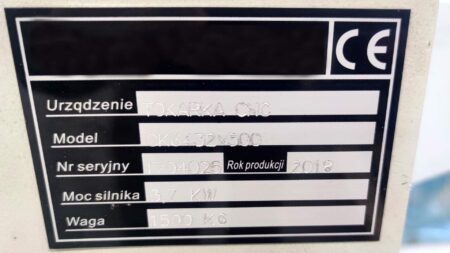

CK6432 X 750 CNC turning center was built in 2018. The machine, designed for machining of rotating workpieces, such as shafts, cones and spheres with a maximum diameter of 360 mm, is distinguished by its extremely high performance and robustness. Inside the large, fully illuminated workspace, there is a bed consisting of two parts with hardened guideways and a cooling system that effectively eliminates any vibrations and oscillations generated during turning. In order to achieve excellent dynamics combined with high feed repeatability, movement in both X and Y axes is realised by a helical gearbox, driven by a servo motor via a synchronous gearbox. The machine’s extensive equipment includes an extremely powerful spindle with an optimised speed range, a hydraulic tailstock and a state-of-the-art SIEMENS CNC control. The CNC lathe CK 6432 weighs 1500 kg.

Technical specifications of the CK6432 X 750 metal lathe

- turning diameter above the bed: 360 mm

- turning diameter over the slide: 150 mm

- maximum turning length: 500 mm

- feed in the X/Z axis: 350/750 mm

- torque in the X/Z axis: 4/7 Nm

- maximum spindle rotational speed: 2500 rpm

- minimum spindle rotational speed: 150 rpm

- spindle bore diameter: 45 mm

- number of tools: 6

- maximum tool size: 16×16 mm

- tailstock sleeve extension: 100 mm

- tailstock sleeve taper: ⌀50 mm/MT4

- guide rail width: 260 mm

- main motor power: 3.7 kW

- coolant pump motor power: 180 W

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 2230 x 1410 x 1990 mm

- weight of machine: 1500 kg

Equipment of the CK6432 lathe

- CNC controller: SIEMENS SINUMERIK 808D

- hydraulic tailstock

- hydraulic chuck

- hydraulic aggregate

- anti-vibration cushions (4 pcs.)

- foot switch control

- DTR – Technical and Operational Documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe