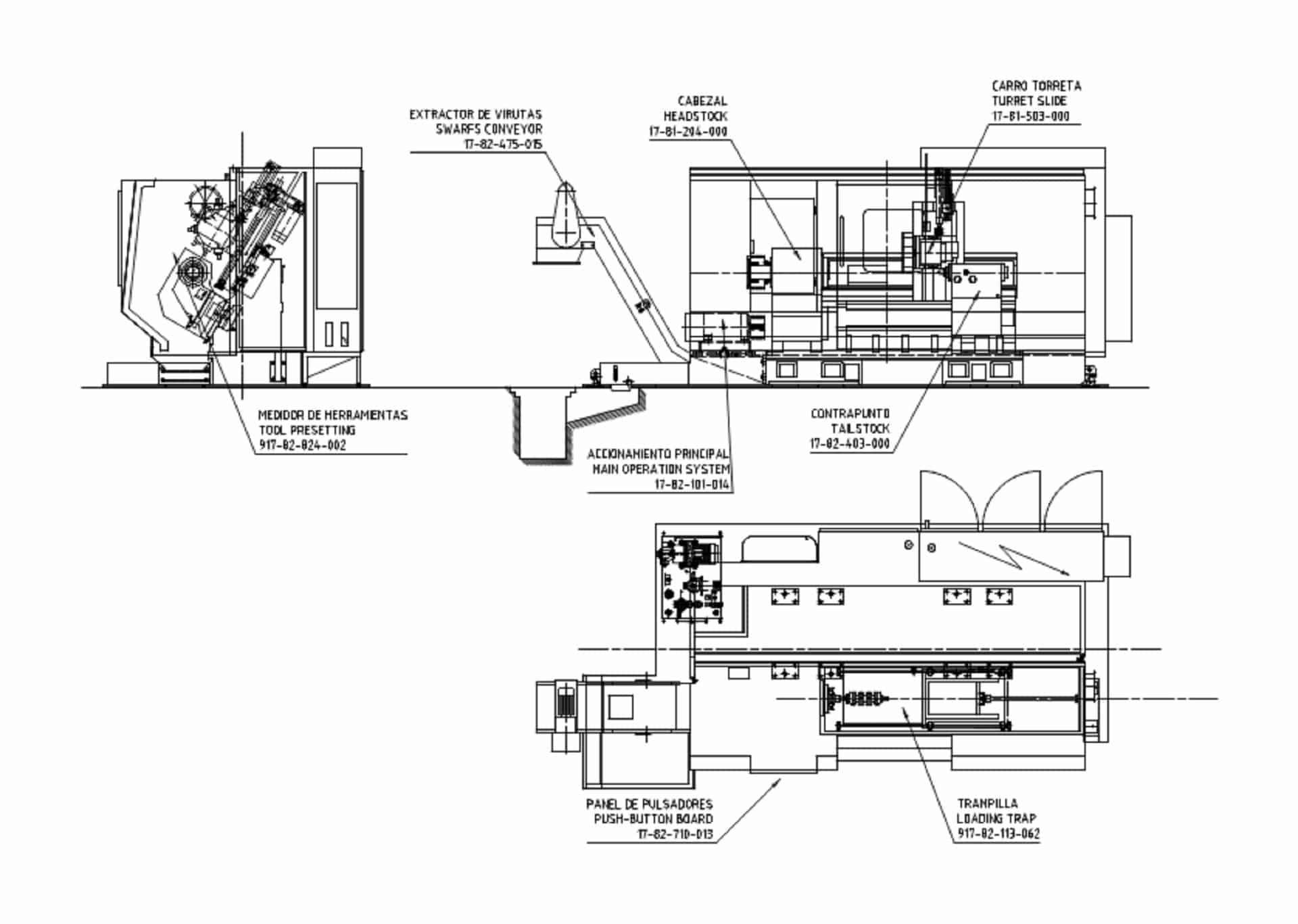

The DANOBAT NA 750 CNC lathe was manufactured in 2001 by Danobat S. Coop. in Spain. The machine, equipped with a SIEMENS Sinumerik CNC control and operates in two axes, X and Z, with maximum feeds of 255 and 520 mm respectively. Fast feeds in axes are 20 m/min.

The headstock of the lathe consists of a main spindle placed on bearings and a pulley receiving the rotational movement. The main spindle is driven by the main motor through a belt. The tailstock tip with an Morse MK5 cone is made of steel with increased hardness, which ensures long-lasting operation. The headstock roller bearings and tailstock bearings are lubricated with KLUBER ISOFLEX SUPER LDS-18 grease.

The workpiece may have a maximum turning diameter of 700 mm above the bed. The machine is also equipped with a tool measuring probe, an Morse MK5 cone and a DUPLOMATIC tool head, accommodating 12 tools. The CNC lathe NA 750 weighs 11.5 t.

Specifications of DANOBAT CNC lathe NA 750

- CNC control: SIEMENS Sinumerik

- turning diameter above the bed: 700 mm

- maximum feeds in X/Z axis: 255/520 mm

- rapid feeds in the X and Z axis: 20 m/min

- sleeve diameter: 120 mm

- bush movement range: 100 mm

- spindle end: ASA-8

- cone: Morse MK5

- optical measuring scale: HEINDENHAIN LS186 ML340

- maximum distance between spindle nose and left tool head: 935 mm

- internal diameter of spindle bearings: 150 mm

- tool head: DUPLOMATIC

- tool head capacity: 12 tools

- tool head travel range in X axis: 245 mm

- tool measuring probe

- power: 45 kW

- lathe weight: 11500 kg

Tool head of a DANOBAT automatic lathe

The head of the NA750 lathe has been constructed so as to provide access for tools to the entire workspace. In addition, it allows for easy and quick tool changes, which facilitates the operator’s work. The tool head provides maximum setting repeatability precision and excellent rigidity. It uses the Couvic-Coupling positioning system, which selects the shortest tool change path. The heads can be equipped with an 8 or 12 tool disk, and the disk can be provided with different diameters of tool holes.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe