DECKEL MAHO DMC 50 V CNC machining center was built in Germany in 1995. The machine distinguished by its robust, stable construction is used in precision face and hole machining using rotary tools. The machine is ideal for use in any production facility thanks to its reliable components, such as the high-performance FRANZ KESSLER DMS100.AL.4.FOM spindle and the 20-position tool magazine with automatic tool changing, which guarantee perfect milling precision and accuracy. The DECKEL MAHO CNC vertical machining center weighs 7000 kg.

Technical specifications of the DECKEL MAHO DMC 50 V CNC milling machine

- work table dimensions (L x W): 700 x 400 mm

- feed rates in the X/Y/Z axis: 500/420/500 mm

- speed of feeds in the X/Y/Z axis: 1-2000 mm/min

- feed motor power in the X/Y/Z axis: 3.5 kW

- maximum workpiece weight: 800 kg

- maximum spindle rotational speed: 15000 rpm

- maximum distance between spindle end and work table: 650 mm

- minimum distance between spindle end and work table: 150 mm

- spindle power: 15 kW

- maximum tool height: 90 mm

- tool length from spindle end: 300 mm

- maximum tool weight: 12 kg

- pneumatic system pressure: 6 bar

- power: 50 kW

- power supply: 3x 400 V; 50 Hz

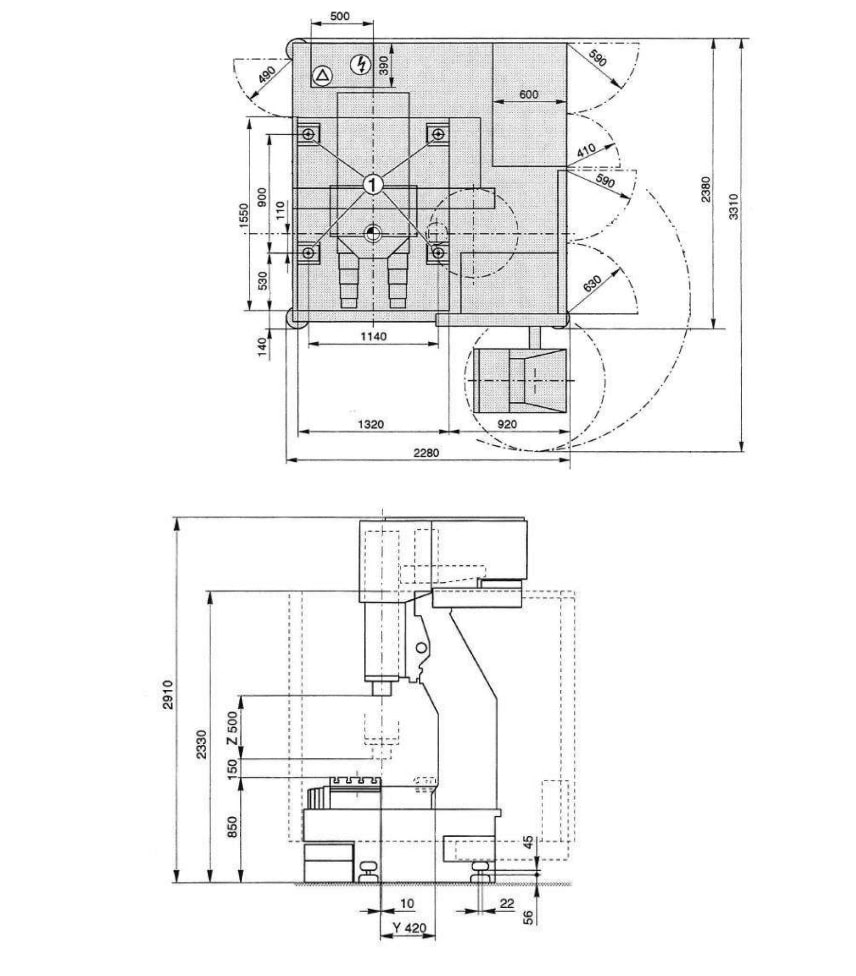

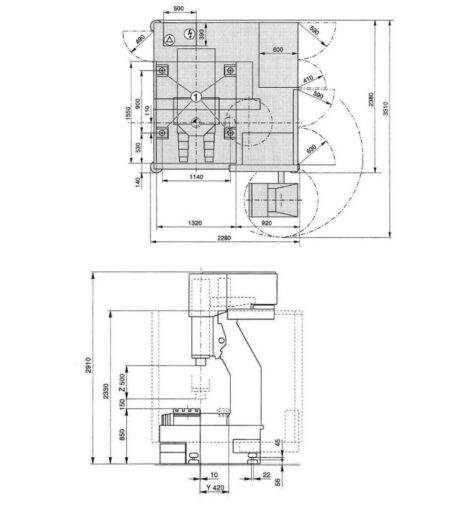

- dimensions (L x W x H): 2280 x 3310 x 2910 mm

- weight of machine: 7000 kg

Equipment of the DMC 50V milling center

- CNC control: DIALOG 112

- 20-position tool magazine

- spindle: FRANZ KESSLER DMS100.AL.4.FOM

- spindle taper: SK40

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe