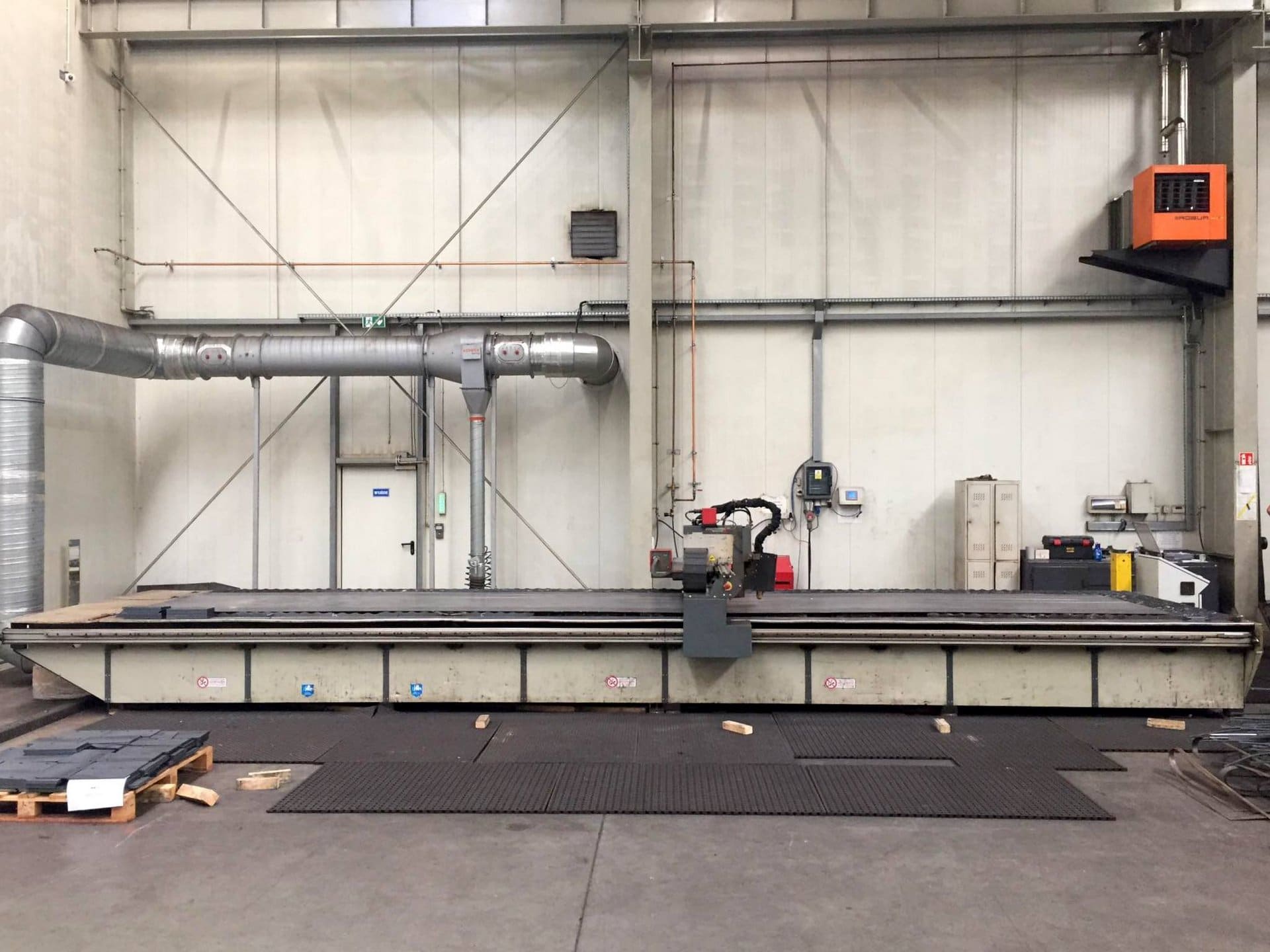

The CNC STIGAL DYNAMIC SPEED HQ plasma burner was built in 2016 by the Polish company Stigal. The plasma cutter provides high HQC (HD) cutting quality, and is also one of the fastest machines of this type – it performs machining in a much shorter time than other machines of this type. Voltage cutting torch with a positioning accuracy of + -0.05 mm moves at a speed of 90 m / min. The machine has a work table with dimensions (L x W) 2000 x 8000 mm, and its permissible load is 400 kg / m2. The burner is equipped with CNC G-CODE control and a PROF 166 HQC plasma aggregate with a maximum cutting current of 120 A. The device was regularly serviced and its consumables were replaced only on original elements.

Technical data of the CNC STIGAL DYNAMIC SPEED HQ plasma cutter

– dimensions of the working table (length x width): 2000 x 8000 mm

– cutting length: 8000 mm

– cutting width: 2000 mm

– permissible table load: 400 kg / m2

– maximum travel speed: 90 m / min

– burner positioning accuracy: + -0.05 mm

– speed of movement up / down the torch: 330 mm / s

– type of burner height adjustment: voltage

– suction connector: fi 315 mm

– maximum air humidity: 90%

– operating temperature range: from +5 to +40 degrees C

– power supply: 230 V; 50 Hz

– power consumption: 4000 W

– weight of the machine DYNAMIC SPEED HQ: 3000 kg

Accessories for the DYNAMIC SPEED HQ cutter

– CNC control: G-CODE

– plasma aggregate: PROF 166 HQC

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe