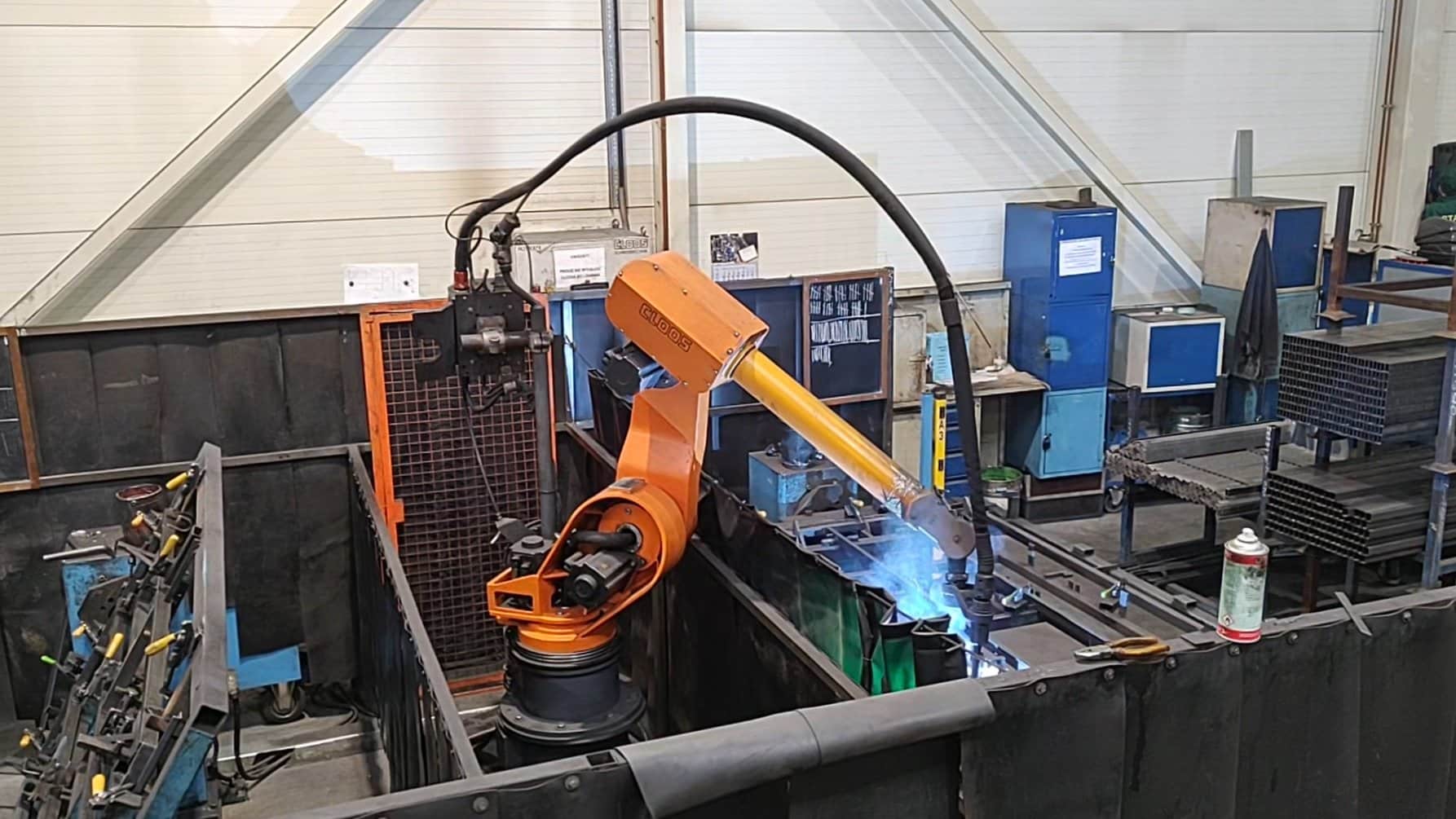

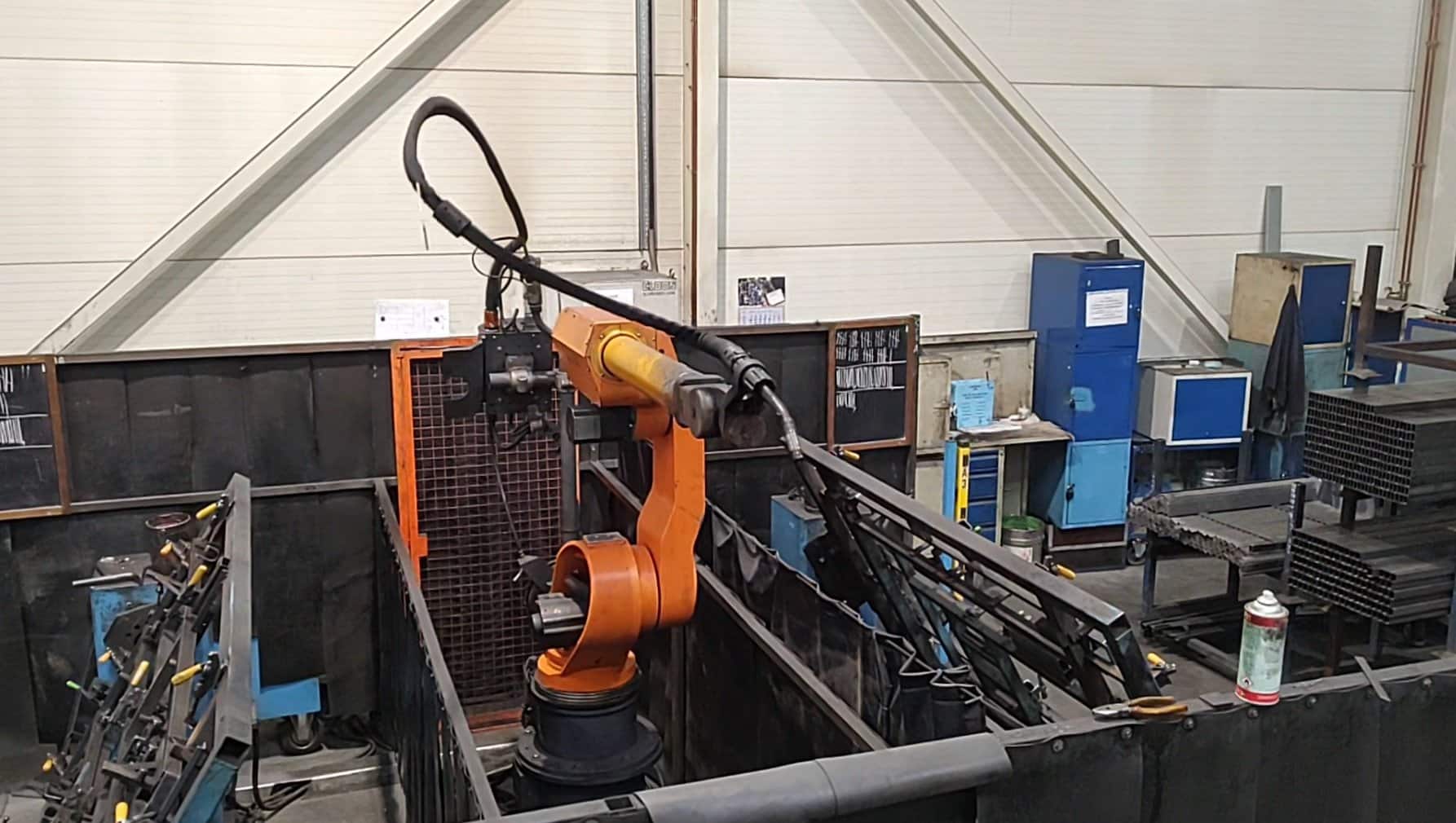

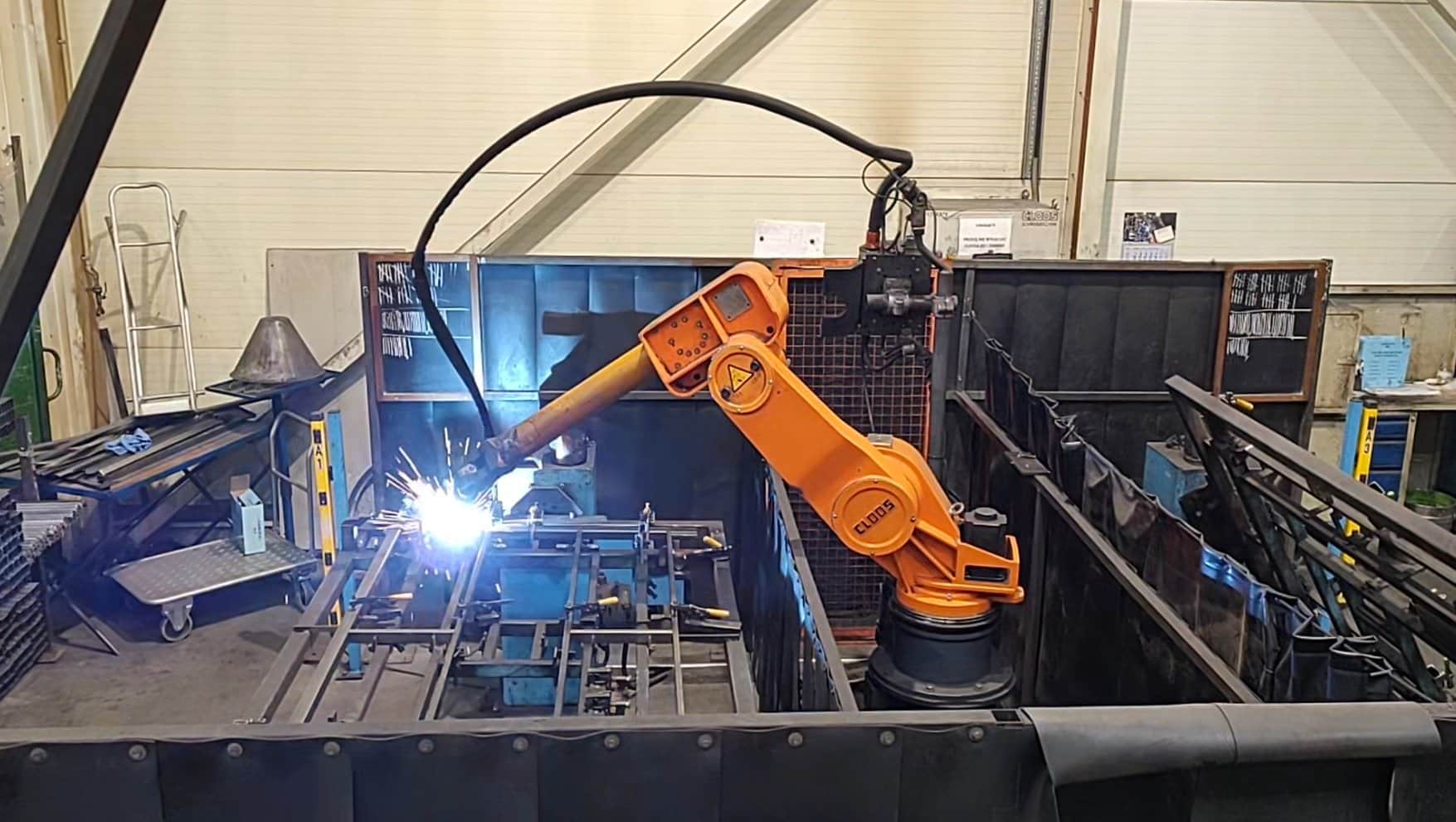

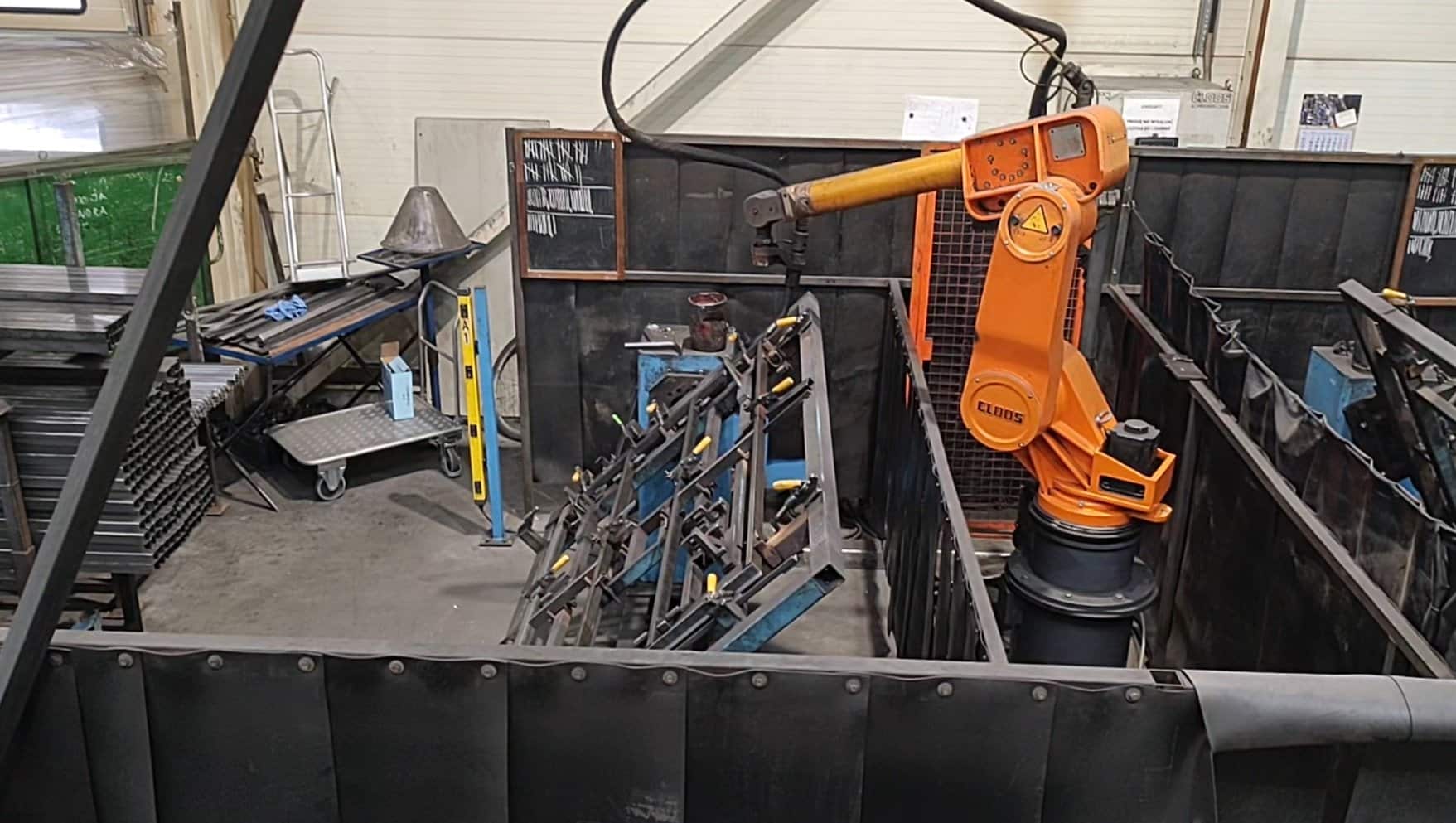

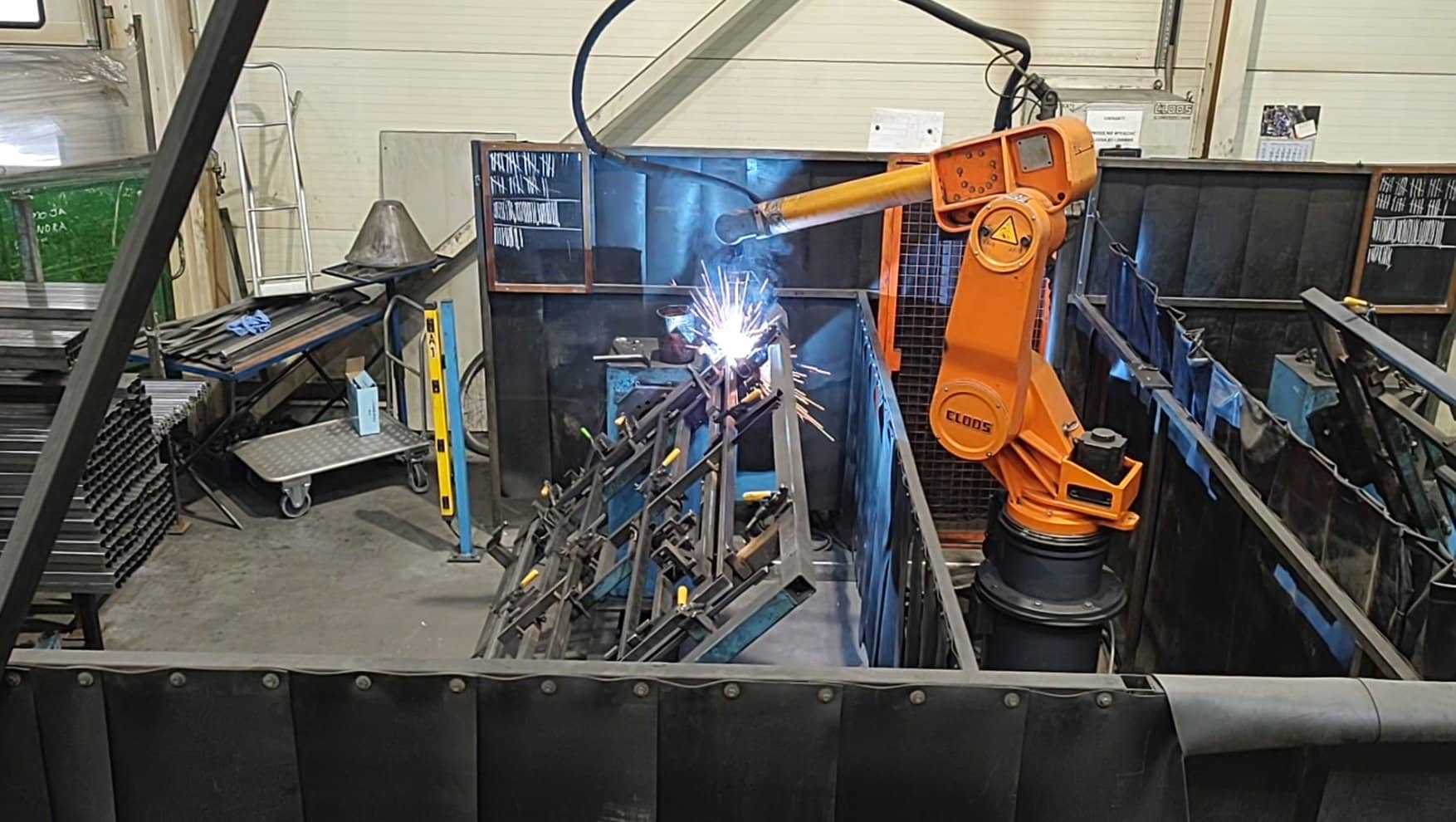

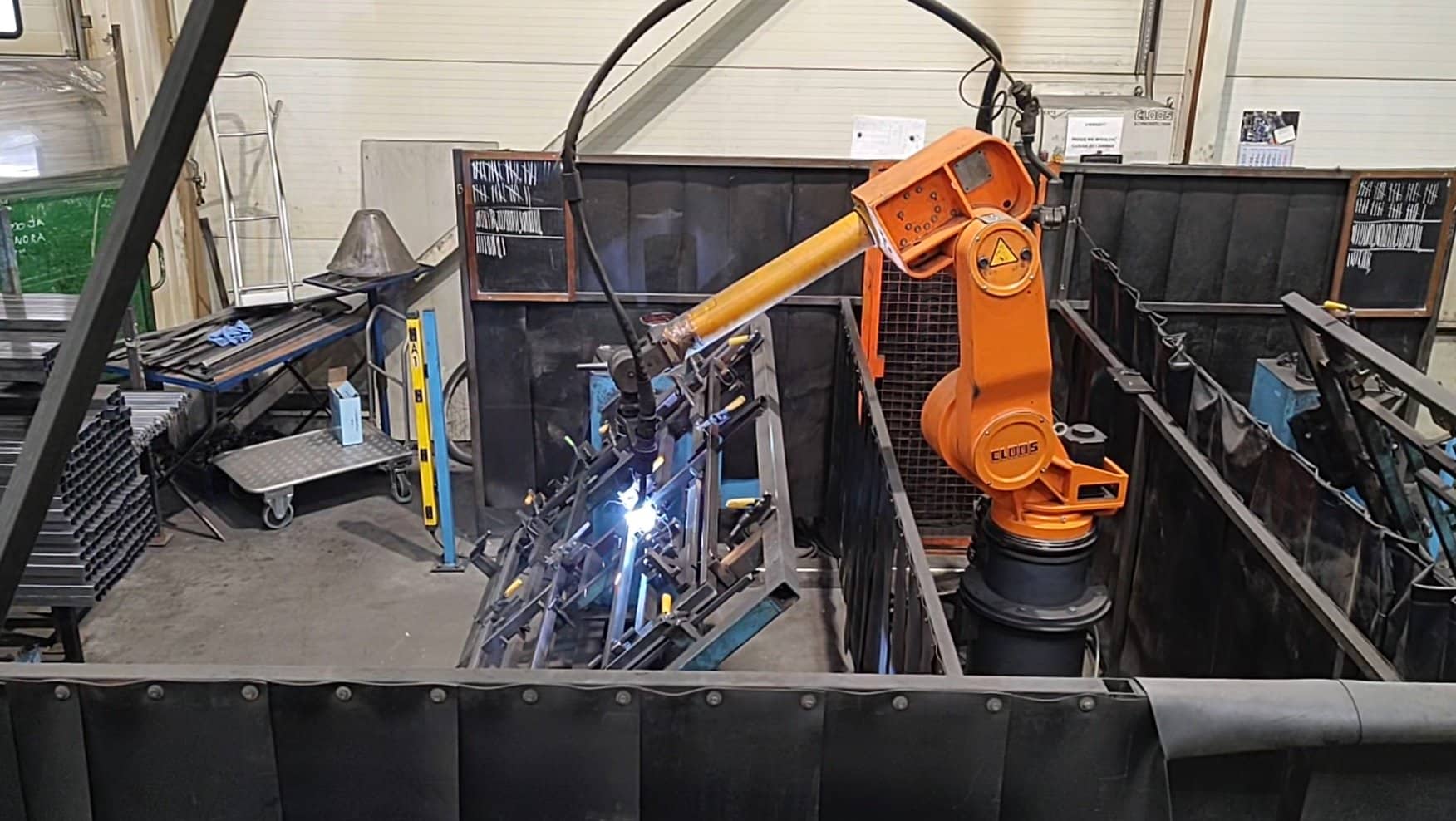

CLOOS ROMAT 410 robotic welding station built in 2007 in Germany, is designed for difficult welding processes using the MAG (135) method. The welding cell is equipped with a special designed industrial robot with high reliability and a modular design, which guarantees efficient operation in all positions at a low operating cost.

The welding robot arm, with a reach of 2500 mm and a load capacity of 10 kg, is driven by dynamic AC servo drives, making possible to achieve high axial speeds necessary for fast movement of any type of workpiece. High repeatability of ± 0.1 mm is achieved through the use of modern compact gears. The robotic welding machine was previously used to weld structures weighing up to 80 kg.

The welding station includes:

– manipulator: CARL CLOOS ROMAT 410

– controller: ROTROL II KOMP

– welding source: CLOOS GLC553 MC3/R

– portable teach pendant: CLOOS PHG

– WPG-S-10000N positioner (2 pcs.) with load capacity of 1000 kg each

– photoelectric barriers (2 pcs.)

– cleaning station: CLOOS CMR-7C

– wire feeder: CK98 A/R 0

– anti-collision connector for mechanical system and welding torch

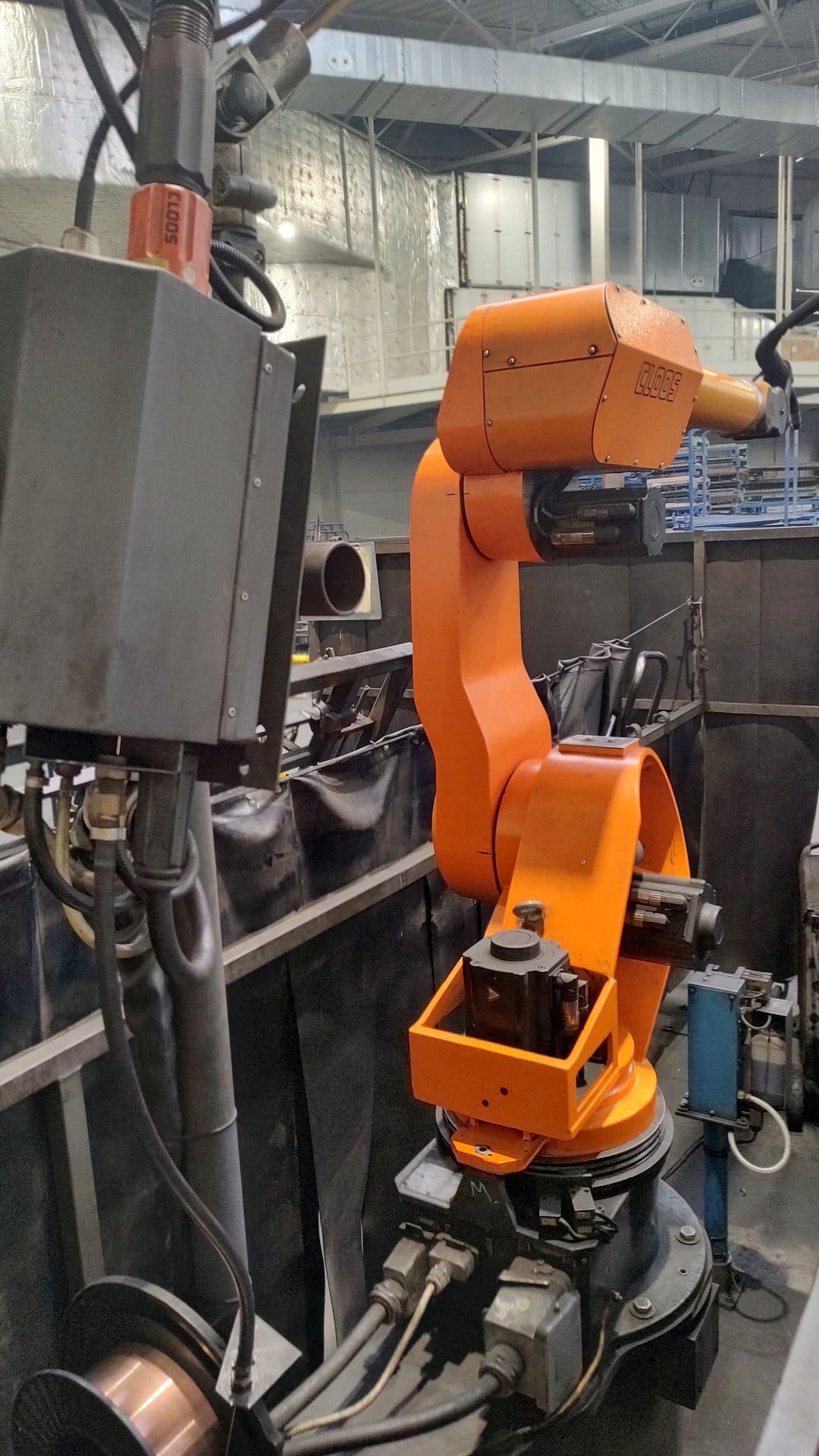

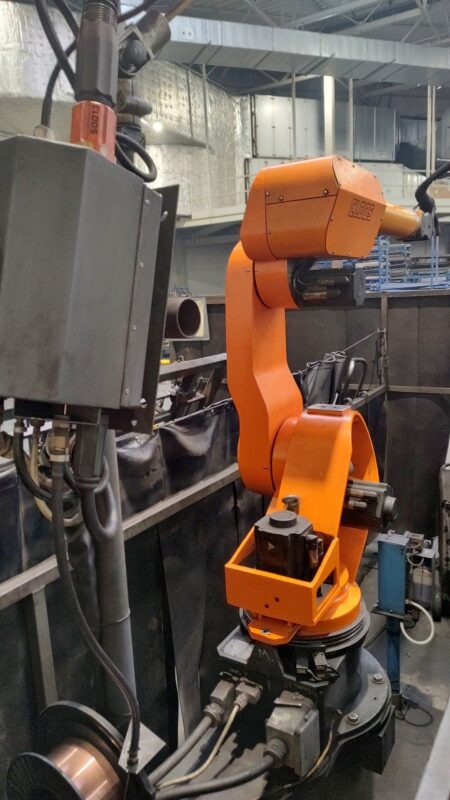

Technical specifications of the CLOOS ROMAT 410 robot

- welding method: MAG (135)

- number of axes: 8

- arm working range: 2500 mm

- arm lifting capacity: 10 kg

- machine axis movement range

- machine axis motion speed

- repeatability: ± 0,1 mm

- height: 2895 mm

- stand dimensions (L x W): 500 x 515 mm

- drive: electronic AC servo motors

- liquid cooling (PETRYGO)

- mounting: floor, wall

- man-hours: 35847 h

- technical documentation

- weight of the ROMAT 410 machine: 205 kg

– axis 1: 340°

– axis 2: 215°

– axis 3: 290°

– axis 4: 358°

– axis 5: 270°

– axis 6: 600°

– axis 1: 151 °/s

– axis 2: 151 °/s

– axis 3: 176 °/s

– axis 4: 290 °/s

– axis 5: 338 °/s

– axis 6: 410 °/s

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe