DMG DMC 1035 V ECOLINE CNC machining centre, built in Germany in 2010, performs precision machining of workpieces weighing up to 1000 kg. Excellent rigidity and precision machining is ensured by the high quality cast iron C-type structure, equipped with a powerful spindle operating at a maximum speed of 8000 rpm. Milling of workpieces is performed on an easily accessible work table with dimensions (L x W) of 1200 x 560 mm, equipped with five T-slots.

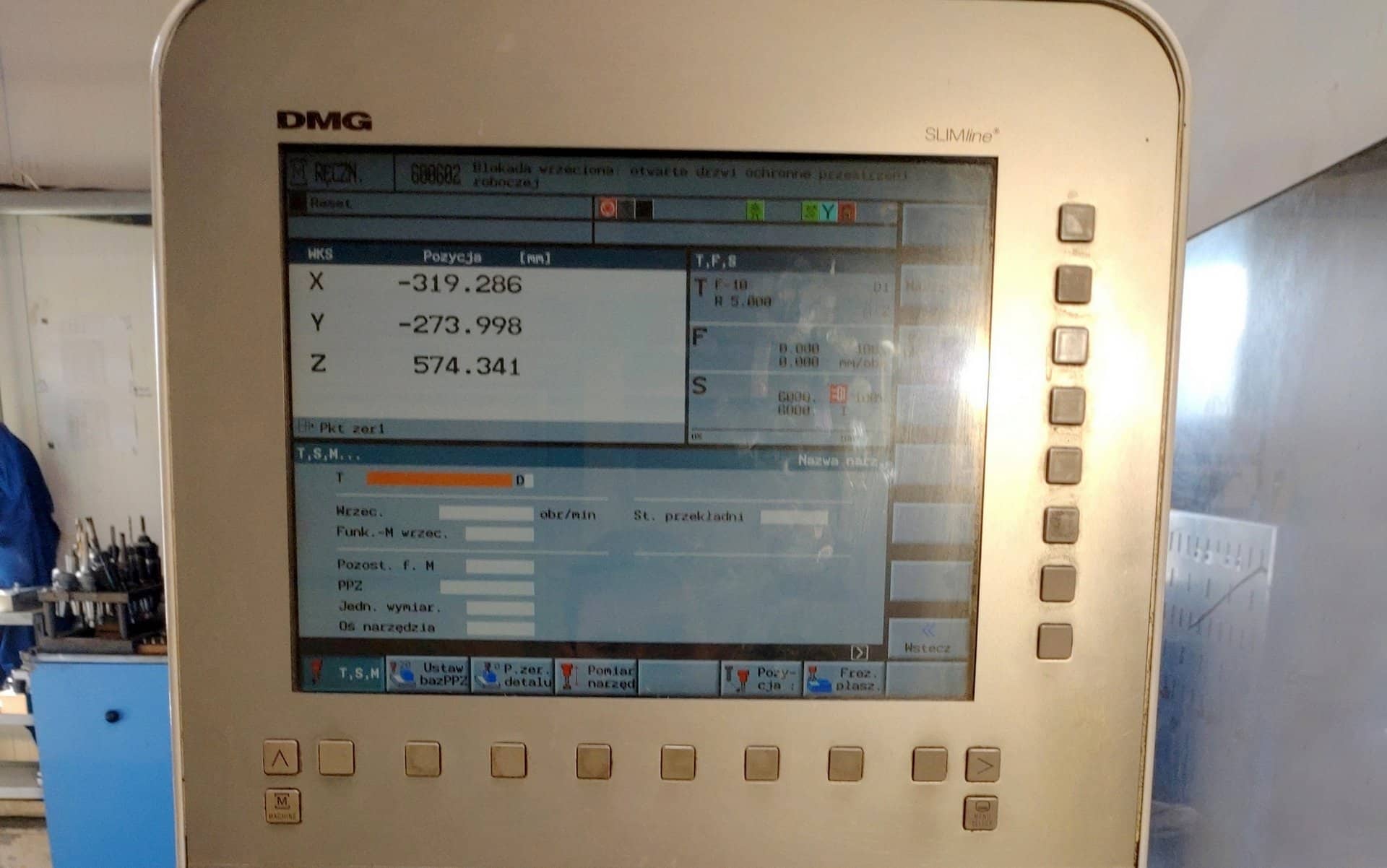

The DMG MORI DMC 1035 V ECOLINE CNC vertical machining centre is numerically controlled using a modern and functional SIEMENS SINUMERIK 810D CNC controller, allowing programming of the machining modes and full control of the machine operation. The milling centre also features three driven axes with feed rates of 1035 mm (X axis), 560 mm (Y axis) and 510 mm (Z axis), as well as a twenty position tool magazine with double gripper. The total weight of the CNC milling machine is 4100 kg.

Technical data of the DMG DMC 1035 V ECOLINE CNC milling centre

- CNC control: SIEMENS SINUMERIK 810D

- control panel: DMG MORI SLIMline

- work table surface (L x W): 1200 x 560 mm

- maximum workpiece weight: 1000 kg

- number of driven axes: 3

- feed rates in the X/Y/Z axis: 1035/560/510 mm

- speed of feed rates in the X/Y/Z axis: 20 m/min

- rapid traverse speed in the X/Y/Z axis: 25 m/min

- maximum spindle speed: 8000 rpm

- tool magazine capacity: 20 pcs.

- tool holder: SK40

- maximum tool weight: 6 kg

- maximum tool length: 300 mm

- tool change time: 1,6 s

- number of T-slots: 5

- main motor power: 13 kW

- overall dimensions (L x W x H): 4400 x 5550 x 2800 mm

- total weight of the DMC 1035 V ECOLINE machine: 4100 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe