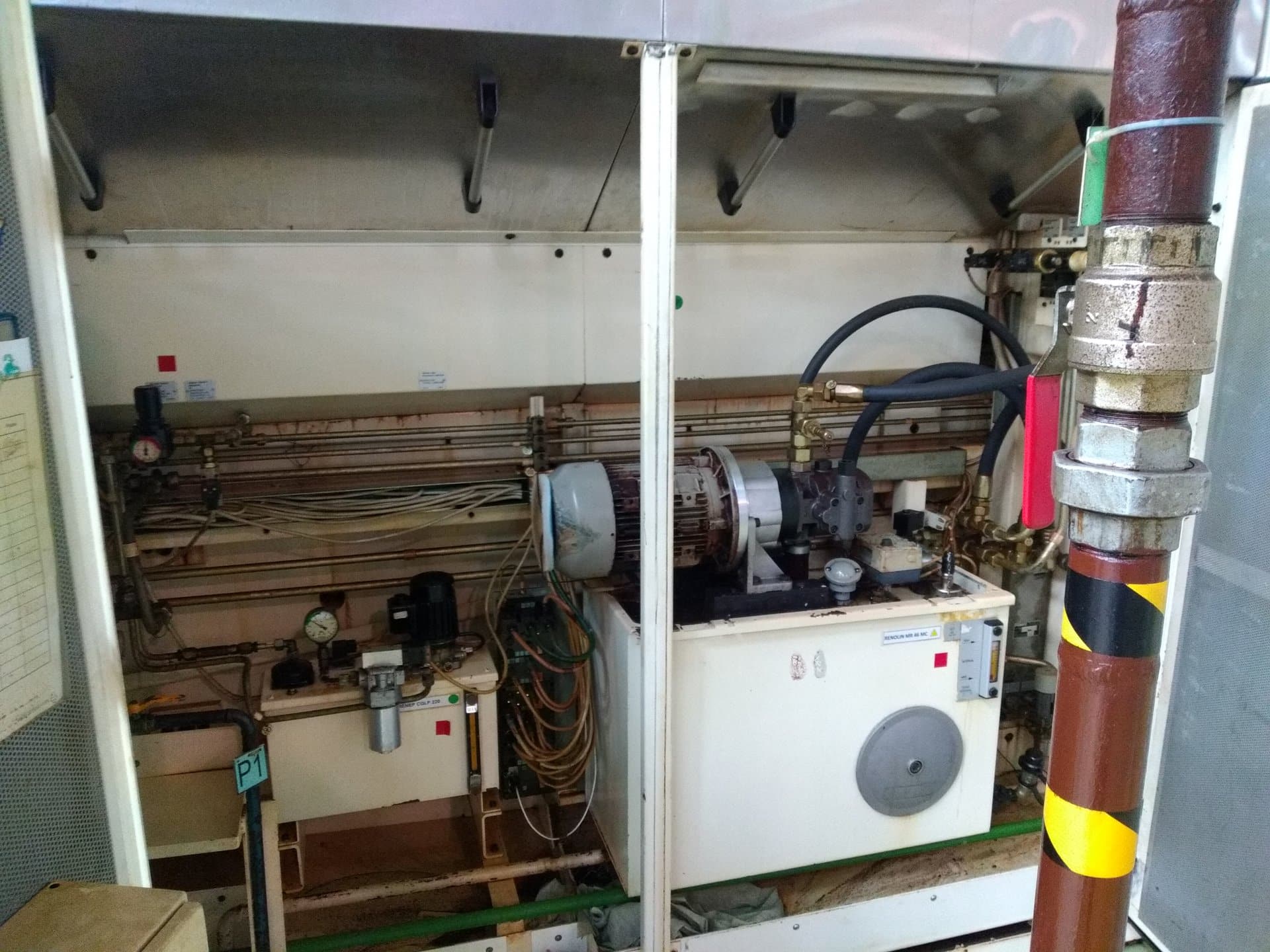

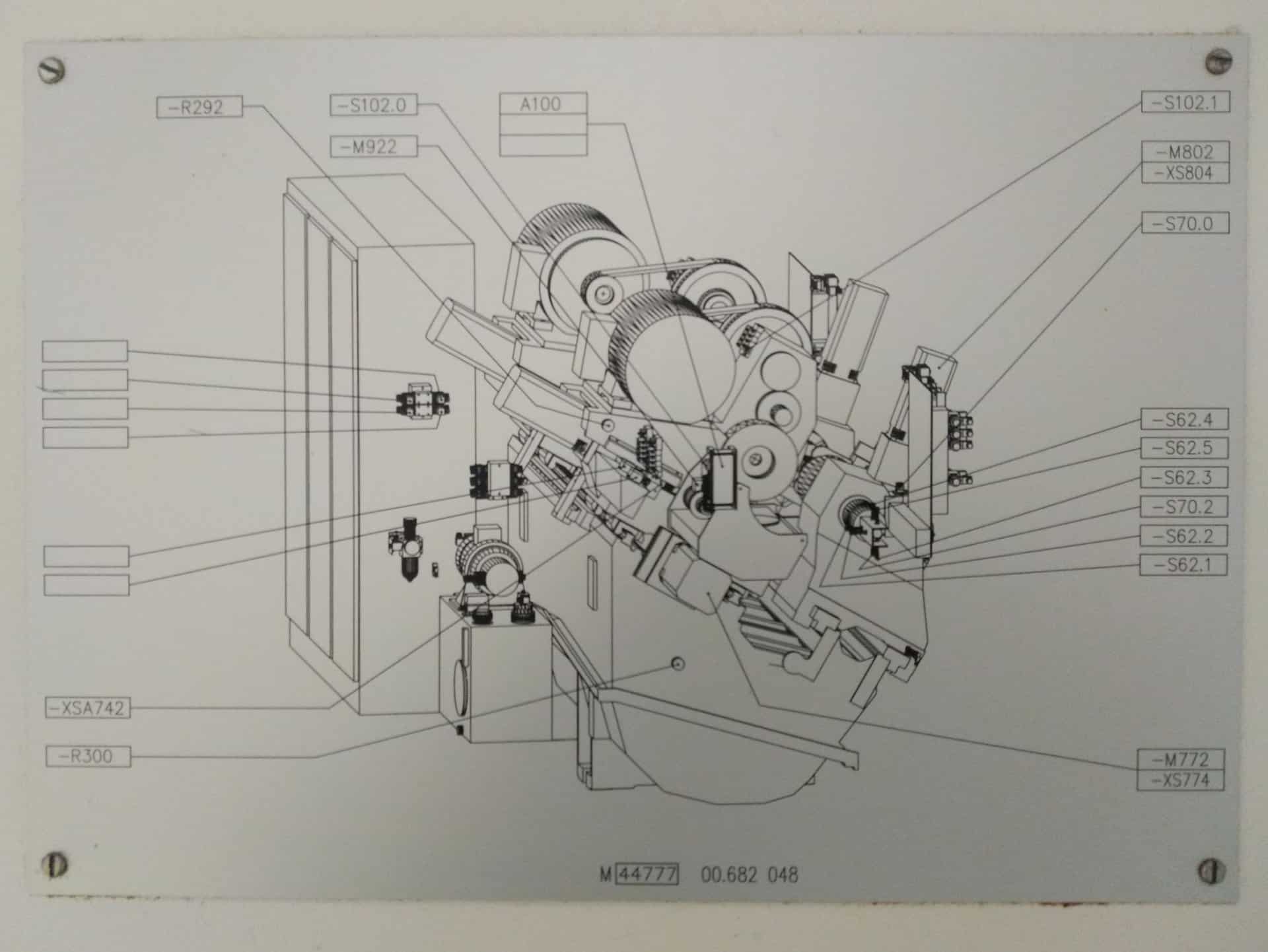

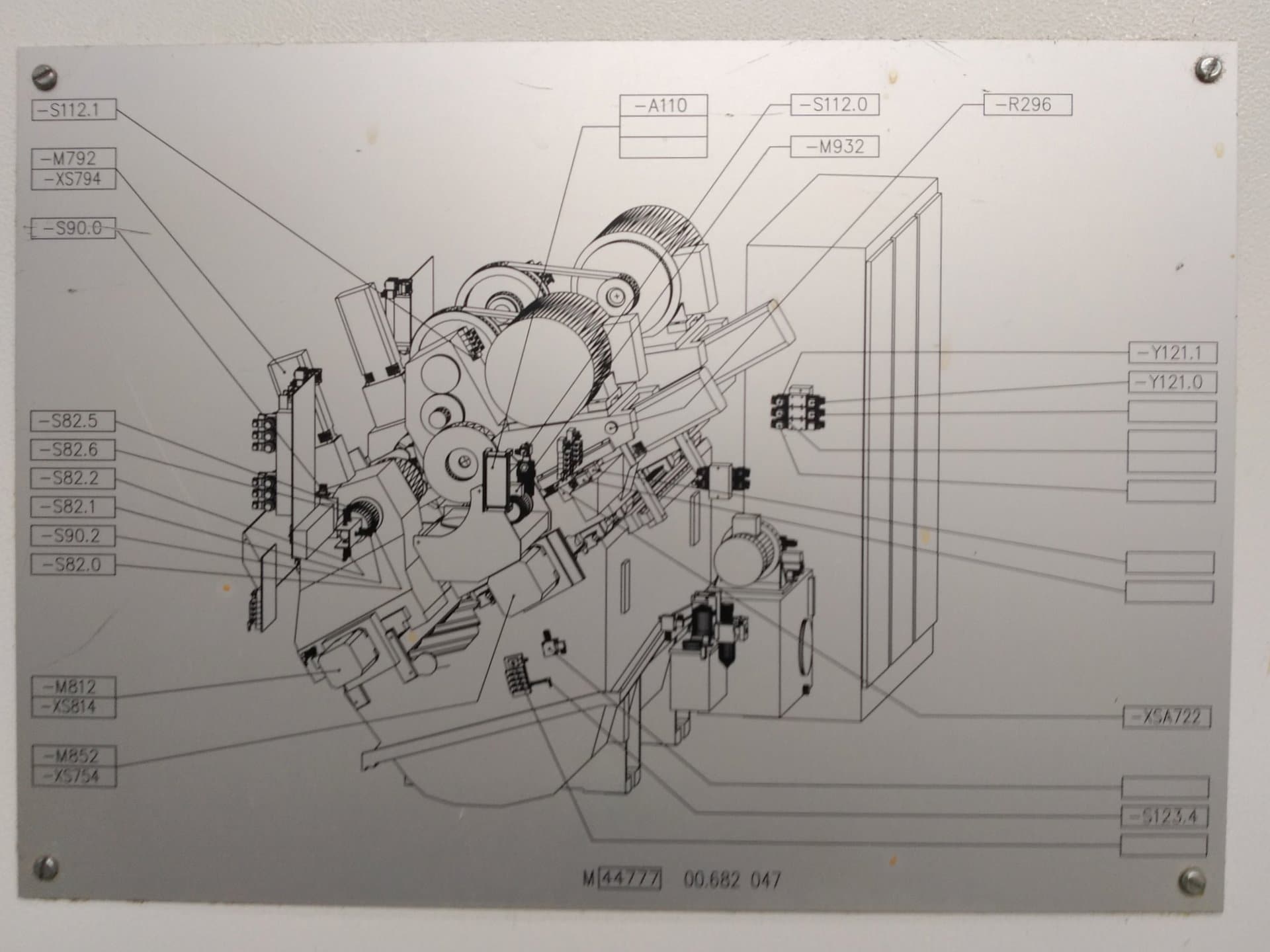

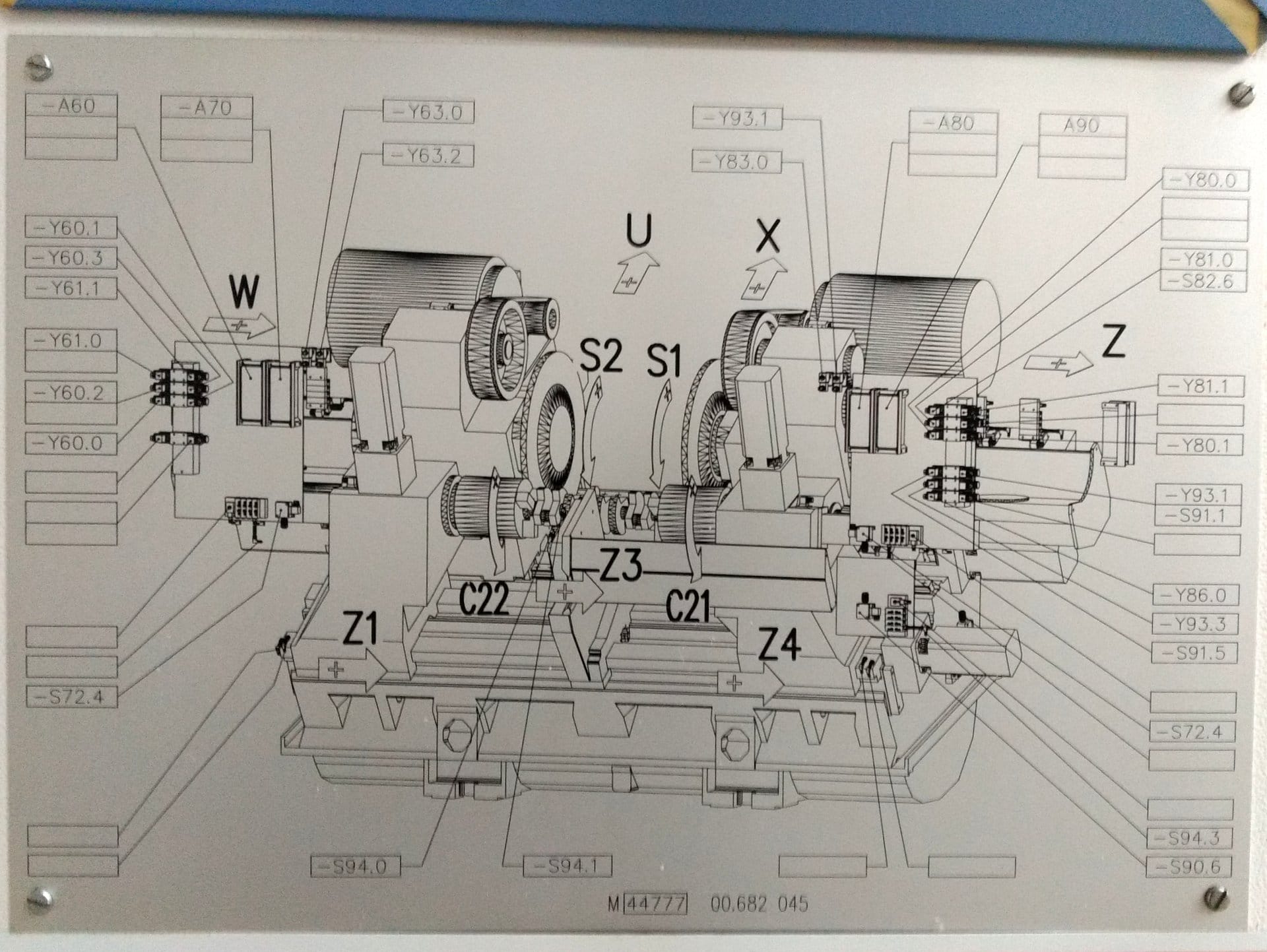

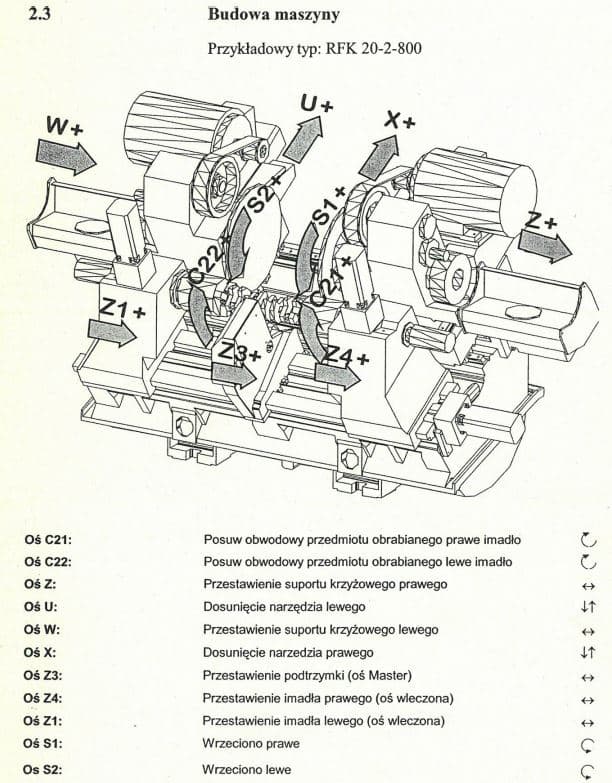

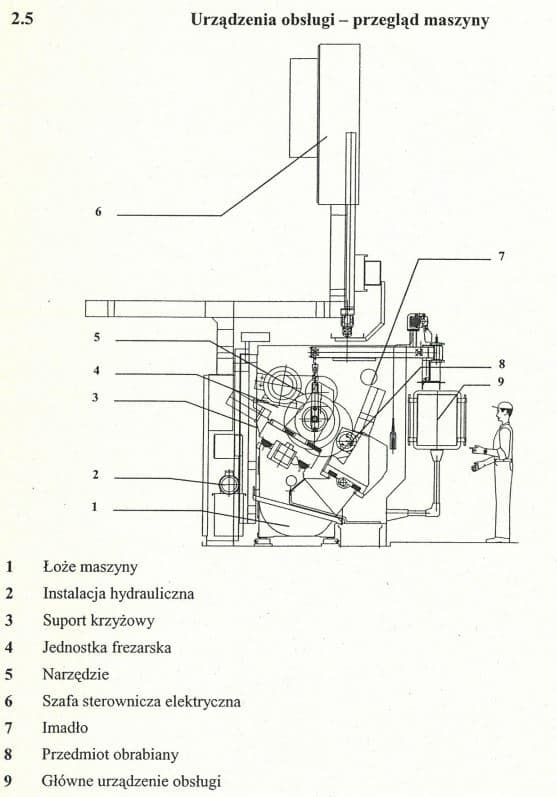

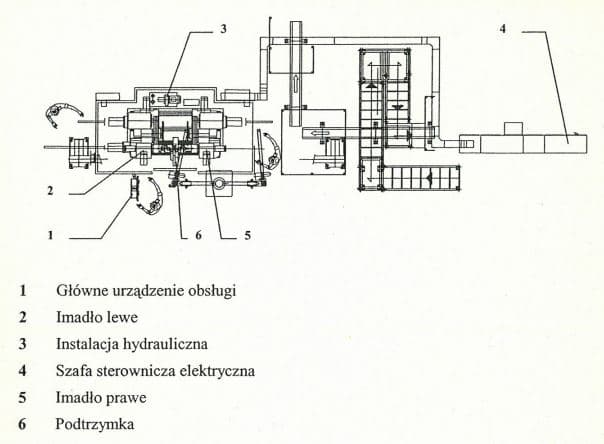

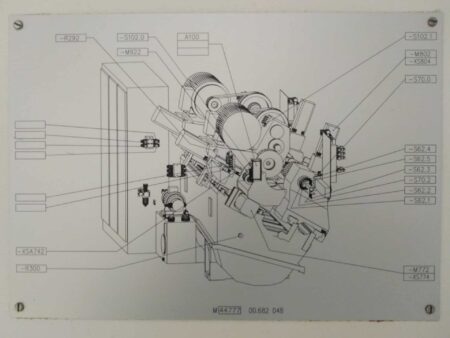

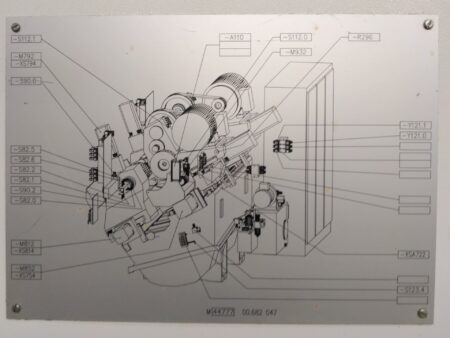

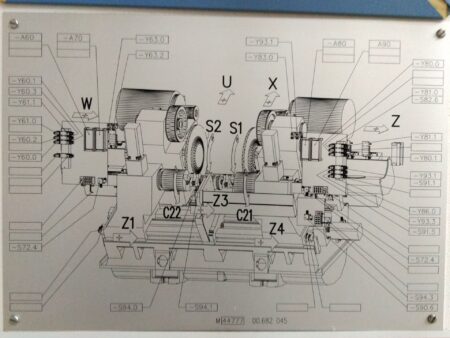

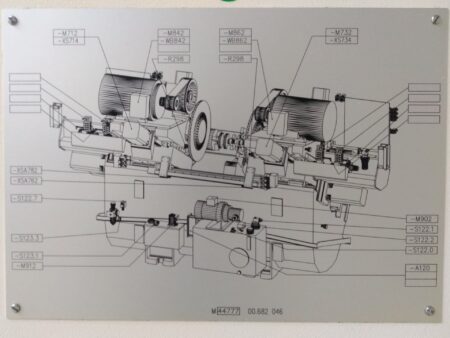

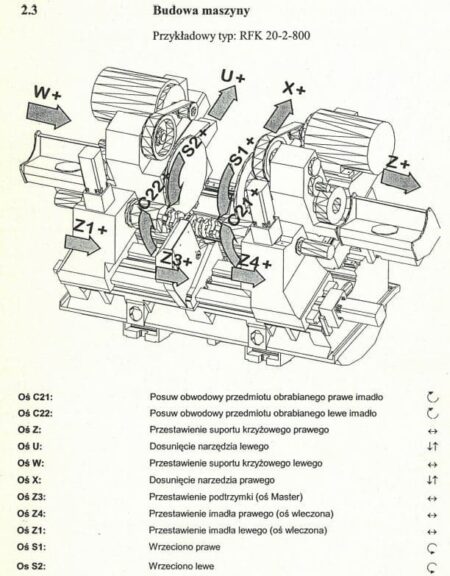

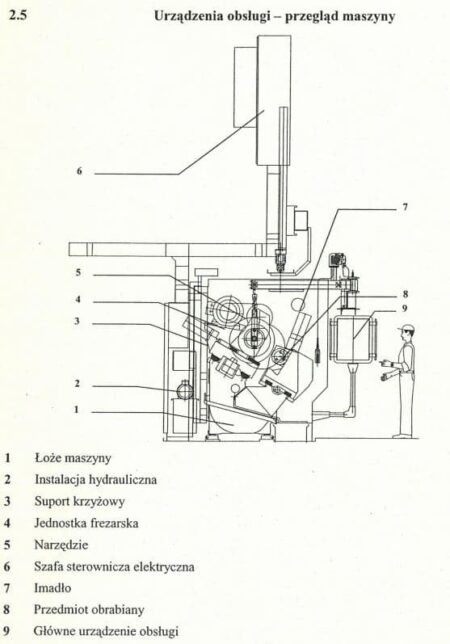

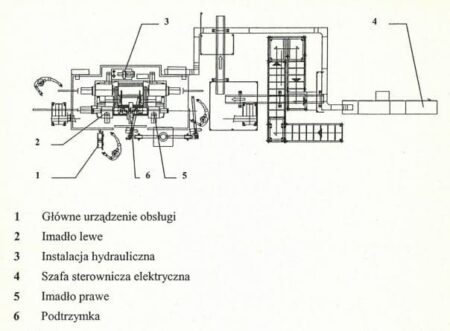

CNC crankshaft milling machine HELLER RFK 20-2-800 was built in 2001 by the German company Gebr. Heller Maschinenfabrik GmbH. The machine is designed for rough and finish milling of main bearings and/or lift bearings, including crankshaft sidewalls. The milling machine works in five axes with the feeds of 625 mm (W axis), 180 mm (U axis), 180 mm (X axis), 660 mm (Z axis) and 360° (C axis). The machine is controlled by the SIEMENS Sinumerik 840D CNC controller, processes a detail with a length of 800 mm and a diameter of 700 mm. The milling machine is characterized by a short workpiece replacement time, thanks to the freely accessible working space and a conveniently located clamping chuck. The total weight of the RFK 20-2-800 machine is 17 tons. We offer additional paid cutters for the machine for sale:

– IN11113502: 14265 EUR / 1 pcs.

– IIN11113500: 14330 EUR / 1 pcs.

Specification of the CNC crankshaft milling machine HELLER RFK 20-2-800

– CNC control: SIEMENS Sinumerik 840D

– detail length: 800 mm

– detail diameter: 700 mm

– milling rotational speed: 150-300 m/min

– feeds in the W / U / X / Z axes: 625/180/180/660 mm

– C axis of rotation: 360°

– diameter of the mounting clamp: 180 mm

– journal diameter: 35-80 mm

– sleigh diameter: 450 mm

– machine weight: 17 t

The advantages of the HELLER RFK 20-2-800 CNC milling machine

1. Economical service life through the use of re-usable multi-position cutting inserts and a dynamically rigid milling unit,

2. Short workpiece changeover times thanks to freely accessible working space, favourably positioned clamping chuck and easy automation capability,

3. Minimised set-up times thanks to easily presettable milling tools and quick tool changes

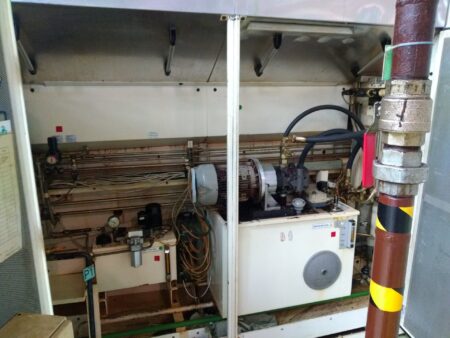

4. Long service life and excellent availability thanks to robust and easy-to-maintain design.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe