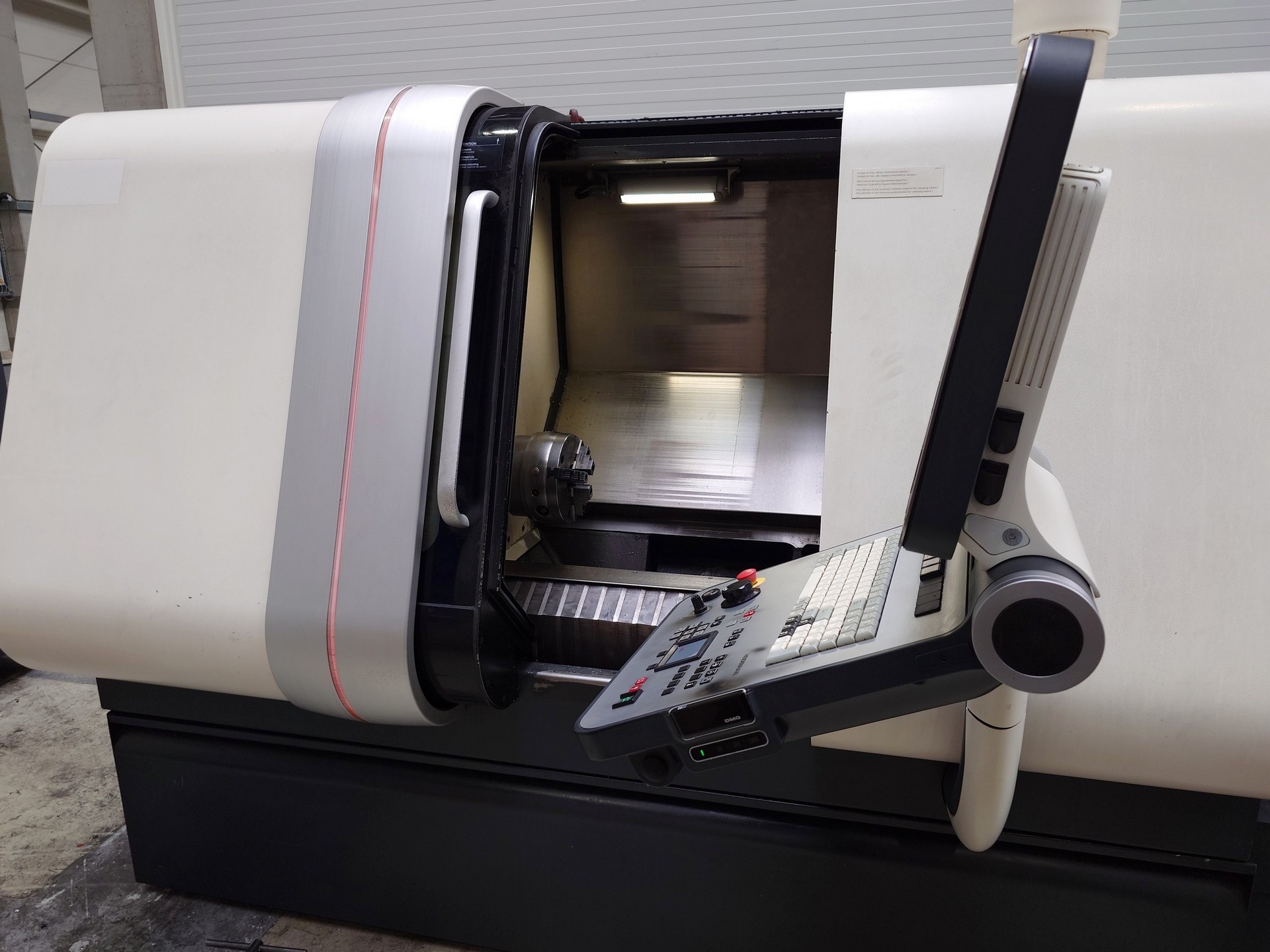

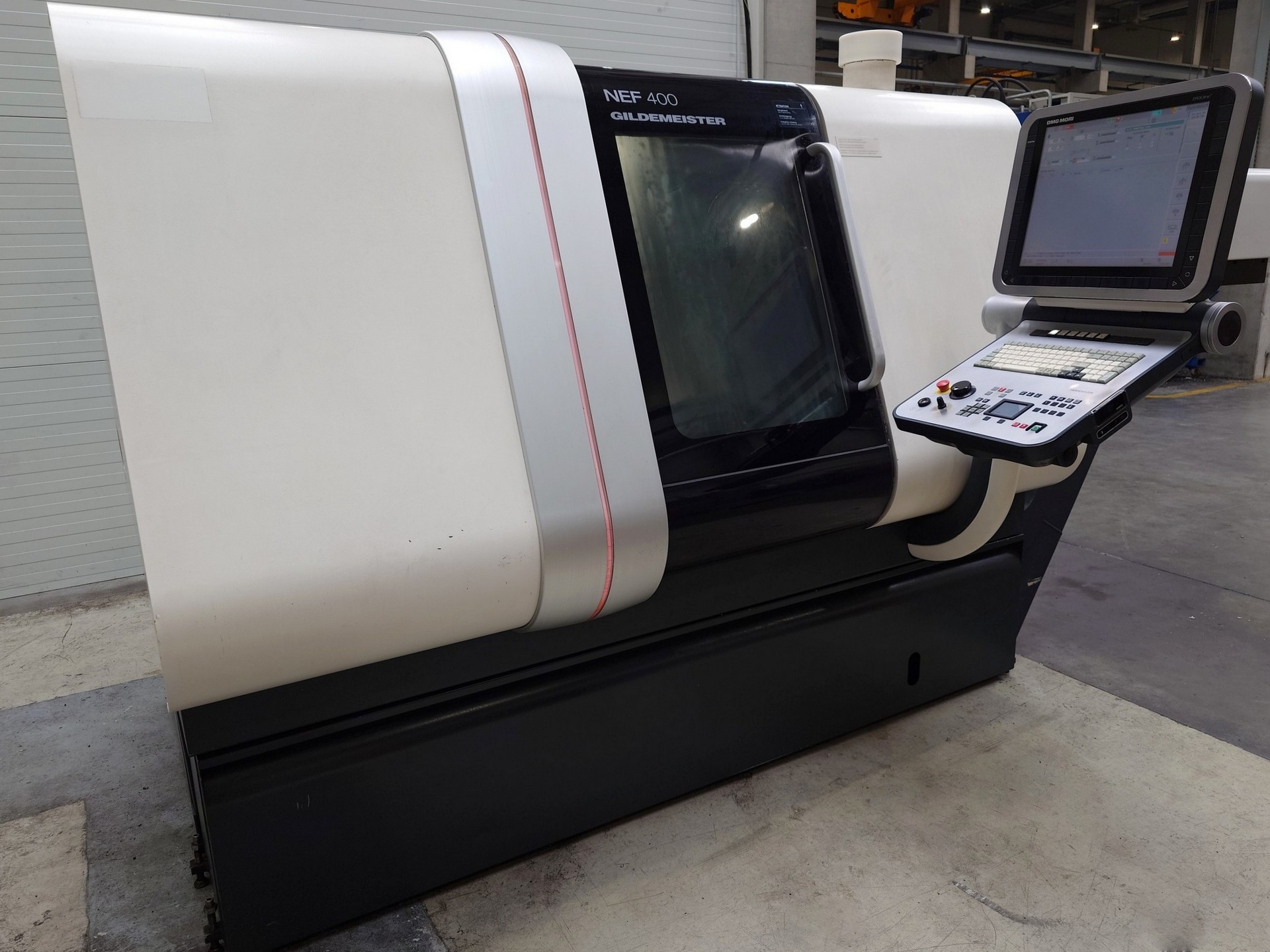

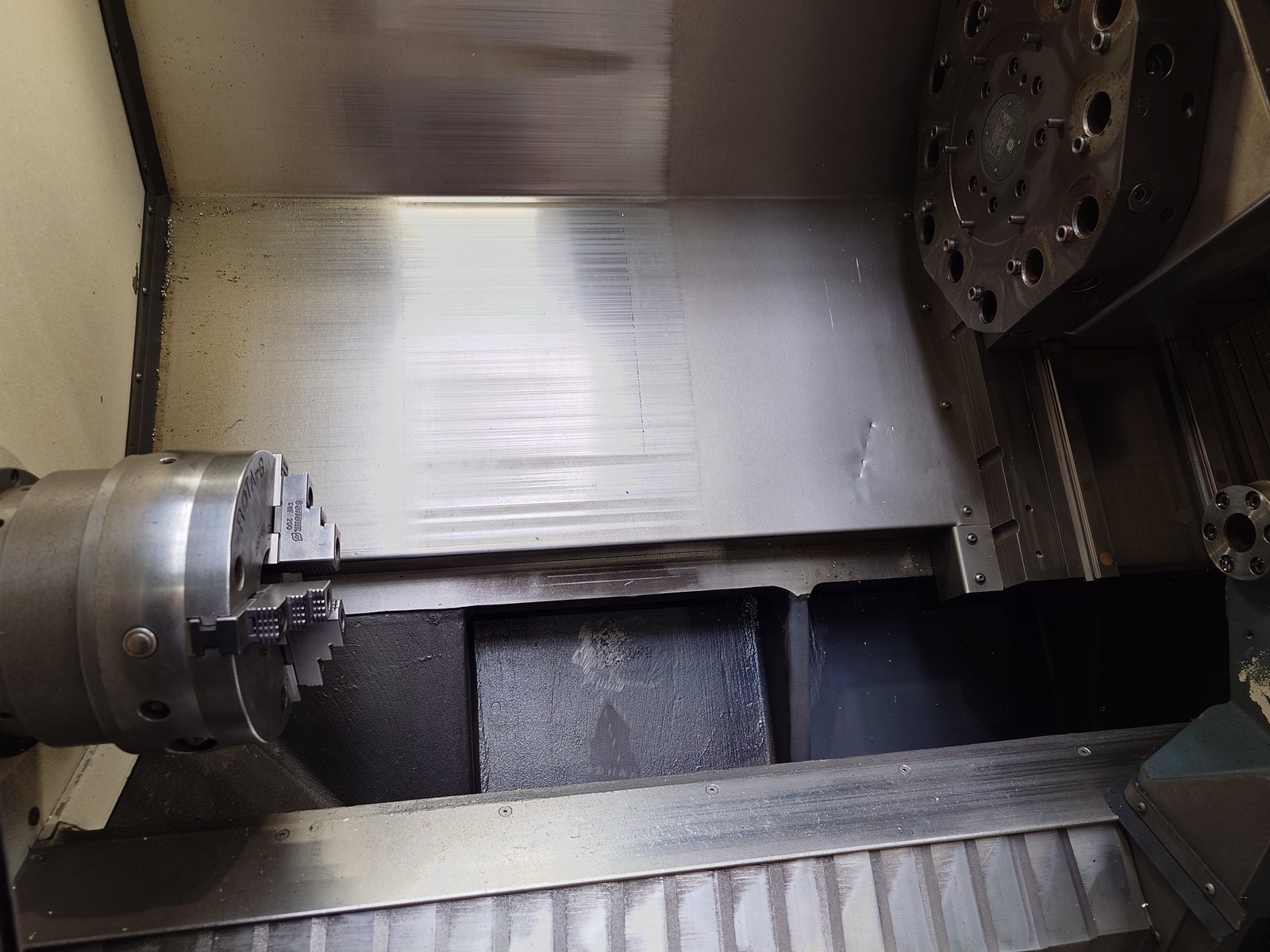

DMG MORI NEF 400 CNC turning center was built in 2009 in Poland by FAMOT Pleszew S.A. The machine, distinguished by its compact design and high efficiency, is used for precision machining of workpieces with a maximum diameter of 350 mm. The machining process is performed inside a fully illuminated workspace by means of a high-speed spindle and precision cutting tools taken from a 12-position turret. The extremely rigid design eliminates any vibration and oscillation, ensuring maximum process stability during even the most intense challenges. All these features make the DMG NEF 400 the best choice for any industrial plant.

The GILDEMEISTER NEF 400 CNC lathe was used for prototyping and worked for a total of 6492 hours. The offer also includes extensive equipment, consisting of, among others, an advanced HEIDENHAIN CNC control, driven tools and a chip conveyor.

Technical specifications of the DMG MORI NEF 400 metal lathe

- maximum turning diameter: 350 mm

- bar diameter: 52 mm

- swing over bed: 385 mm

- swing over slide: 350 mm

- maximum turning length: 650 mm

- distance between centers: 805 mm

- feed in the X/Z axis: 255/700 mm

- feed in the Z-axis (tailstock): 580 mm

- rapid traverse in the X,Z axis: 30 m/min

- thrust force in the X/Z axis (100% ED): 4.5/6.2 kN

- thrust force in the X/Z axis (40% ED): 5/8.5 kN

- maximum spindle rotational speed: 4000 rpm

- spindle bore diameter: 65 mm

- spindle diameter: 90 mm

- spindle drive power (100% ED/40% ED): 11.5/15.3 kW

- spindle torque (100% ED/ 40% ED): 293/390 Nm

- spindle end: A6 DIN 55026

- distance from spindle end to the floor: 1040 mm

- chuck diameter: 200 mm

- maximum turret rotational speed: 4500 rpm

- turret drive power (100% ED/ 40% ED): 3.3/4.4 kW

- turret torque (100% ED/ 40% ED): 16/21 Nm

- tool holder: VDI 30

- number of driven tools: 6

- tool shank cross-section: 20×20 mm

- tailstock extension: 580 mm

- tailstock taper: Morse MK4

- maximum tailstock thrust: 680 daN

- operating hours: 6492 h

- machine switch-on time: approx. 25750 h

- power supply: 400 V; 50/60 Hz

- dimensions (L with chip conveyor x W x H): 3800 x 2215 x 1990 mm

- weight of the DMG GILDEMEISTER NEF 400 machine: 3265 kg

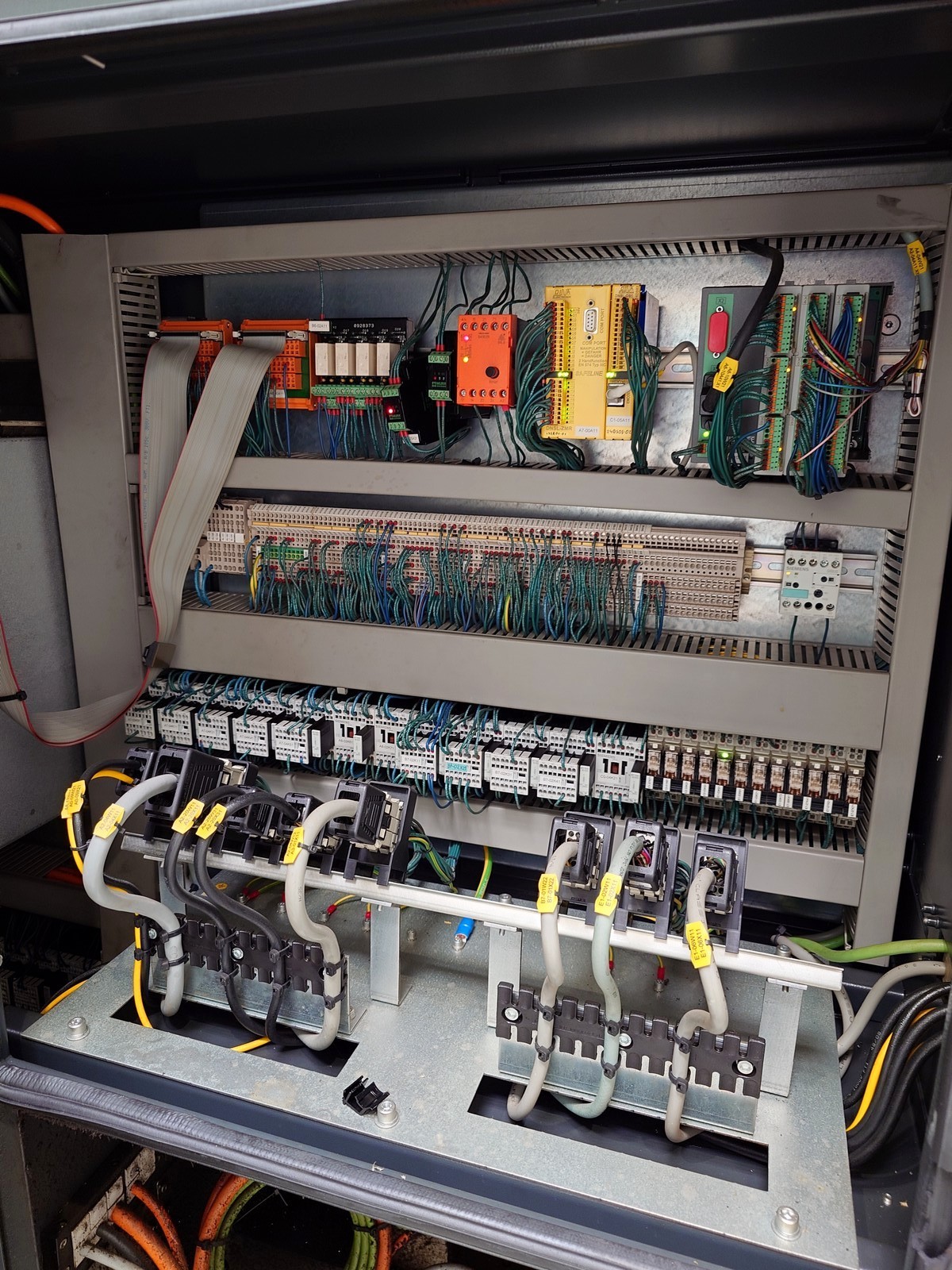

Equipment of the DMG MORI lathe

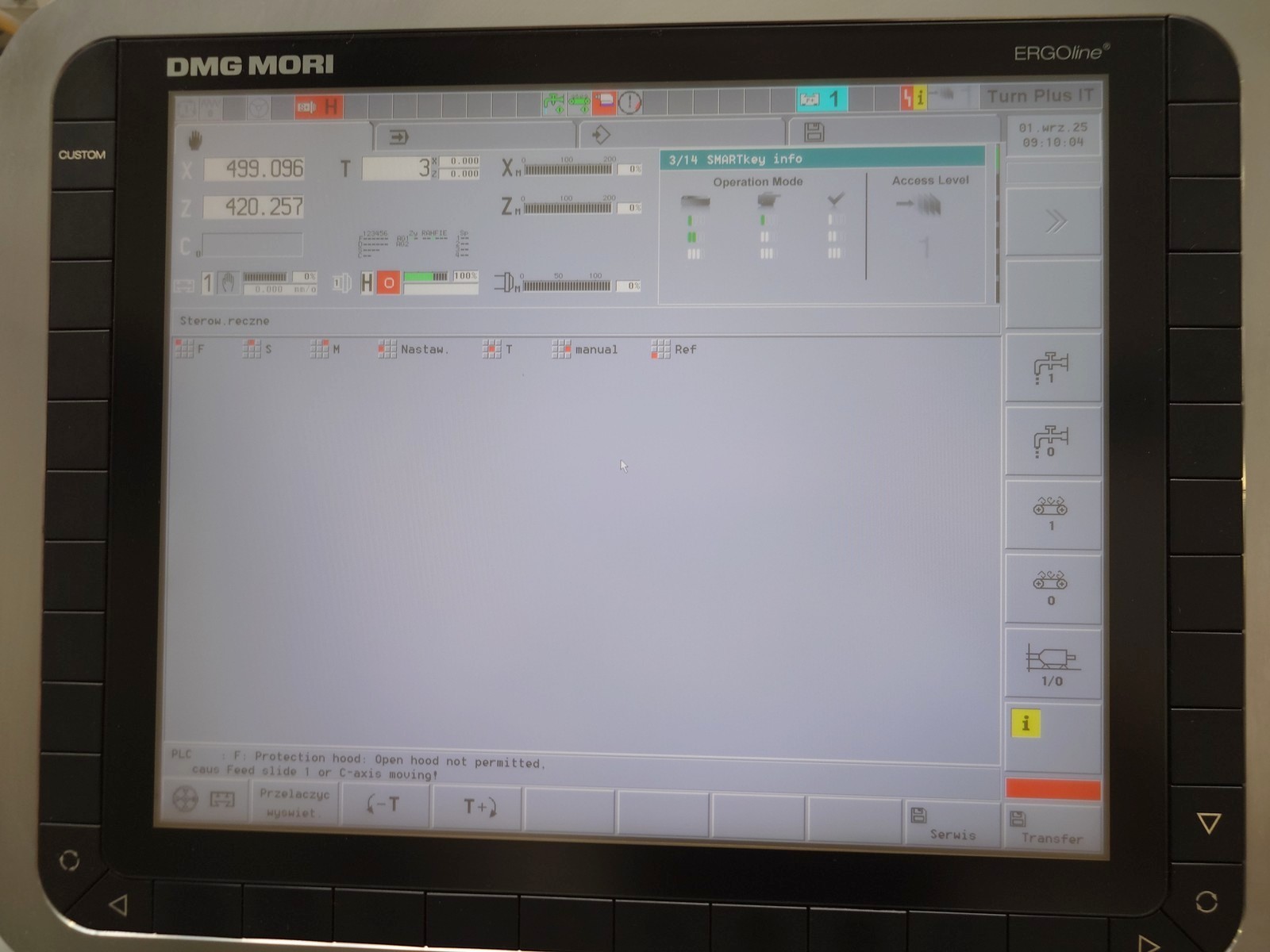

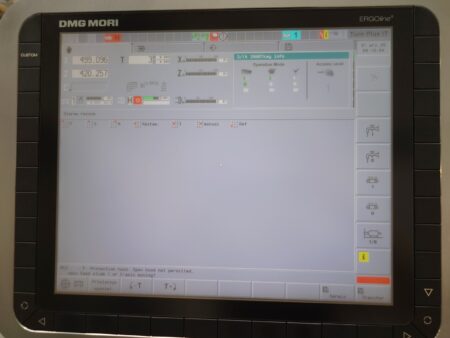

- CNC controller: HEIDENHAIN

- touch screen control panel: DMG MORI ERGOline

- SCHUNK chuck with quick-change jaws

- 12-position turret VDI 30

- driven tools

- C axis

- hydraulic tailstock

- chip conveyor

- chip tray 160 l

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe