DMG DMC 635 V ECO CNC machining centre was manufactured in Germany in 2011. The machine is used for precise machining of metal workpieces weighing up to 600 kg, in three axes with feeds of 635 mm (X axis), 510 mm (Z axis) and 460 mm (Z axis). The DMG Ecoline milling machine’s high-quality cast-iron frame, together with the axes equipped in roller guides, ensure great sturdiness and stability during the machining process.

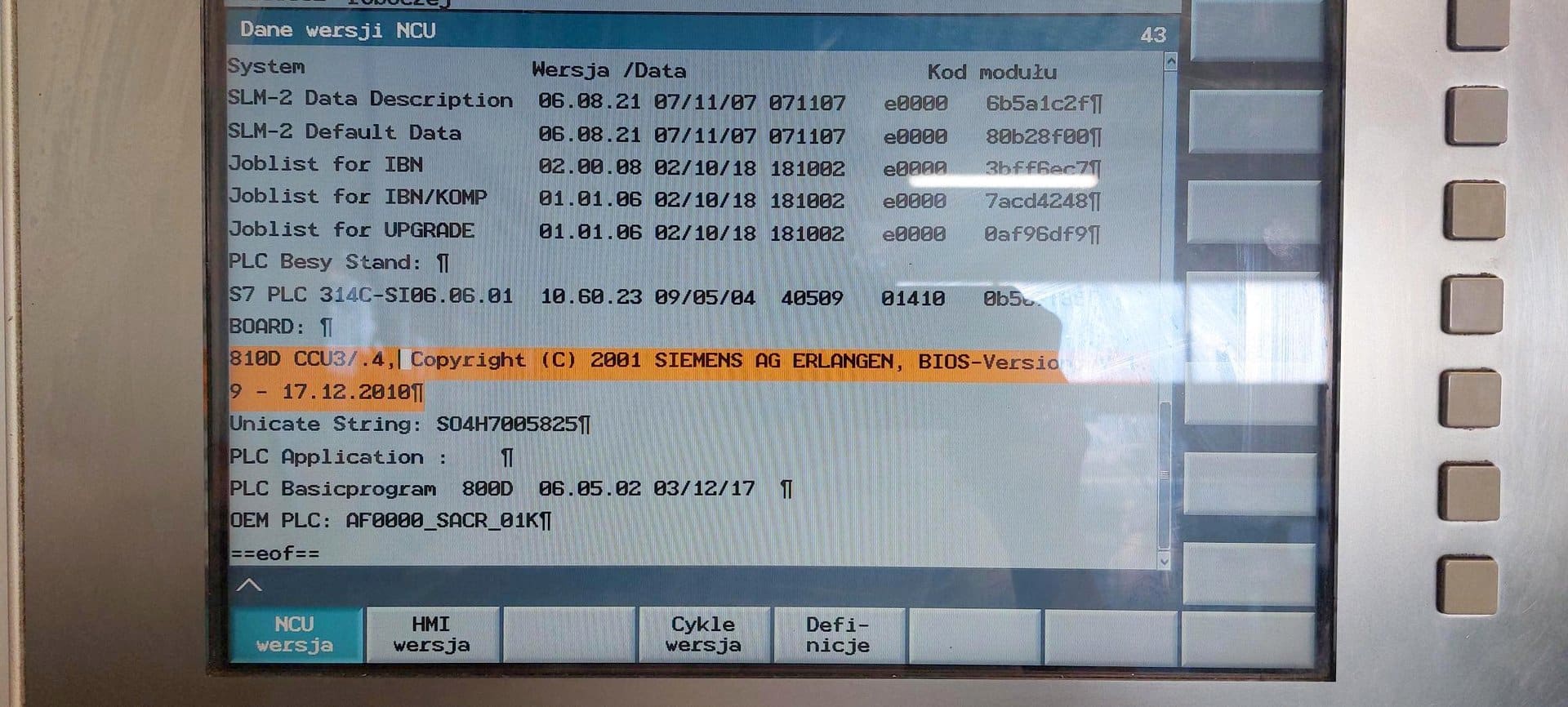

The high-speed spindle of the milling centre rotating at a speed of 10000 rpm together with the 20-position tool head with quick tool change, significantly reduce the time of milling procces. The operator’s high level of comfort is ensured by the arm-mounted control panel with installed SIEMENS SINUMERIK 810D numerical control, as well as the machine’s easily accessible working area. The total weight of the CNC milling machine is 3900 kg.

Technical data of the DMG DMC 635 V ECO CNC milling centre

- CNC control: SIEMENS SINUMERIK 810D

- control panel: DMG MORI SLIMline

- number of controlled axes: 3

- feed rates in the X/Y/Z axis: 635/510/460 mm

- rapid traverse in the X,Y,Z axis: 25 m/min

- working table size (L x W): 790 x 560 mm

- maximum workpiece weight: 600 kg

- maximum spindle speed: 10000 rpm

- spindle taper: SK 40

- tool magazine capacity: 20 pcs.

- maximum tool diameter: 80 mm

- maximum tool length: 300 mm

- maximum tool weight: 6 kg

- tool change time: 1,6 s

- minimum distance of spindle from table: 120 mm

- maximum distance of spindle from table: 580 mm

- number of t-slots: 5

- distance between t-slots: 100 mm

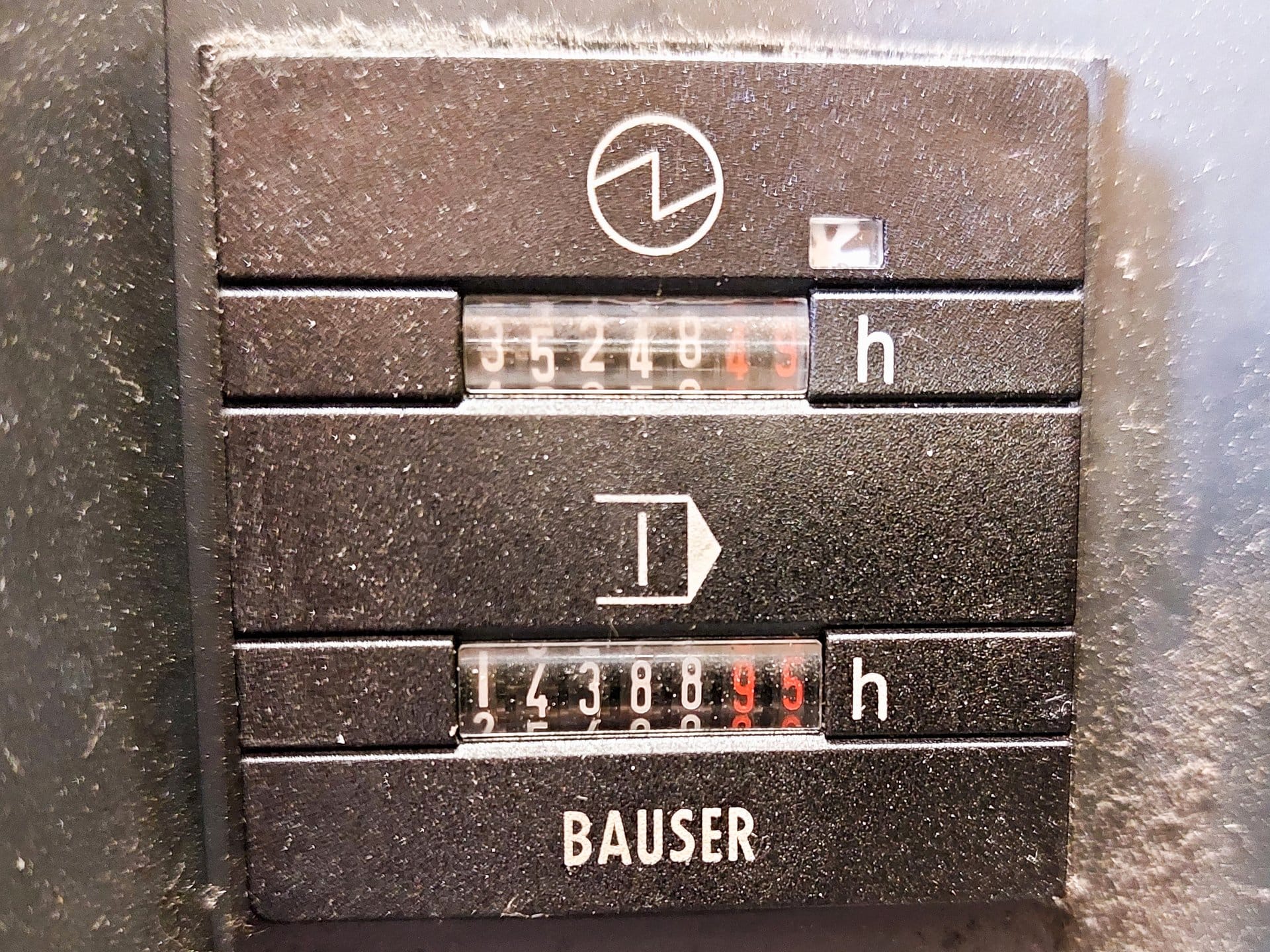

- working hours: 14388 h

- total power requirement: 17 kVA

- overall dimensions (L x W x H): 2050 x 2530 x 2650 mm

- total weight of DMC 635 V Ecoline machine: 3900 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe