DECKEL MAHO DMU 60 T CNC vertical machining centre was built in Germany in 1999. The machine performs precision machining of workpieces weighing up to 350 kg, in three axes with feeds of 600 mm (X axis), 525 mm (Y axis) and 500 mm (Z axis). Workpieces are placed on a work table with the dimensions (L x W): 900 x 500 mm and they may also be machined horizontally, thanks to the mounted detachable milling head

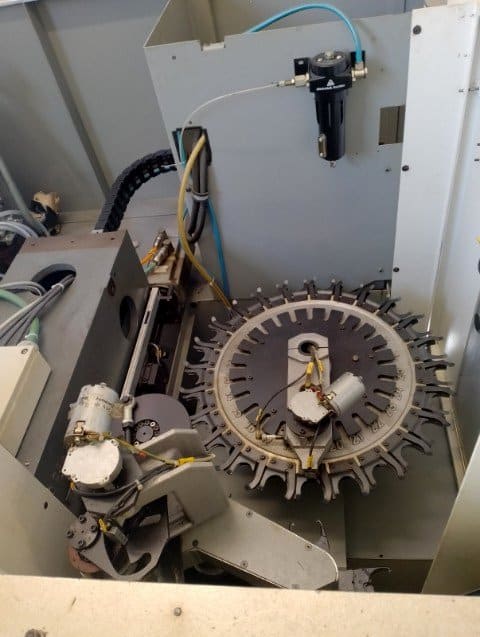

The high-performance spindle of the milling centre rotating at a speed of 12000 rpm, together with the advanced HEIDENHAIN Mill+ numerical control, guarantee excellent precision, quality and a significant reduction in machining time. The milling centre’s tool magazine has a capacity of 25 tools and provides tool changes in a very short time. The CNC milling machine is also equipped with a post-processor with CAD/CAM software and a desktop computer. The total weight of the machine is 4200 kg.

Technical data of the DECKEL MAHO DMU 60 T milling centre

- size of work table (L x W): 900 x 500 mm

- maximum workpiece weight: 350 kg

- feed rates in the X/Y/Z axis: 600/525/500 mm

- rapid feed rates in the X,Y axis: 18 m/min

- rapid feed rate in the Z axis: 17 m/min

- maximum spindle speed: 12000 rpm

- tool magazine capacity: 25 pcs.

- vertical manual rotary milling head (X,Y,Z axis): 20 – 10000 mm/min

- number of t-slots: 8

- distance between t-slots: 63 mm

- overall dimensions (L x W x H): 2950 x 2200 x 2550 mm

- total weight of the DMU 60T machine: 4200 kg

Equipment of the machining centre

- CNC control: HEIDENHAIN Mill+

- spindle taper: SK 40

- post-processor with CAD/CAM software

- pumping tub

- desktop computer

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe