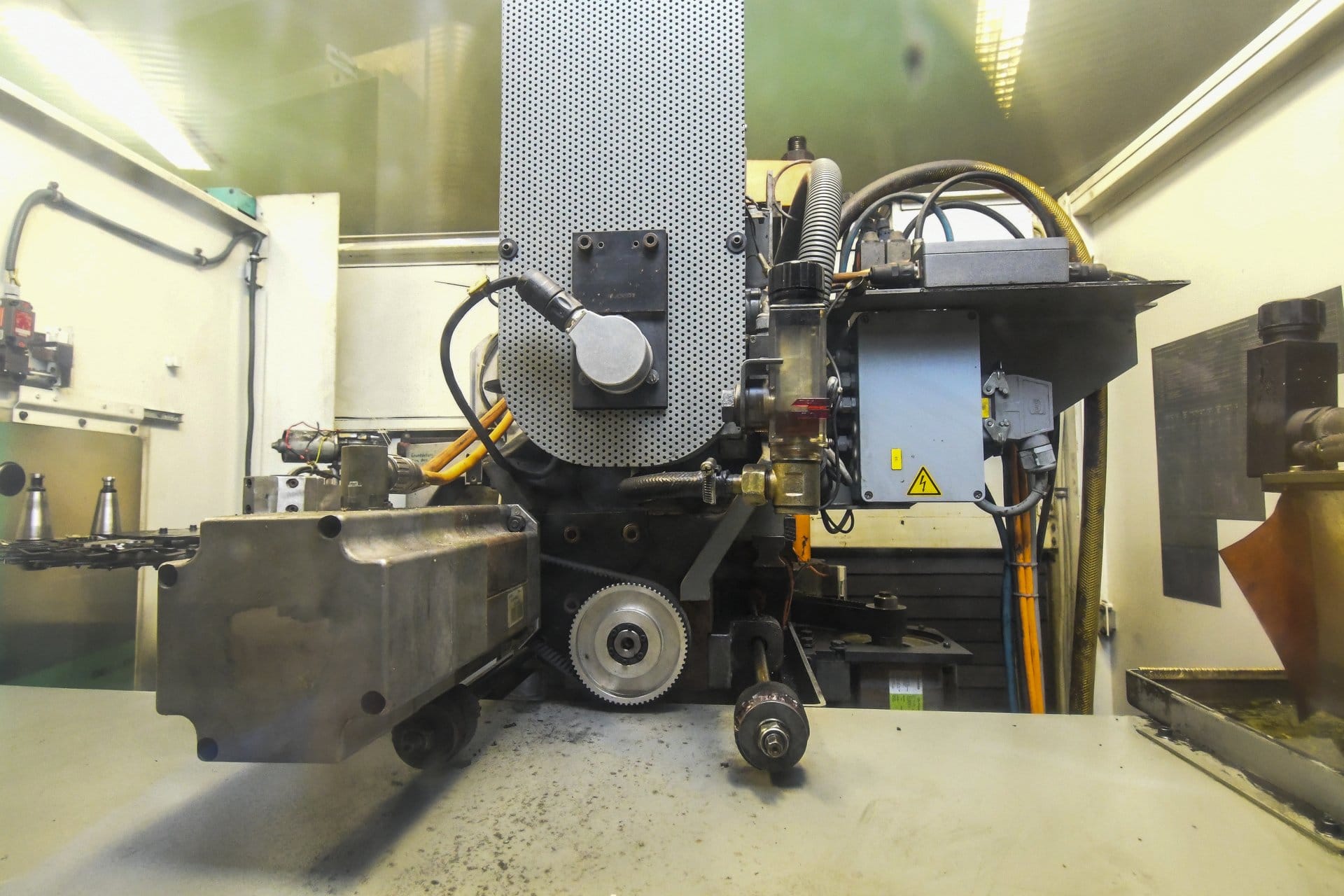

The DECKEL MAHO DMU 60 T vertical machining center was built by the German company DMG Mori Seiki AG in 1999. The machine works in three axes (X, Y, Z), and their maximum travels are, respectively: 600, 525 and 500 mm. The milling spindle rotates in the range from 20 to 6300 rpm. The tilting rotary table with dimensions (L x W) 900 x 500 mm allows for processing of details with a maximum weight of 350 kg. The machine is equipped with rulers, a tool feeder and a HEIDENHAIN 426 CNC control. The milling machine also allows horizontal milling, thanks to a detachable head.

Characteristic data of the DECKEL MAHO DMU 60 T milling machine

– CNC control: HEIDENHAIN 426

– dimensions of the tilting-rotary table (L x W): 900 x 500 mm

– maximum table load: 350 kg

– maximum feeds in the X / Y / Z axes: 600/525/500 mm

– rapid feeds in the X and Y axis: 18 m/min

– rapid feeds in the Z axis: 17 m/min

– spindle speed: 20 – 6300 rpm

– vertical, manual and rotary milling head (X, Y, Z axis): 20 – 10,000 mm/min

– number of T-slots: 8

– spacing of T-slots: 63 mm

– tool holder: SK 40

– spindle: SK 40 (6 pcs.)

– tool changer: 25 pcs.

– bathtub with a pump

– machine dimensions (L x W x H): 295 x 220 x 255 cm

– total weight of machine: 4200 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe