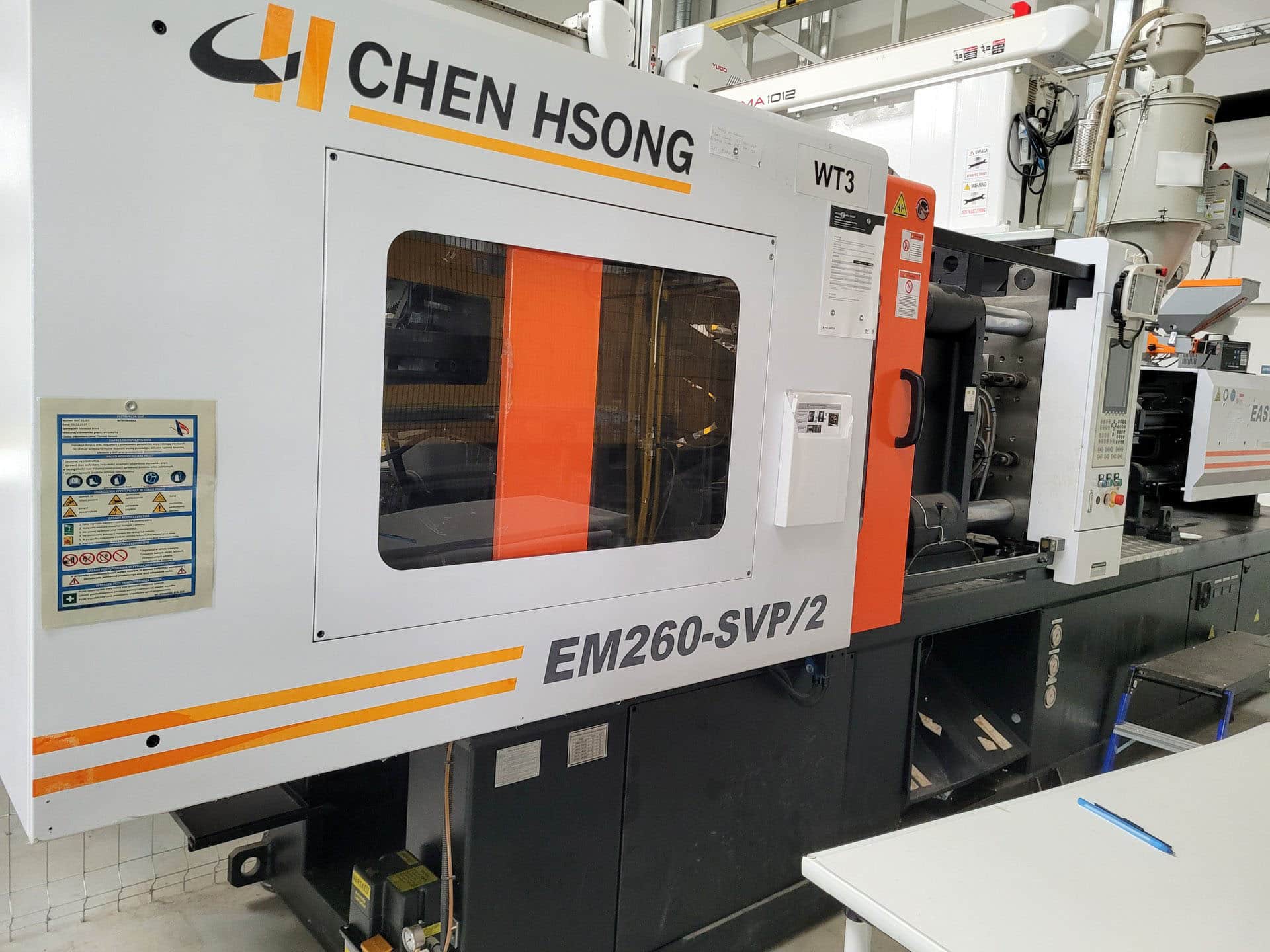

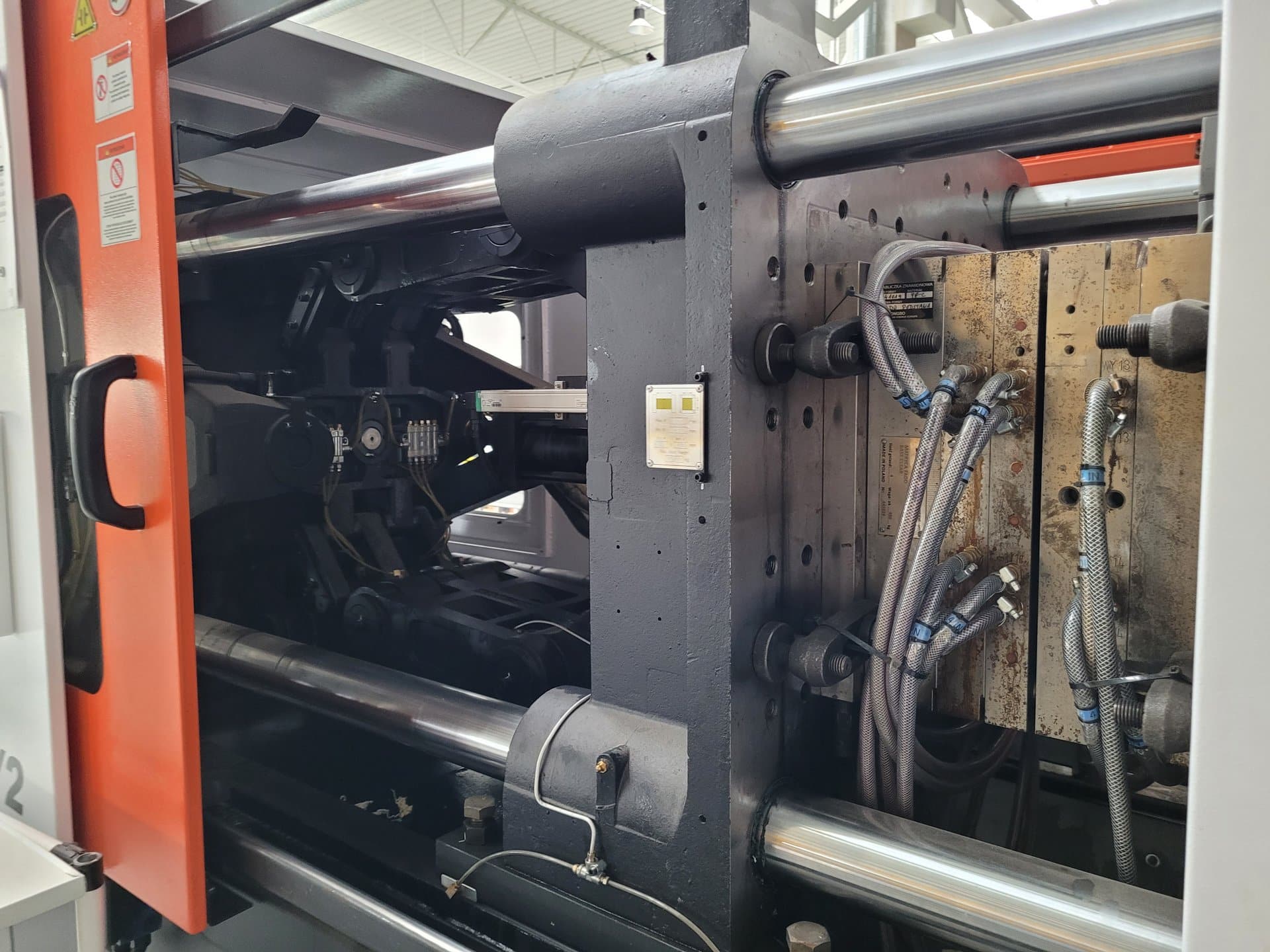

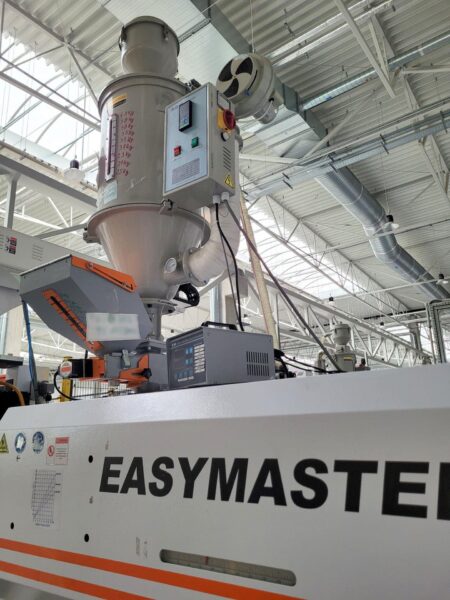

CHEN HSONG EM260-SVP/2 injection moulding machine, designed for the processing of thermoplastics using injection moulding method, was manufactured in China in 2017. The plastic which has sufficient plasticity, is fed into injection moulds mounted on 840 x 840 plates, and then closed with a force of 320 tonnes.

The combination of high clamping force with top-quality components and high injection capacity ensure exploitation of all of the machine’s strengths and maximise the efficiency and productivity of the EM260 SVP2 injection moulding machine. The machine’s special design screw, with a diameter of 52 mm and a high rotational speed of 166 rpm, guarantees excellent product quality while reducing cycle times. The total weight of the CHEN HSONG EM 260 injection moulding machine is 7575 kg.

Technical specifications of the CHEN HSONG EASYMASTER EM260-SVP/2 injection moulding machine

- clamping force: 260 t

- screw diameter: 52 mm

- maximum screw speed: 166 rpm

- screw stroke: 275 mm

- injection weight: 537 g

- injection volume: 584 cm3

- injection capacity: 201 g/s

- injection pressure: 226 MPa

- plasticisation capacity: 31 g/s

- mould plate dimensions (L x W): 840 x 840 mm

- clearance between columns: 580 x 580 mm

- minimum mould thickness: 195 mm

- maximum mould thickness: 600 mm

- maximum mould opening stroke: 535 mm

- ejector stroke: 180 mm

- ejector power: 7,7 t

- number of heating zones: 5+nozzle

- heating power: 18.3 kW

- servomotor

- pump power: 36 kW

- power: 55 kW

- oil tank capacity: 430 l

- working pressure: 17.8 MPa

- voltage: 3x 400 V; 50 Hz

- overall dimensions (L x W x H): 6400 x 1500 x 2200 mm

- total weight of the EM260-SVP/2 machine: 7575 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe