The CNC vertical milling center DECKEL MAHO DMU 50 EVOLUTION was built in 2000 by the renowned German company DMG Mori Seiki AG. The milling center works in five axes with maximum X / Y / Z axis travels of 500, 420 and 380 mm and maximum C / B axis travels of 180 and 360 degrees, respectively. The spindle rotates at a maximum speed of 18,000 revolutions per minute, and its power is 15 kW. The work table is 500 mm long and 380 mm wide. The milling machine is equipped with: CNC Heidenhain iTNC 430 numerical control, chip conveyor and a magazine for 32 tools. The total weight of the machine is 6 tons.

Technical data of the CNC vertical milling center DECKEL MAHO DMU 50 eVolution

– number of axis: 5

– dimensions of the working table (length x width): 500 x 380 mm

– maximum spindle speed: 18,000 rpm

– spindle power: 15 kW

– X / Y / Z axis travel: 500/420/380 mm

– C / B axis travel: 180/360 degrees

– maximum feed speed: 20 m/min

– total power: 40 kVa

– dimensions of the machine (L x W x H): 2800 x 2300 x 2600 mm

– working hours of the spindle: 14000 h

– machine switch-on hours: 68522 h

– machine working hours: 30801 h

– total weight: 6000 kg

Equipment of CNC milling machine DECKEL MAHO DMU 50 eVolution

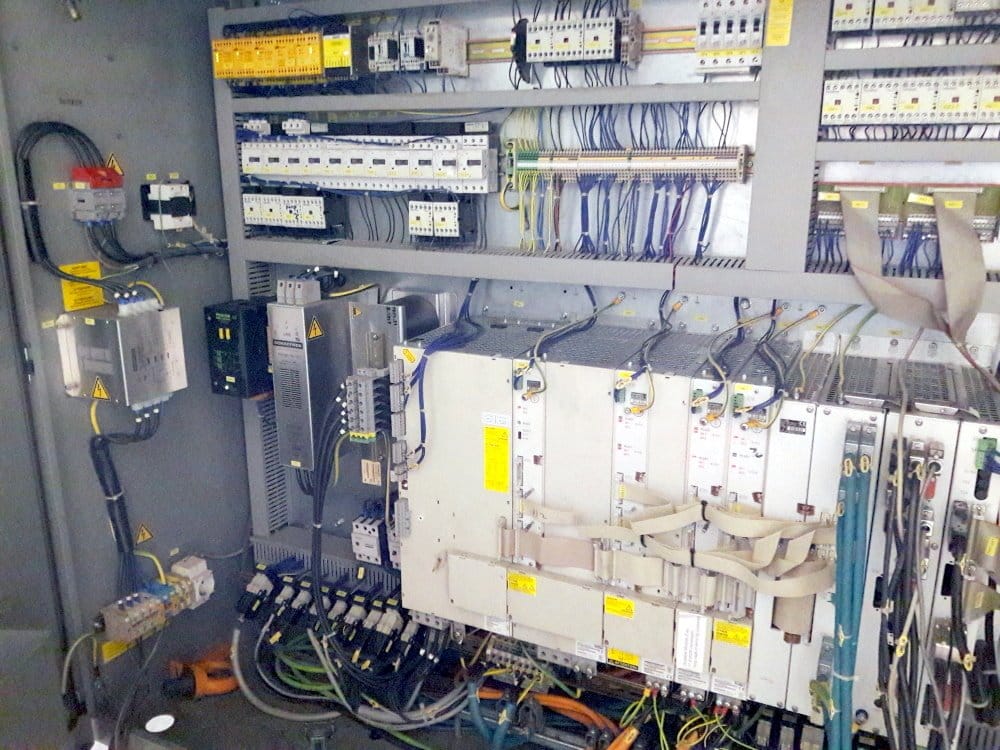

– CNC control: Heidenhain iTNC 430

– tool magazine capacity: 32 pcs.

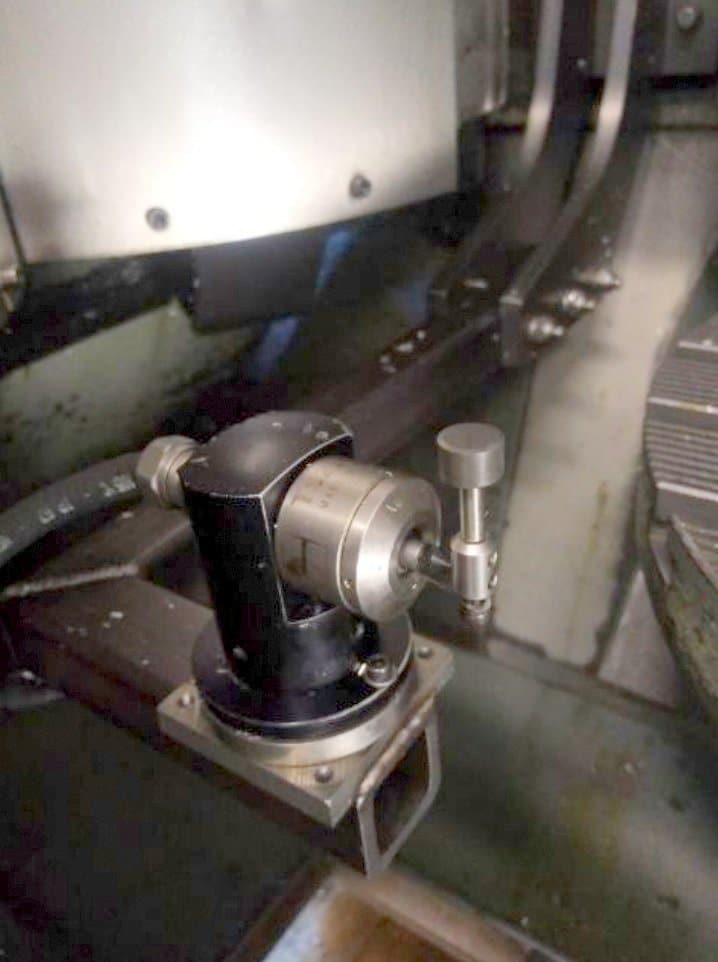

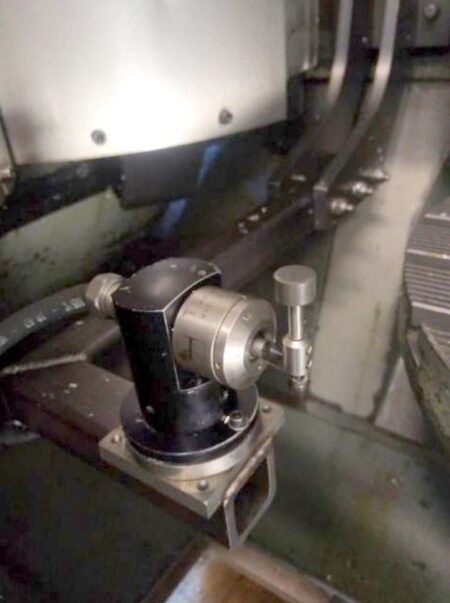

– tool probe

– spindle head: SK 40

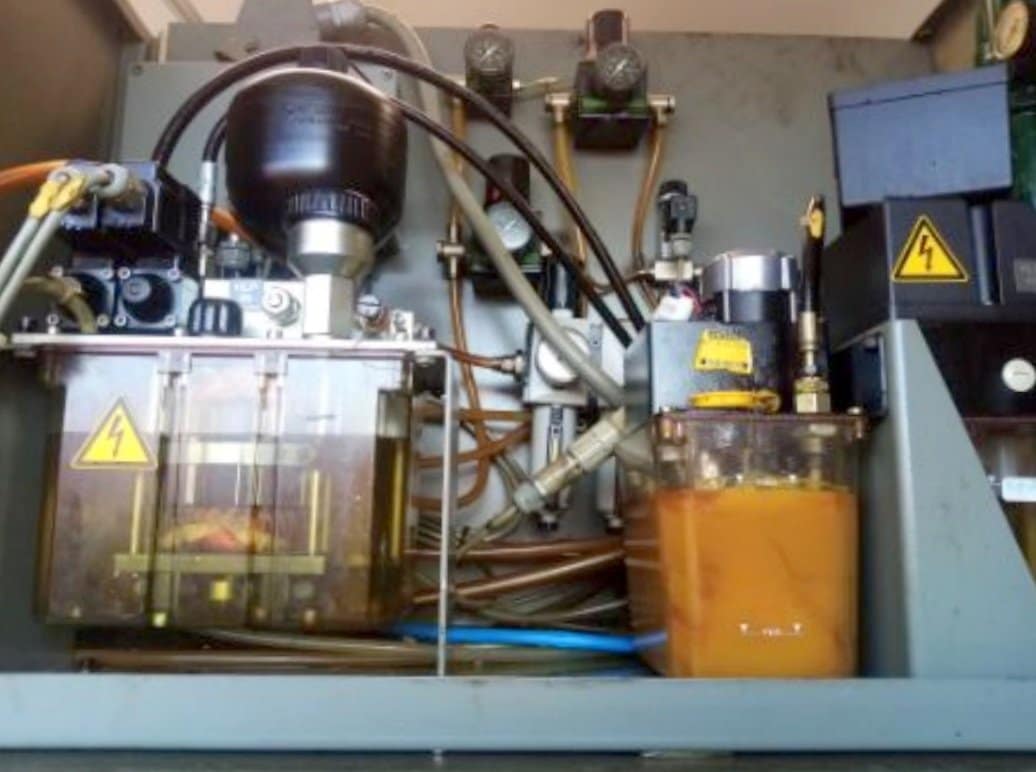

– cooling through the spindle

– chip conveyor

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe