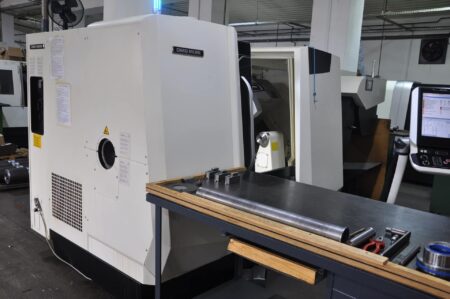

DMG MORI CLX 350 CNC turning center manufactured in 2017 is used for precision machining of workpieces with a maximum diameter of 610 mm. In order to meet even the most intensive production challenges, the machine uses high-quality components and modern solutions. Inside the large working area, there is a specially designed inclined bed that dampens any vibrations and oscillations generated during machining. This solution results in, among others, a better quality of the machined surface or an increased service life of the cutting tools. To this date, the DMG MORI CNC lathe has only worked for 4611 hours. The total weight of the machine is approximately 4700 kg.

Technical data of the DMG MORI CLX 350 lathe

- maximum turning diameter: 320 mm

- turning diameter (over the bed): 610 mm

- turning diameter (over cross sledge): 400 mm

- turning length: 530 mm

- feed in the X/Z axis: 242.5/580 mm

- rapid traverse in the X/Z axis: 30/36 m/min

- maximum spindle rotational speed: 5000 rpm

- spindle end: A2-6

- front spindle bearing diameter: 120 mm

- spindle drive power (40/100% DC): 16.5/11 kW

- maximum spindle torque (40/100% DC): 168/112 Nm

- number of driven tools: 12 pcs.

- bar diameter: 51 mm

- tailstock travel: 550 mm

- maximum tailstock power: 4 kN

- X/Z-axis positioning accuracy: 5/87 µm

- C-axis positioning accuracy: 20 arcsec

- operating hours: 4611 h

- weight of machine including chip conveyor: approx. 4700 kg

Equipment of the CLX 350 turning center

- CNC control: SIEMENS SINUMERIK 840D Solution Line

- 19″ DMG MORI SLIMline colour touchscreen control panel with 3D module

- 12-position turret with VDI 30 toolholders

- integrated chip conveyor

- foot switch controller

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe