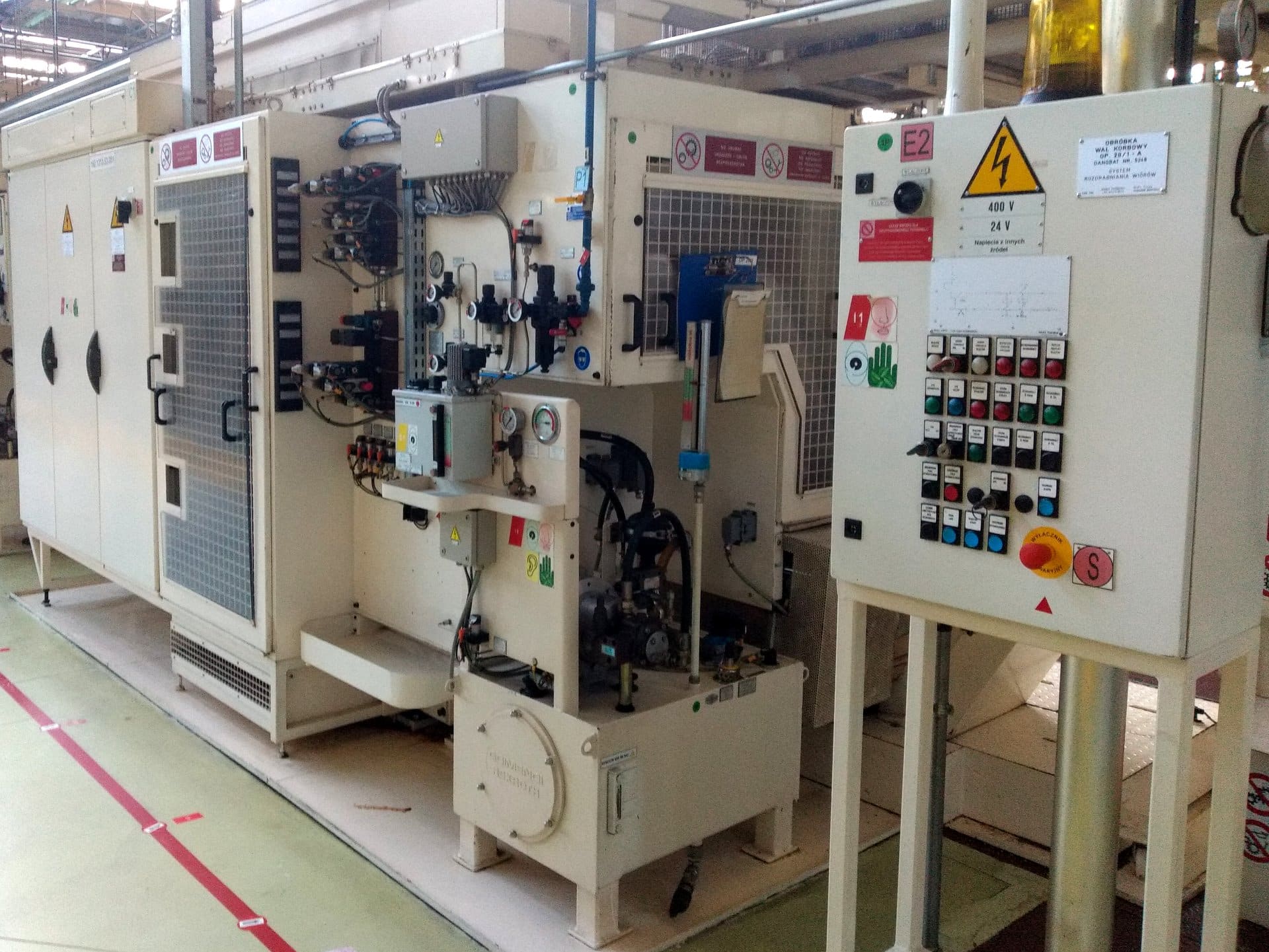

The DANOBAT NA 750 CNC lathe was manufactured in 2001 by the Spanish company Danobat S. Coop. The machine with a power of 45 kW, processes a workpiece with a maximum turning diameter over the bed of 700 mm. The machine is equipped with: DUPLOMATIC tool head with a capacity of 12 tools, a tool measurement probe and a SIEMENS Sinumerik CNC control. The lathe works in two axes X and Z with maximum feeds of 255 mm (X axis) and 520 mm (Z axis). On the other hand, rapid feeds in the X and Z axes are 20 m/min. The total weight of the NA750 machine is 11,500 kg.

Technical data of the DANOBAT NA 750 CNC lathe

– CNC control: SIEMENS Sinumerik

– turning diameter over the bed: 700 mm

– maximum feeds in the X / Z axis: 255/520 mm

– rapid feeds in the X and Z axis: 20 m/min

– sleeve diameter: 120 mm

– sleeve movement range: 100 mm

– spindle tip: ASA-8

– maximum distance between the spindle tip and the left tool head: 935 mm

– internal diameter of spindle bearings: 150 mm

– tool head: DUPLOMATIC

– tool head capacity: 12 tools

– range of movement of the tool head in the X axis: 245 mm

– tool measurement probe

– power: 45 kW

– weight of the CNC lathe NA-750: 11500 kg

Tailstock of DANOBAT NA 750

The tailstock is the basic element of the lathe that allows you to take full advantage of its capabilities. A tailstock clamps the right end of the machined part, thus increasing the machining accuracy. In addition, it absorbs external forces acting on the blank. The tailstock sleeve is a support for the tailstock sleeve mounted on precision bearings. All tailstock bearings are lubricated with Kluber ISOFLEX SUPER LDS-18 grease and are maintenance-free. The tip of the tailstock with a Morse MK5 taper is made of steel with increased hardness, which ensures long-term operation. The tailstock can be controlled manually from the control panel. Tailstock pressure must be set before tailstock operation can begin. The tailstock is manually attached to the guides with bolts and blocks that fix its position. The working pressure of the tailstock can be read from the pressure gauge located on the hydraulic panel.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe