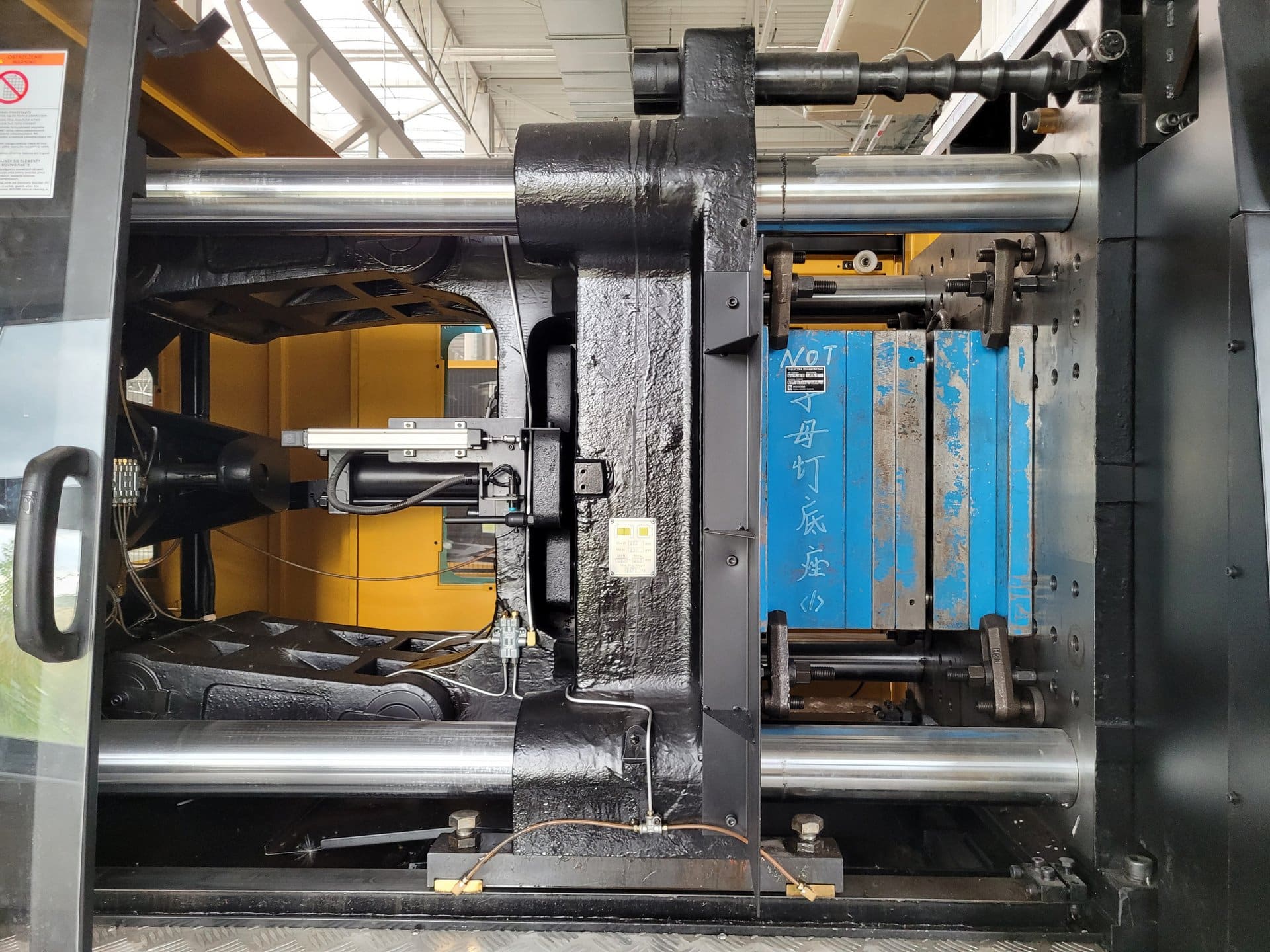

CHEN HSONG EM320-SVP/2 injection moulding machine was built in 2016 in China. The machine is equipped with high-end components to achieve the best quality of manufactured products made of thermoplastics, by using the injection moulding method. The high quality of the manufactured products is especially influenced by the high injection capacity and the 75 mm diameter screw, whose special design significantly reduces cycle time.

Plastic of sufficient plasticity is fed into an injection mould with a thickness of 220 to 600 mm, that is closed with a force of 320 tonnes. The CHEN HSONG EM 320 injection moulding machine offers the highest productivity and efficiency in its class. The total weight of the EM320 SVP2 machine is 11600 kg.

Technical specifications of the CHEN HSONG EASYMASTER EM320-SVP/2 injection moulding machine

- clamping force: 320 t

- screw diameter: 75 mm

- maximum screw speed: 149 rpm

- screw stroke: 320 mm

- injection weight: 1300 g

- injection volume: 1413 cm3

- injection performance: 382 g/s

- injection pressure: 140 MPa

- plasticisation capacity: 65 g/s

- mould plate dimensions (L x W): 940 x 940 mm

- clearance between columns: 660 x 660 mm

- mould opening stroke: 600 mm

- minimum mould thickness: 220 mm

- maximum mould thickness: 660 mm

- ejector stroke: 180 mm

- ejector power: 7,7 t

- servo motor

- number of heating zones: 5+nozzle

- heating power: 19.9 kW

- power: 67 kW

- pump power: 48 kW

- working pressure: 17.8 MPa

- oil tank capacity: 525 l

- voltage: 3x 400 V; 50 Hz

- overall dimensions (L x W x H): 6900 x 1600 x 2300 mm

- total weight of the EM320-SVP/2 machine: 11600 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe