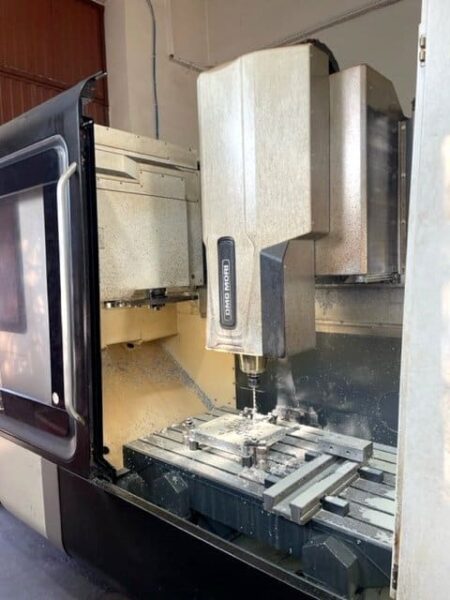

DMG MORI DMC 1150 V CNC machining centre built in Japan in 2017, is designed for machining workpieces having a maximum weight of 1500 kg. The machine has three numerically controlled axes with feeds of 1150 mm (X-axis), 700 mm (Y-axis) and 550 mm (Z-axis) respectively, and rapid feeds of 36 m/min. Vibrations generated during the milling process are completely eliminated, thanks to the use of a polymer concrete bed of high rigidity.

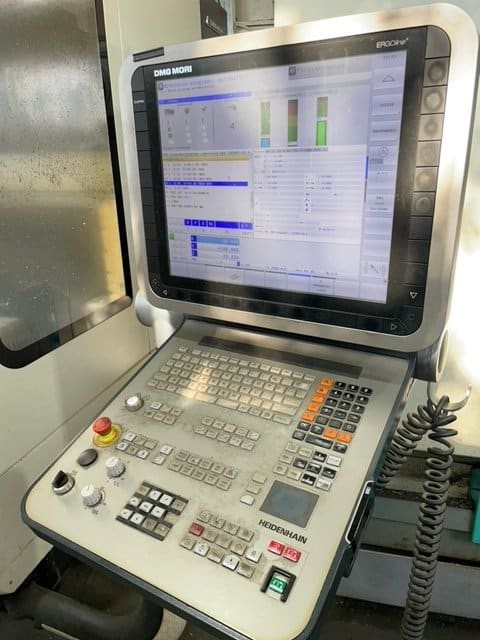

The spindle, rotating with a speed of 12000 rpm and equipped with innovative cooling system and SK 40 taper, guarantees excellent quality, precision and a significantly reduced duration of the milling process. The vertical machining centre is controlled by an intuitive DMG ERGOline control panel with installed HEIDENHAIN TNC 640 CNC controller providing full control of the machine operation. The extensive equipment of the milling centre consists of among others: a HEIDENHAIN TS 649 workpiece measuring probe with infrared transmission and a chip conveyor. The total weight of the milling centre is 8800 kg.

Technical data of the DMG MORI DMC 1150 V machining centre

- working table dimensions (L x W): 1400 x 750 mm

- feed rates in the X/Y/Z axis: 1150/700/550 mm

- rapid feed rates in the X,Y,Z axis: 36 m/min

- maximum workpiece weight: 1500 kg

- maximum workpiece height: 820 mm

- minimum spindle speed: 20 rpm

- maximum spindle speed: 12000 rpm

- maximum spindle power: 14.5 kW

- maximum spindle torque: 121 Nm

- tool magazine capacity: 20 pcs.

- maximum tool diameter: 80 mm

- maximum tool length: 300 mm

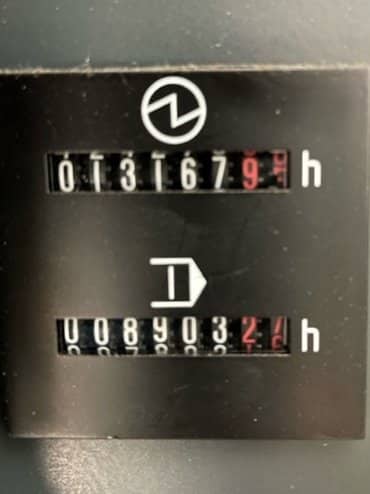

- operating hours: 8903 h

- overall dimensions (L x W x H): 4082 x 2659 x 2910 mm

- total weight of machine DMC 1150V: 8800 kg

Equipment of the CNC milling machine

- CNC controller: HEIDENHAIN TNC 640

- workpiece measuring probe: HEIDENHAIN TS 649

- spindle taper: SK 40

- control panel: DMG ERGOline 19″

- cooling through spindle

- chip conveyor

- technical documentation of the machine in Polish and English

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe