CINCINNATI MAG CFV 1050i CNC machining centre was manufactured in 2011. The milling centre used for precise machining of workpieces, is characterised by a robust steel structure of high quality and reliable components. The milling process is performed on a large work table with a length of 1120 mm and a width of 600 mm by a reliable spindle operating at a maximum speed of 10000 rpm, guaranteeing high precision and significantly reducing process times.

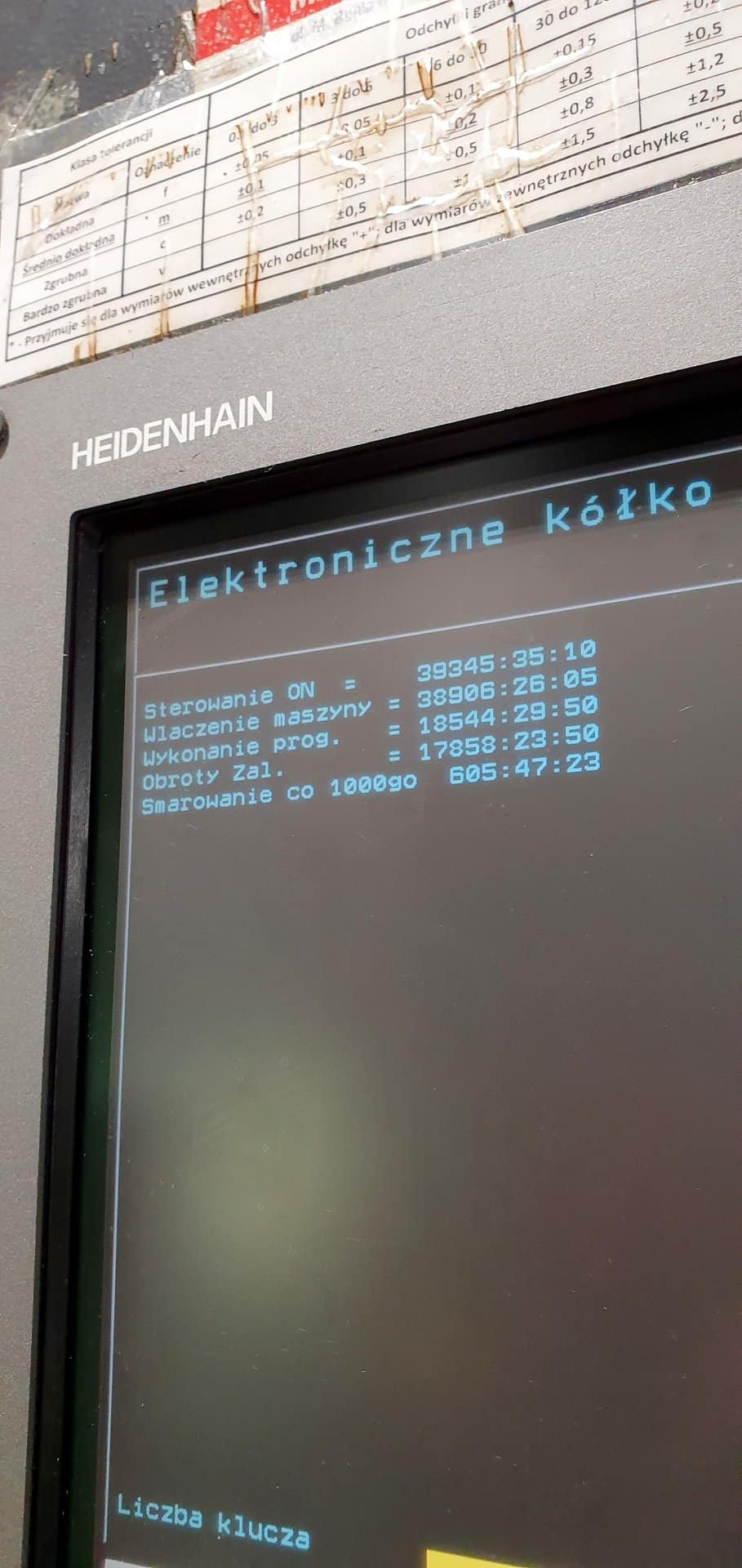

The CINCINNATI CFV-1050i CNC milling centre is offered with a wide range of equipment, including a screw chip conveyor, a control panel with HEIDENHAIN iTNC530 numerical control with the possibility of connecting a fourth axis, and a magazine holding up to 30 tools. The MAG CFV 1050i CNC milling machine weighs 5200 kg.

Technical data of the CINCINNATI MAG CFV 1050i milling centre

- work table surface area (L x W): 1120 x 600 mm

- maximum workpiece weight: 1000 kg

- feed rates in the X/Y/Z axis: 1050/540/720 mm

- rapid traverse in the X/Y/Z axis: 36 m/min

- maximum spindle speed: 10000 rpm

- spindle power: 11 kW

- tool head capacity: 30 pcs.

- maximum tool weight: 6 kg

- maximum tool diameter: 70 mm

- maximum tool length: 300 mm

- number of T-slots: 5

- accuracy of positioning in X/Y axis: ± 3 µm

- accuracy of positioning in Z axis: ± 4 µm

- accuracy of repeatability: ± 1 µm

- maximum machine height: 2750 mm

- space requirement (L x W): 3400 x 3000 mm

- MAG CFV 1050i machine weight: 5200 kg

Equipment of the milling machine

- CNC control: HEIDENHAIN iTNC530

- cooling through spindle (20 bar)

- spindle taper: SK-40

- screw chip conveyor

- possibility to connect a fourth axis to the numerical control

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe