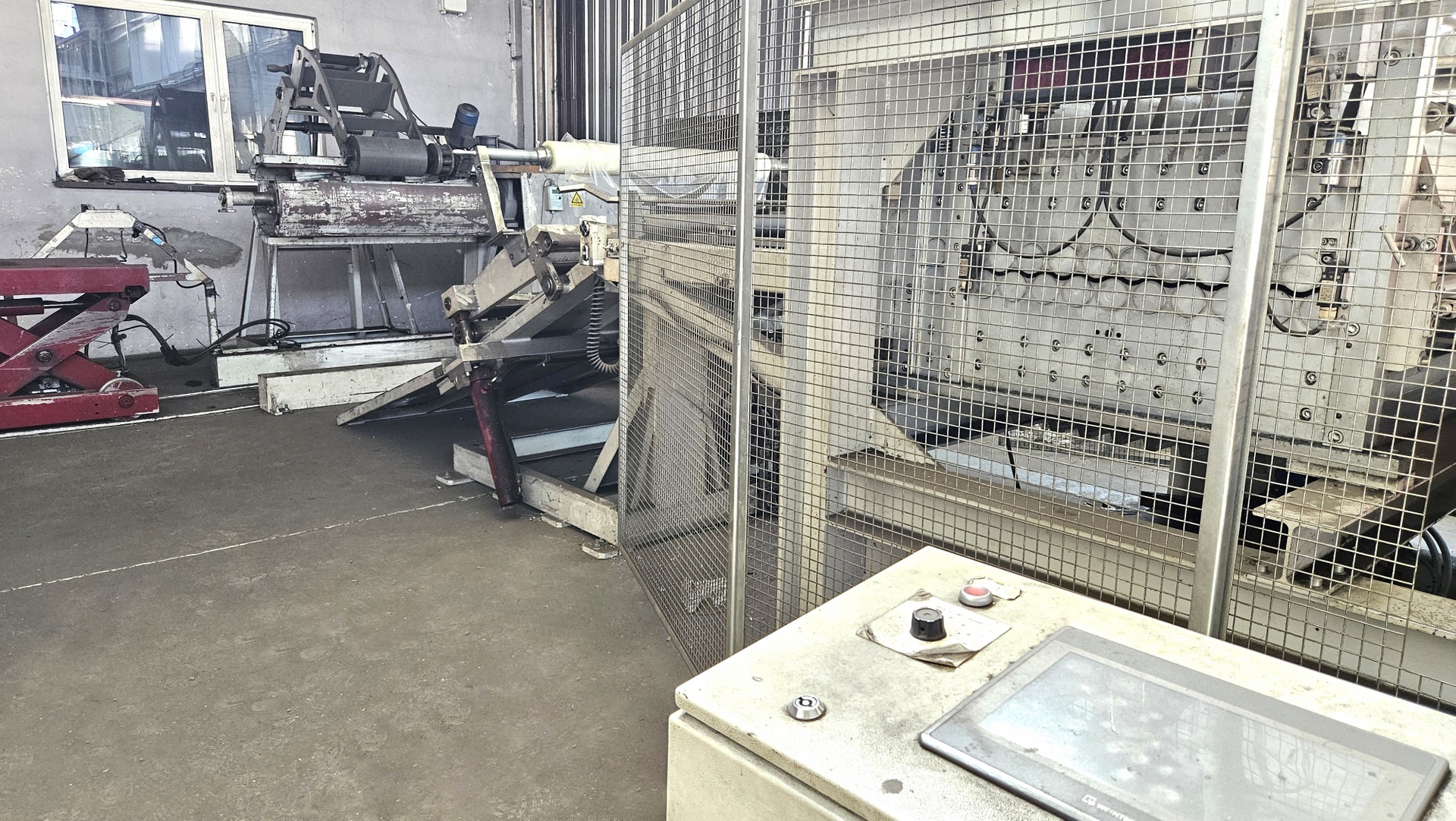

BUD-MASZ slitting and cut-to-length line was built in 2011 in Poland by P.W. BUD-MASZ MACIEJ STACHLEWSKI. The system enables the precise cutting of material with a maximum thickness of 2.5 mm into both sheets and strips of equal width. The entire process is performed fully automatically. The material is uncoiled gradually towards the workspace, inside which there are, among others, high-quality roller knives and a transverse guillotine. The use of these components guarantees the highest cutting precision with optimum utilisation of the raw material. Once the cycle is complete, the sheets are taken out of the workspace by means of a lift table. In the case of slitting, the finished strips of material are wound back onto the coils. All this makes the offered BUD-MASZ slitting and cut-to-length line the best choice for any industrial plant.

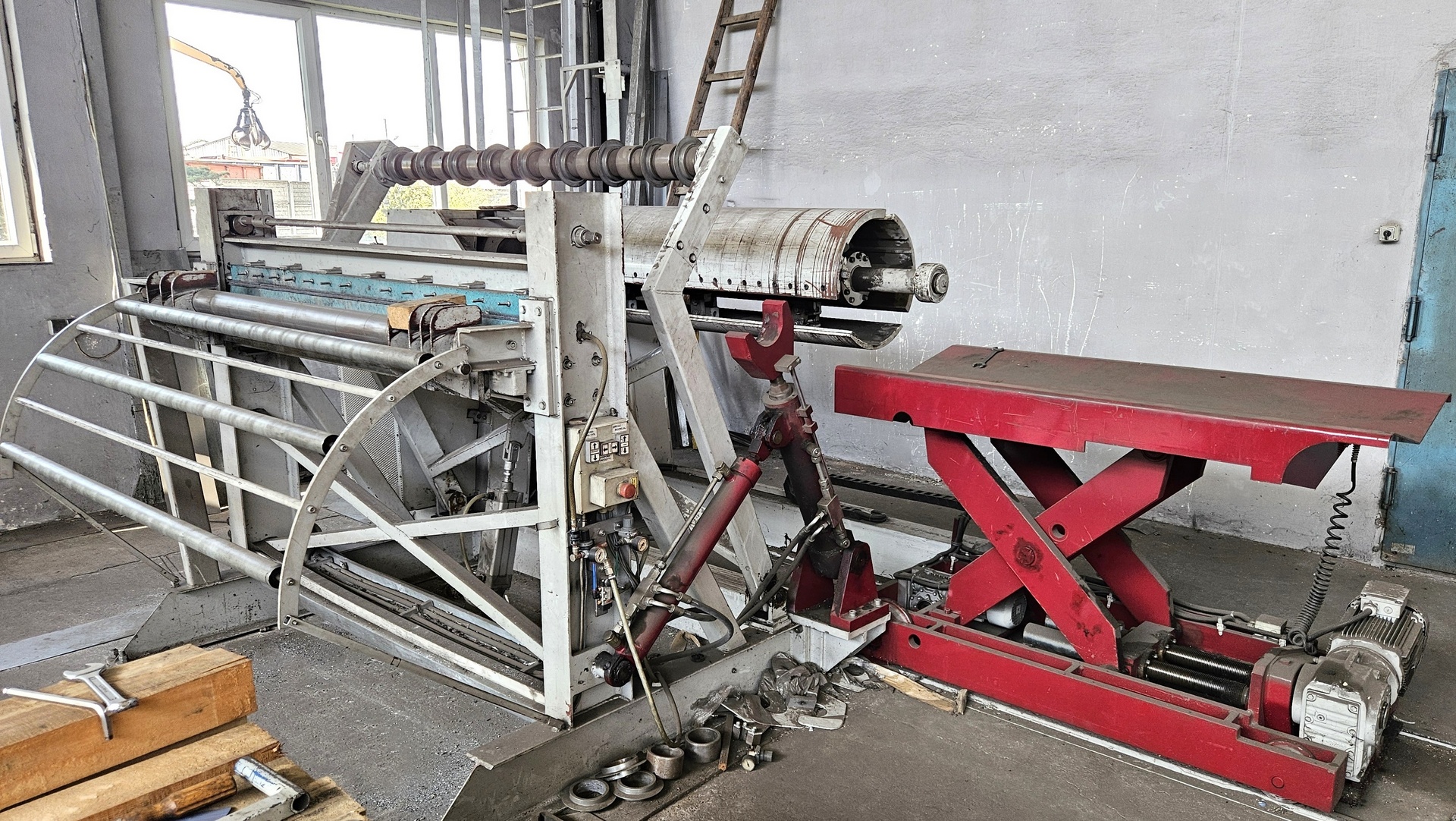

The coil slitting line is fully complete and consists of the following components:

1. hydraulic sheet metal decoiler 10 t

2. coil lift table 10 t

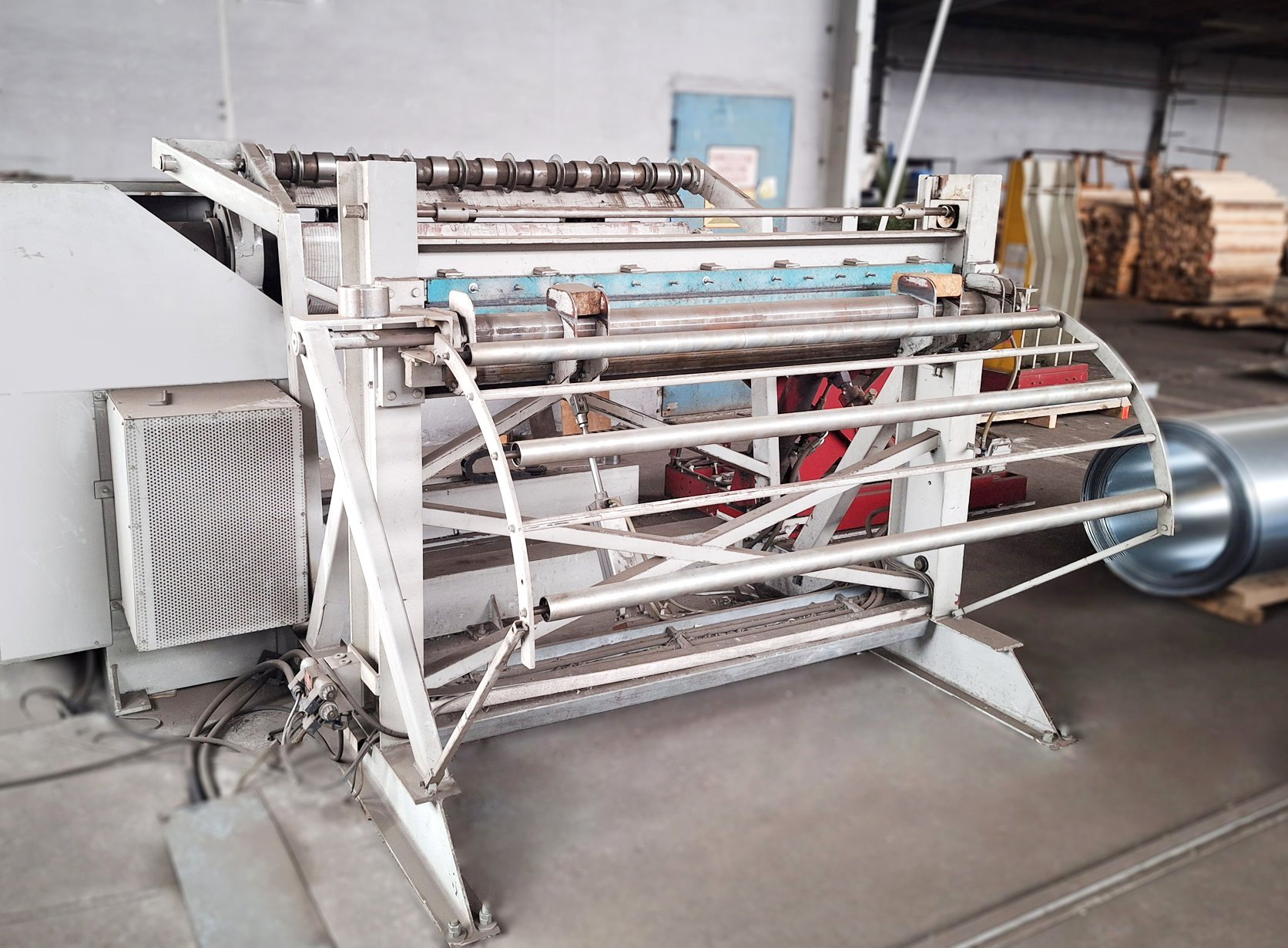

3. infeed module for guiding material of different widths

4. foiling system

5. sheet metal straightening machine

6. roller knives

7. transverse guillotine

8. hydraulic receiving table with buffers

9. waste recoiler

10. mechanical recoiler of cut strips with separators and lifting trolley for removing cut material and hydraulic support of shaft end

Technical specifications of BUD-MASZ slitting and cut-to-length line

General data

- maximum cutting thickness (cut-to-length): 2.5 mm

- maximum cutting thickness (slitting): 2 mm

- maximum cutting width (cut-to-length): 1550 mm

- minimum cutting width (slitting): 90 mm

- maximum coil weight: 10 t

- power supply of BUD-MASZ slitting line: 3x 380 V; 50/60 Hz

Hydraulic sheet metal decoiler

- payload: 10000 kg

- pneumatic pressing

- synchronisation of the decoiler drum rotation with the straightening machine

- brake

Coil lift table

- payload: 10000 kg

Infeed module

- material width range: 1600 mm

- adjustment: stepless

- angle bars

Sheet metal straightening machine

- hardened 9/10 straightening rollers

- straightening rollers drive: cardan joints Ø 70 mm

Roller knives

- quantity: 12 pairs

- maximum material thickness: 2 mm

- maximum material width: 1600 mm

Transverse guillotine

- maximum material thickness: 2.5 mm

- maximum material width: 1600 mm

Receiving table with buffers

- maximum material length: 6 m

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe