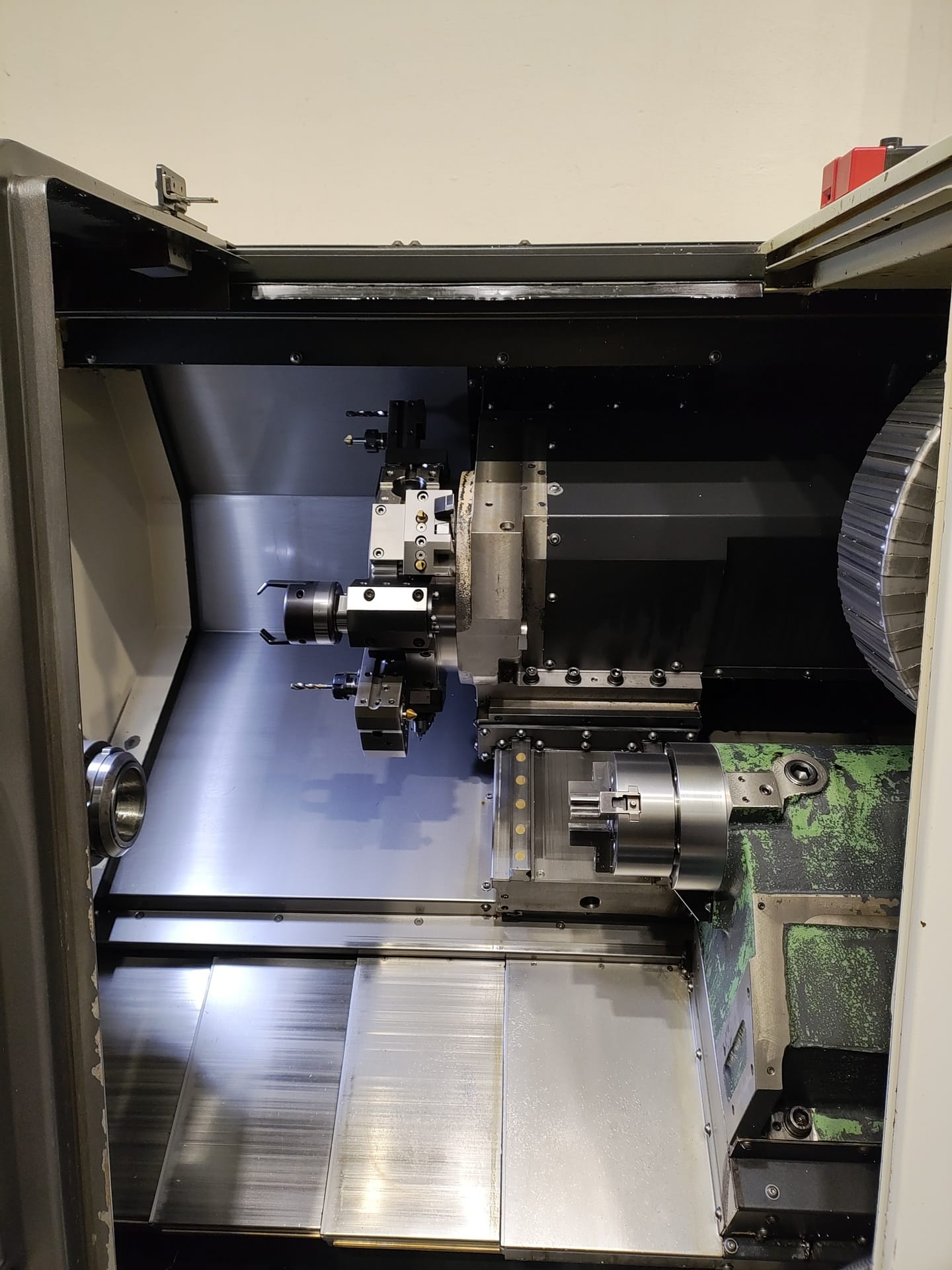

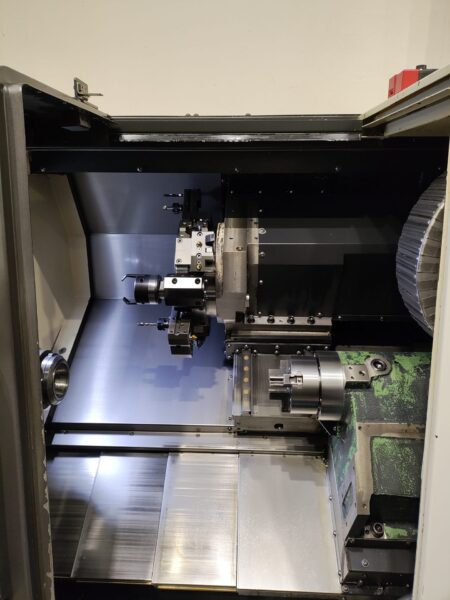

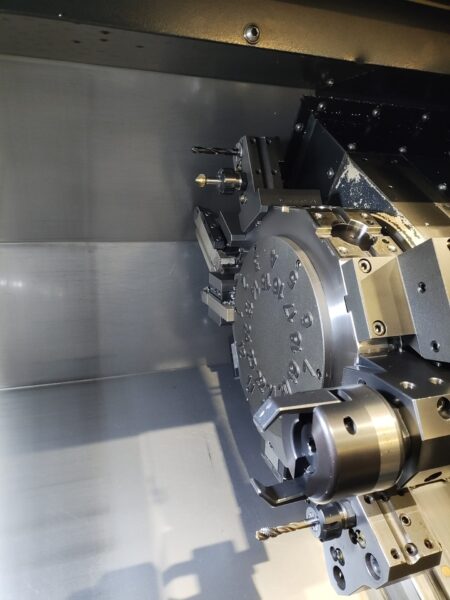

DOOSAN LYNX 220 LMSC CNC turning center was manufactured in 2015 in South Korea. This extremely efficient and reliable machine is able to streamline even the most demanding machining process in any production facility, thanks to the use of, among others, two high-speed spindles and an extremely stable design. Workpieces with a maximum diameter of 240 mm and a length of 510 mm are machined inside a large working area equipped with a specially designed bed. The bed effectively dampens all vibrations and oscillations, resulting in a better quality of the machined surface and increased service life of the cutting tools. To this date, the DOOSAN LYNX 220 dual-spindle CNC lathe has worked a total of 2198 hours and has been used exclusively for machining stainless steel. The total weight of the machine is 3400 kg.

Technical data of the DOOSAN LYNX 220 LMSC CNC lathe

General data

- feeds in X/Z/B axis: 165/550/550 mm

- rapid traverse in the X/Z/B axis: 30/36/30 m/min

- maximum turning diameter: 240 mm

- maximum turning length: 510 mm

- operating hours: 2198 h

- power supply: 3x 380 VAC; 50/60 Hz

- dimensions (L x W x H): 2763 x 1627 x 1655 mm

- weight of machine: 3400 kg

Main spindle

- maximum rotational speed: 4500 rpm

- chuck diameter: 210 mm

- bar diameter: 65 mm

- spindle end: A2-6

- drive power: 15 kW

- torque: 169 Nm

Sub-spindle

- maximum rotational speed: 6000 rpm

- chuck diameter: 135 mm

- bar diameter: 34 mm

- spindle tip: flat ⌀ 110 mm

- drive power: 5.5 kW

- torque: 35 Nm

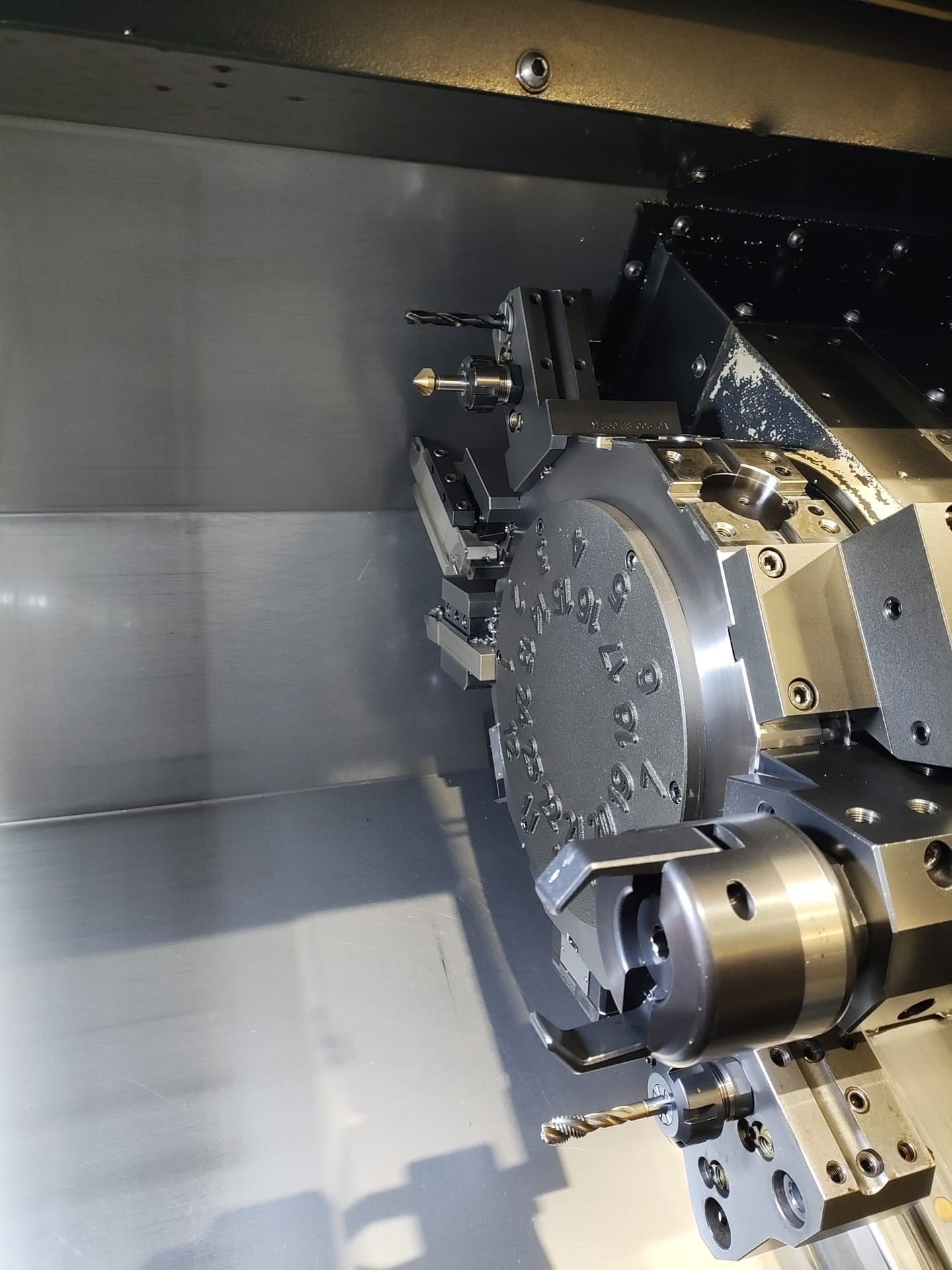

Tool head

- number of positions: 12 (24 index)

- maximum rotary tool speed: 6000 rpm

- tool diameter: 20 mm

- boring bar diameter: 32 mm

- head indexing time: 0.15 s

Equipment of the LYNX 220LMSC CNC turning center

- CNC control: DOOSAN FANUC i Series

- sub-spindle

- measuring probe

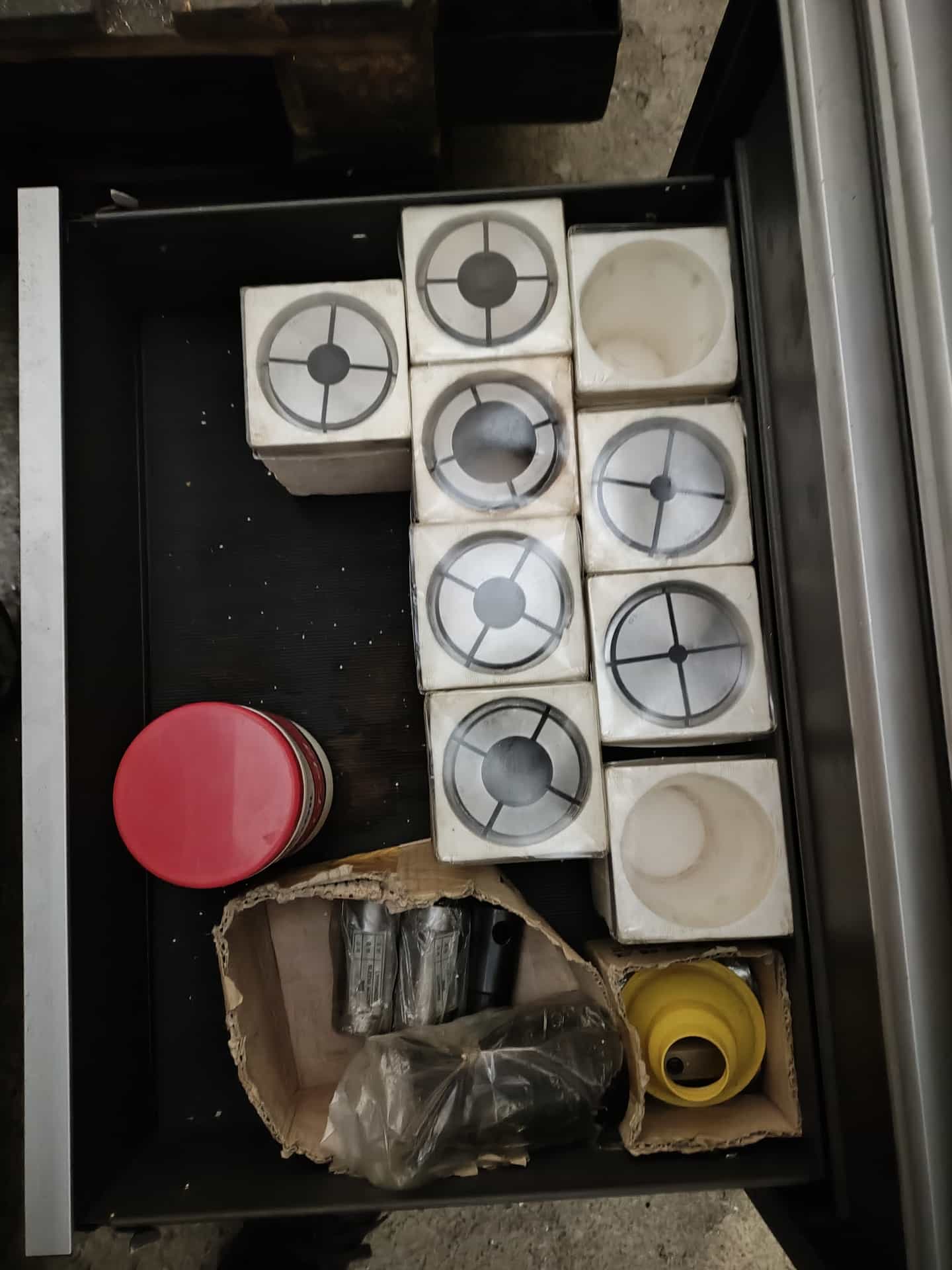

- set of toolholders

- gripper

- chip conveyor

- workpiece collecting basket

- foot switch controller

- feeding table BA-65

- workspace illumination

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe